MPE

| Body Material | PP |

| Cartridge Material | SS304L, PP |

| Maximum Working Pressure | 8 bar ; 116 Psi |

| Maximum Working Temperature | 60 °C ; 140°F |

| Filtration Sensitivity | 80, 100, 130, 200 μ (micron) |

Aranıyor...

Farklı kelimeler deneyebilirsiniz

Bizimle iletişime geçmek için aşağıdaki formu doldurun.

Basınç farkı, giriş ve çıkış manometreleri aracılığıyla manuel olarak izlenir. Basınçtaki artış, temizlik ihtiyacını gösterir. Başlamak için, su kaynağını kapatın ve sistemi basınçsız hale getirin. Ardından, kapağı çıkarın ve filtre kartuşunu dışarı alın. Elek filtre elemanı, basınçlı su ile doğrudan temizlenir. Temizlendikten sonra, filtre yeniden monte edilir ve kullanıma hazır hale gelir.

Su filtreye girer ve filtreleme elemanından (ince bir elek) geçer. Çalışma sırasında, kirleticiler yavaş yavaş bu elemanın yüzeyinde (eleklerin iç yüzeyinde) birikir. Bu birikim su akışını engeller ve filtrenin giriş ve çıkışı arasında bir basınç farkı oluşturur. Bu basınç farkı 0,7 bar'a ulaştığında manuel temizlik gereklidir.

| Body Material | PP |

| Cartridge Material | SS304L, PP |

| Maximum Working Pressure | 8 bar ; 116 Psi |

| Maximum Working Temperature | 60 °C ; 140°F |

| Filtration Sensitivity | 80, 100, 130, 200 μ (micron) |

Basınç farkı, giriş ve çıkış manometreleri aracılığıyla manuel olarak izlenir. Basınçtaki artış, temizlik ihtiyacını gösterir. Başlamak için, su kaynağını kapatın ve sistemi basınçsız hale getirin. Ardından, kapağı çıkarın ve filtre kartuşunu dışarı alın. Elek filtre elemanı, basınçlı su ile doğrudan temizlenir. Temizlendikten sonra, filtre yeniden monte edilir ve kullanıma hazır hale gelir.

Su filtreye girer ve filtreleme elemanından (ince bir elek) geçer. Çalışma sırasında, kirleticiler yavaş yavaş bu elemanın yüzeyinde (eleklerin iç yüzeyinde) birikir. Bu birikim su akışını engeller ve filtrenin giriş ve çıkışı arasında bir basınç farkı oluşturur. Bu basınç farkı 0,7 bar'a ulaştığında manuel temizlik gereklidir.

Dar alanlarda verimlilik için tasarlanan Aytok MPE filtreleri, düşük akışlı su sistemleri için sağlam ve çok yönlü bir çözüm sunar. Bahçe sulaması, gübreleme ve küçük ölçekli soğutma ekipmanlarının korunması gibi uygulamalar için mükemmeldir.

| Body Material | PP |

| Cartridge Material | SS304L, PP |

| Maximum Working Pressure | 8 bar ; 116 Psi |

| Maximum Working Temperature | 60 °C ; 140°F |

| Filtration Sensitivity | 80, 100, 130, 200 μ (micron) |

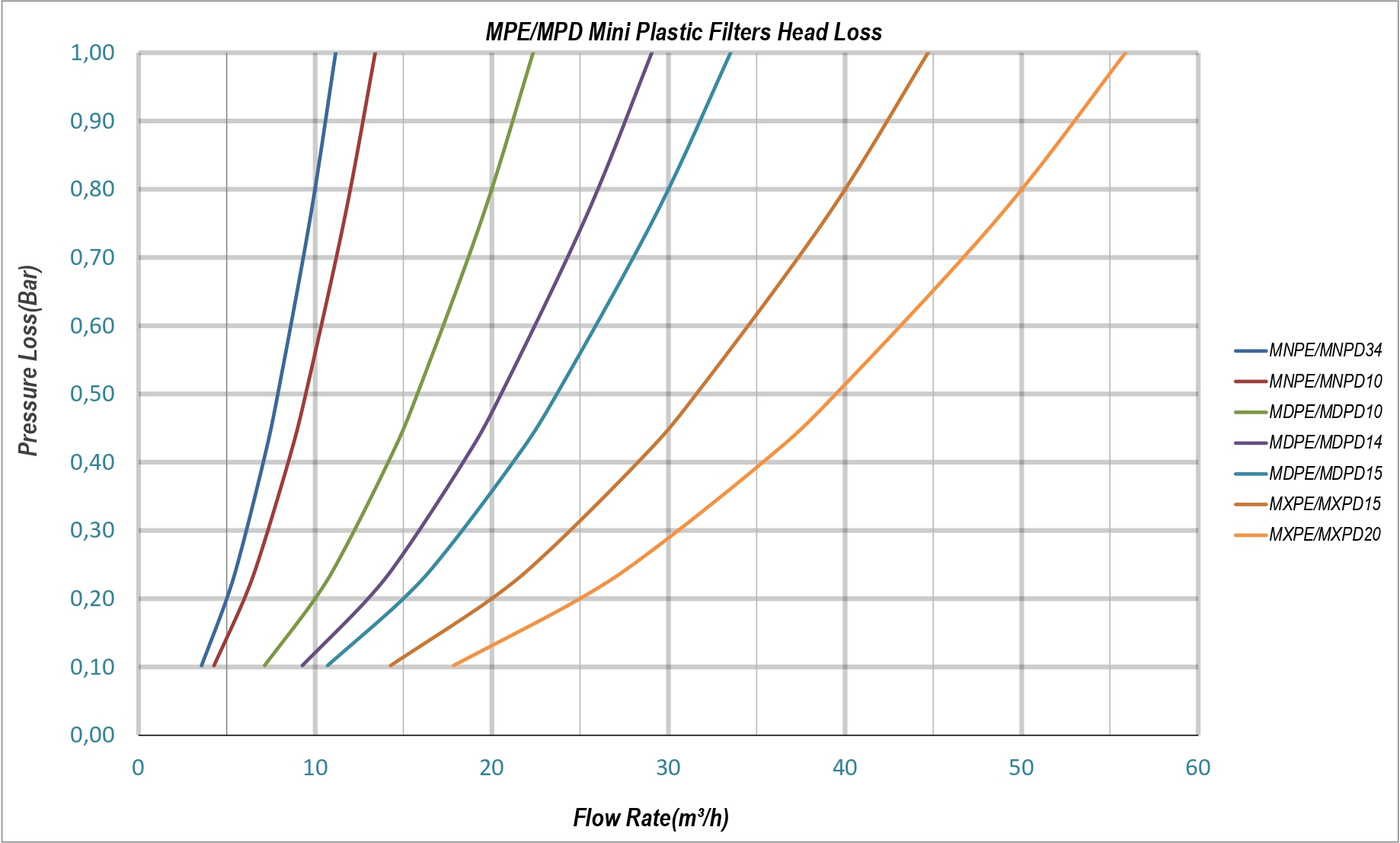

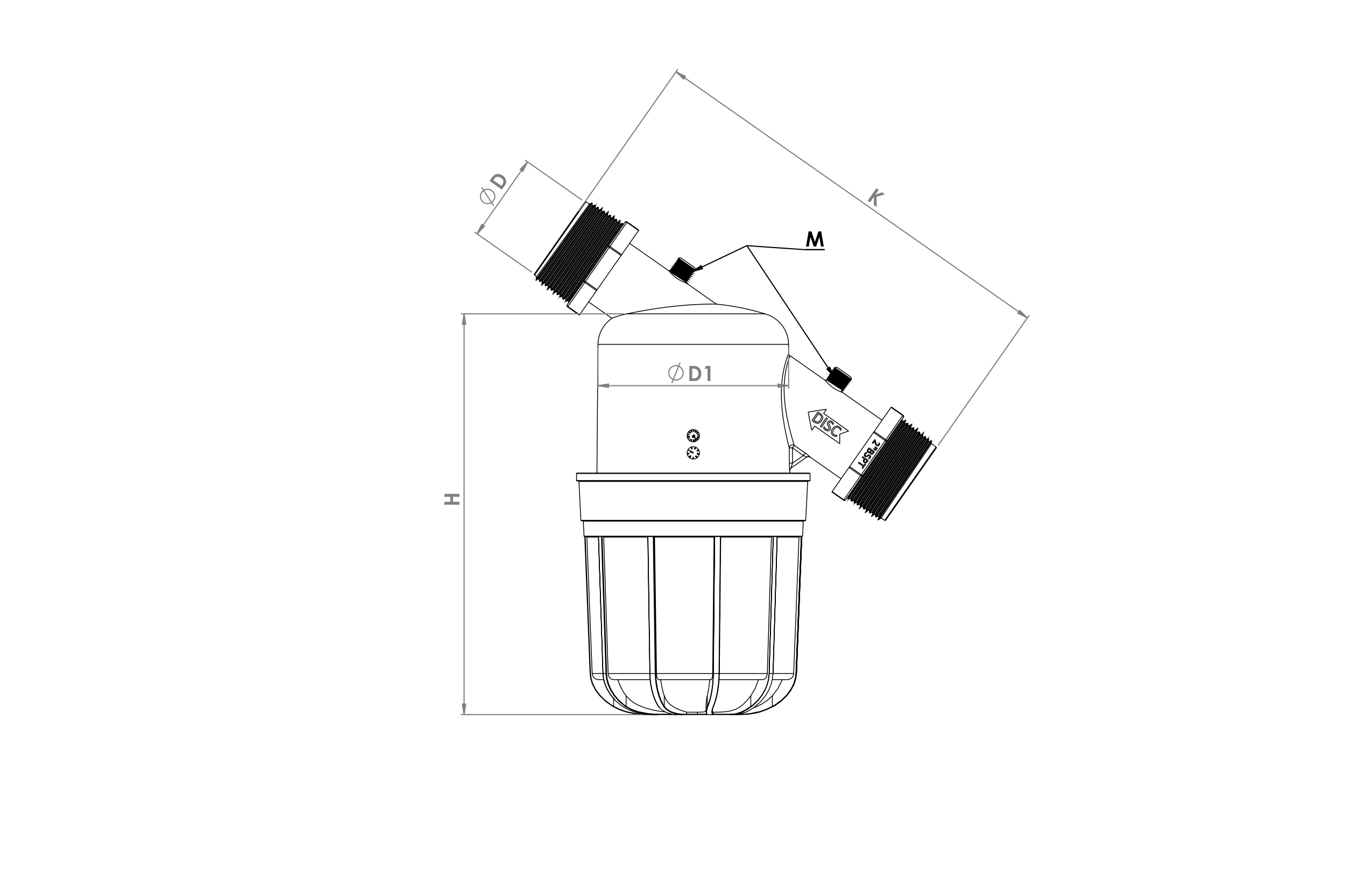

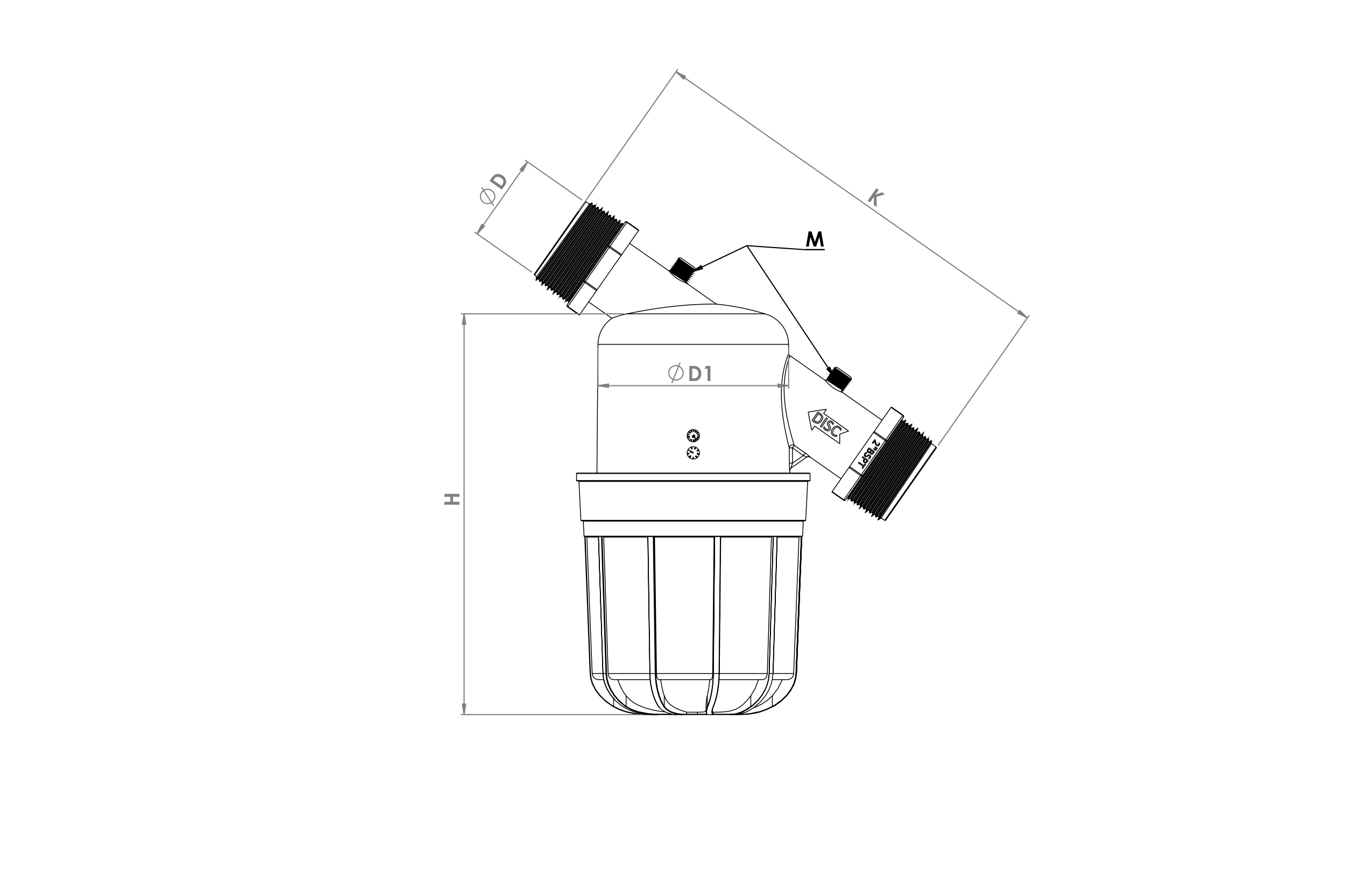

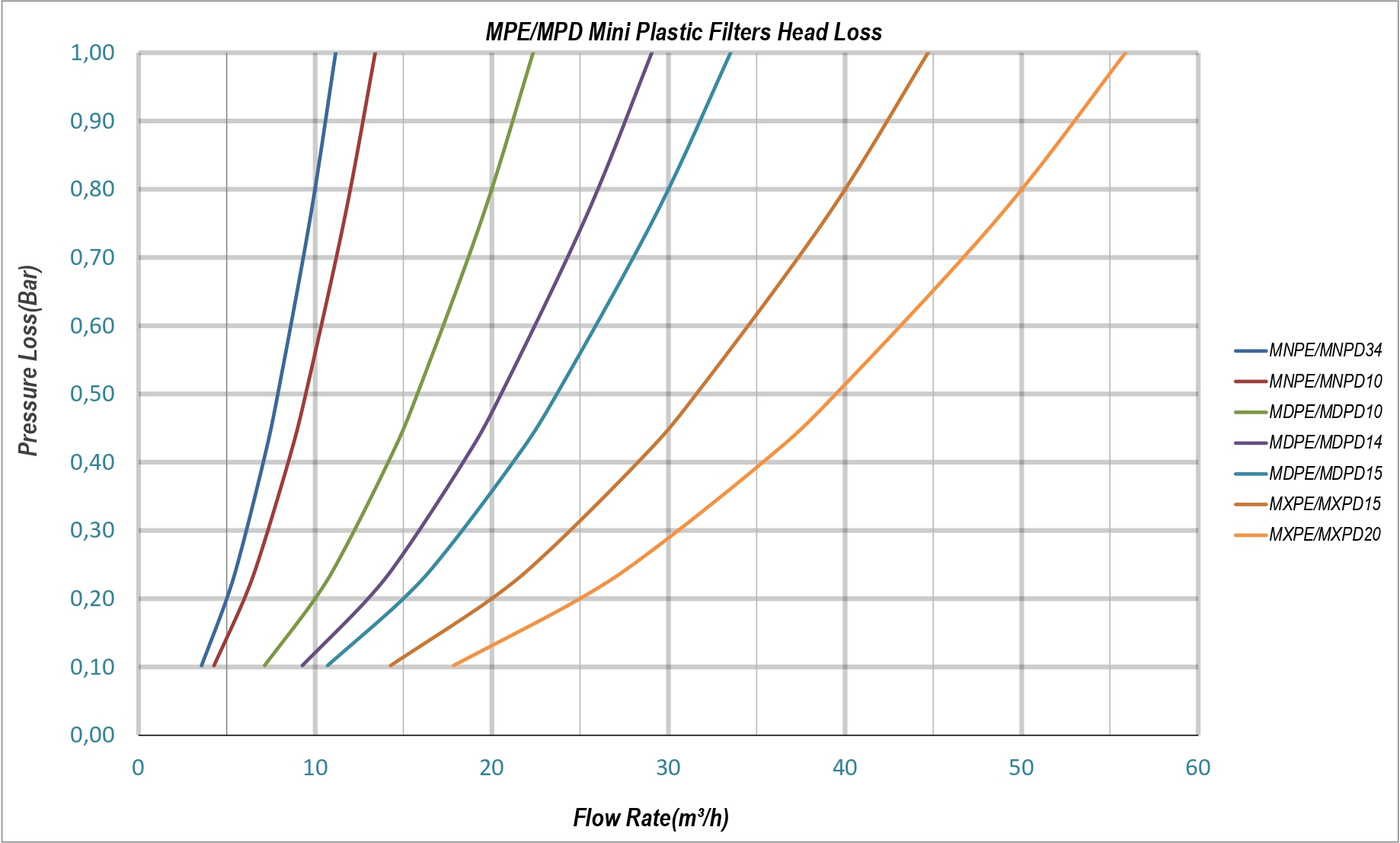

| KOD | (D) | (M) (İnç) |

(T) (İnç) |

D1 | H | K | Ana Hat Debisi | Filtreleme Alanı cm² |

Ağırlık kg |

||

|---|---|---|---|---|---|---|---|---|---|---|---|

| İnç | DN | mm | mm | mm | m³/h | GPM(US) | |||||

| MNPE34 | 3/4 | 20 | - | 3/4 | 68 | 190 | 160 | 5 | 22 | 165 | 0,3 |

| MNPE10 | 1 | 25 | - | 3/4 | 68 | 190 | 160 | 6 | 26,4 | 165 | 0,3 |

| MDPE10 | 1 | 25 | - | 3/4 | 96 | 230 | 220 | 10 | 44 | 300 | 0,75 |

| MDPE14 | 1 1/4 | 32 | - | 3/4 | 96 | 230 | 220 | 13 | 66 | 300 | 0,75 |

| MDPE15 | 1 1/2 | 40 | - | 3/4 | 96 | 230 | 220 | 15 | 66 | 300 | 0,75 |

| MXPE15 | 1 1/2 | 40 | 1/4 | 3/4 | 120 | 280 | 270 | 20 | 88 | 515 | 1,2 |

| MXPE20 | 2 | 50 | 1/4 | 3/4 | 120 | 280 | 270 | 25 | 110 | 515 | 1,2 |

Bizimle iletişime geçmek için aşağıdaki formu doldurun.

| Body Material | PP |

| Cartridge Material | SS304L, PP |

| Maximum Working Pressure | 8 bar ; 116 Psi |

| Maximum Working Temperature | 60 °C ; 140°F |

| Filtration Sensitivity | 80, 100, 130, 200 μ (micron) |

Basınç farkı, giriş ve çıkış manometreleri aracılığıyla manuel olarak izlenir. Basınçtaki artış, temizlik ihtiyacını gösterir. Başlamak için, su kaynağını kapatın ve sistemi basınçsız hale getirin. Ardından, kapağı çıkarın ve filtre kartuşunu dışarı alın. Elek filtre elemanı, basınçlı su ile doğrudan temizlenir. Temizlendikten sonra, filtre yeniden monte edilir ve kullanıma hazır hale gelir.

Su filtreye girer ve filtreleme elemanından (ince bir elek) geçer. Çalışma sırasında, kirleticiler yavaş yavaş bu elemanın yüzeyinde (eleklerin iç yüzeyinde) birikir. Bu birikim su akışını engeller ve filtrenin giriş ve çıkışı arasında bir basınç farkı oluşturur. Bu basınç farkı 0,7 bar'a ulaştığında manuel temizlik gereklidir.

Dar alanlarda verimlilik için tasarlanan Aytok MPE filtreleri, düşük akışlı su sistemleri için sağlam ve çok yönlü bir çözüm sunar. Bahçe sulaması, gübreleme ve küçük ölçekli soğutma ekipmanlarının korunması gibi uygulamalar için mükemmeldir.

| KOD | (D) | (M) (İnç) |

(T) (İnç) |

D1 | H | K | Ana Hat Debisi | Filtreleme Alanı cm² |

Ağırlık kg |

||

|---|---|---|---|---|---|---|---|---|---|---|---|

| İnç | DN | mm | mm | mm | m³/h | GPM(US) | |||||

| MNPE34 | 3/4 | 20 | - | 3/4 | 68 | 190 | 160 | 5 | 22 | 165 | 0,3 |

| MNPE10 | 1 | 25 | - | 3/4 | 68 | 190 | 160 | 6 | 26,4 | 165 | 0,3 |

| MDPE10 | 1 | 25 | - | 3/4 | 96 | 230 | 220 | 10 | 44 | 300 | 0,75 |

| MDPE14 | 1 1/4 | 32 | - | 3/4 | 96 | 230 | 220 | 13 | 66 | 300 | 0,75 |

| MDPE15 | 1 1/2 | 40 | - | 3/4 | 96 | 230 | 220 | 15 | 66 | 300 | 0,75 |

| MXPE15 | 1 1/2 | 40 | 1/4 | 3/4 | 120 | 280 | 270 | 20 | 88 | 515 | 1,2 |

| MXPE20 | 2 | 50 | 1/4 | 3/4 | 120 | 280 | 270 | 25 | 110 | 515 | 1,2 |