Aytok DE-DD filters are manually cleaned filters. Almost all of the filter components are made of plastic raw materials. Non-plastic parts are made of stainless steel (AISI304). Therefore, the corrosion resistance of the filters is quite high. It is ensured that the filter performs its duty for years without corrosion.

General Characteristic

Body Material : PA

Cartridge Material: Disc Cartridge(PP), Screen Cartridge (SS 304+PA )

Maximum Working Pressure : 8 Bar (116 PSI)

Maximum Working Temperature: 60 °C/ 140 °F

Filtration Degree: 20-50-100-130 micron

Technical Specifications

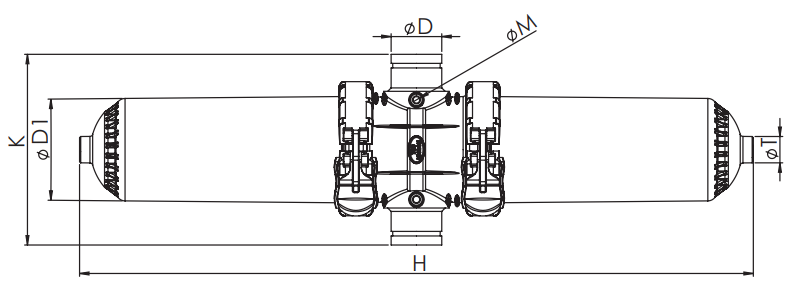

CODE D M T D1 H K FLOW FILTER

SURFACE AREA

WEIGHT inch mm m³/h cm² kg DD3 3 1/4 3/4 190 960 340 50 2604 11,4 DD4 4 1/4 3/4 190 960 340 70 2604 11,6 DDS3 3 1/4 3/4 190 1200 340 60 3610 13,6 DDS4 4 1/4 3/4 190 1200 340 80 3610 13,8 DE3 3 1/4 3/4 190 960 340 50 2280 8,4 DE4 4 1/4 3/4 190 960 340 70 2280 8,6 DES3 3 1/4 3/4 190 1200 365 60 3040 9,8 DES4 4 1/4 3/4 190 1200 365 80 3040 10

Working Princible and Washing Operation

The particles coming from water source and entering to the filter, are not allowed to be sent to the filter outlet after being filtered through screen. These particles accumulate on the inner surface of the screen and a dirty layer is formed. This contamination event increases the pressure difference between the inlet and outlet of the filter. The pressure difference between the inlet and outlet is observed manually from the manometers. If the pressure difference increases, the water flow is cut off and the system is stopped. The clamps on the filter are opened and the cover is removed. Then the screen catridge is takenout cleaned bu using pressurized water and reassembled.

The particles coming from water source and entering to the filter, are not allowed to be sent to the filter outlet after being filtered through discs. These particles accumulate on the outer surface of the discs and form a dirty layer. This contamination event increases the pressure difference between the inlet and outlet of the filter. If the pressure difference increases, the water flow is cut off and the system is stopped. The clamps on the filter are opened and the cover is removed. Then the disc cartridge is taken out and the plastic clamp lever is loosened and the discs are opened. It is cleaned bu using pressurized water and reassembled.