| Valve Body Material | GGG40 |

| Diaphragm Material | Natural Rubber |

| Shaft Material | Stainless Steel |

| Minimum Working Pressure | 1 bar ; 14.5 Psi |

| Maximum Working Pressure | 16 bar ; 232 Psi |

| Painting Method | Electrostatic Powder Coating |

| Painting Material | Epoxy Polyester |

Ürün Detayı

Cast Body Backwash Valves

GENERAL FEATURES

Working Principle

The primary function of a backwash valve is to effectively clean the filter, creating a buzzing sound. When a backwash signal is provided, the valve automatically reconfigures the flow path: it closes off the incoming dirty water while simultaneously opening it to a seal. This forces trapped particles out of the rest of the system, forcing them back into the filter through the newly opened drain hole. This cycle effectively recycles the filter, ensuring the valve maintains its normal operation.

ADVANTAGES

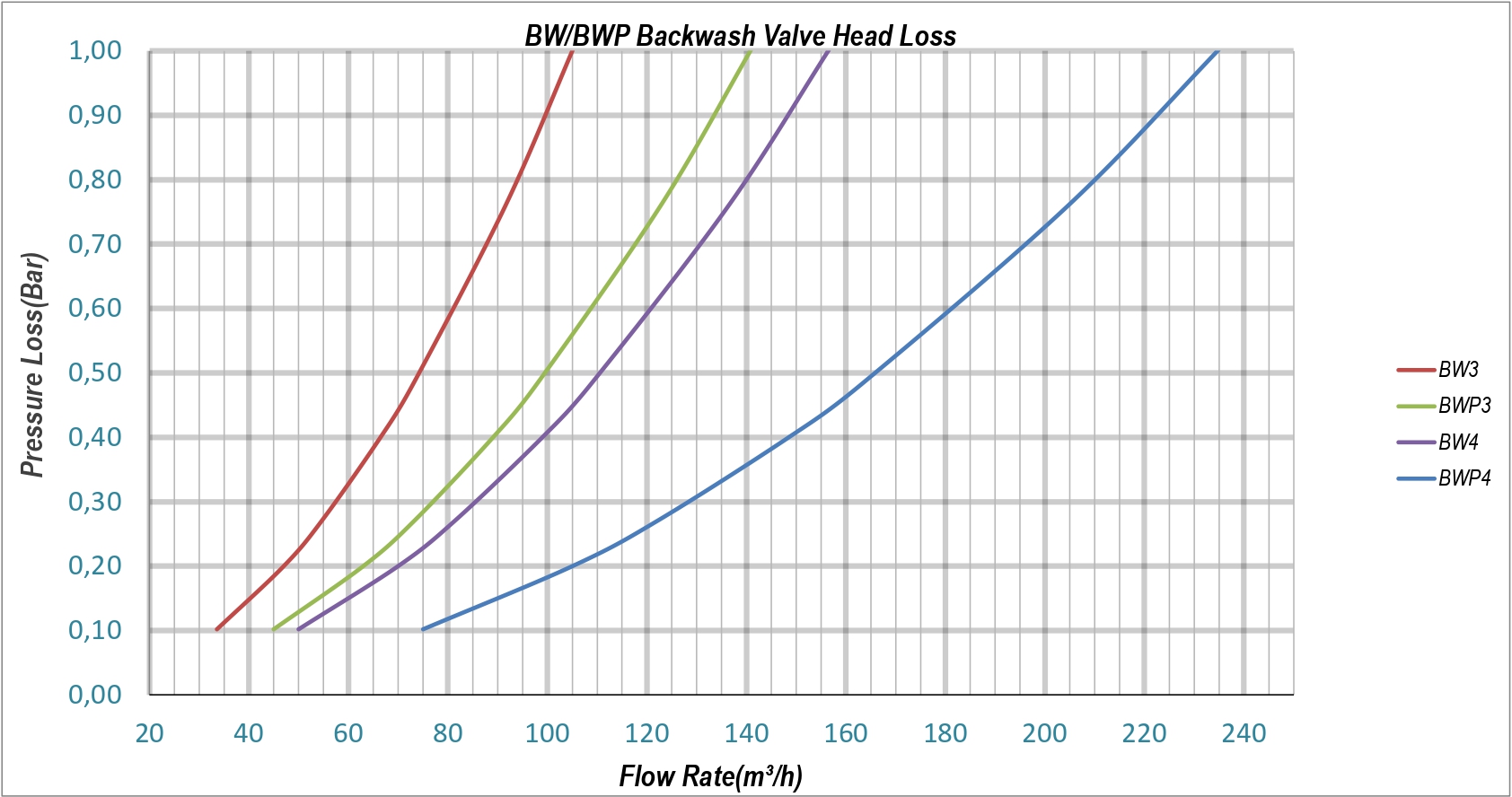

Superior Flow Dynamics: The extra-wide body design ensures maximum permeability, enabling powerful and effective backwashing with minimal flow restrictions. Heavy-Duty Ductile Iron Body: Manufactured from high-quality GGG40 ductile iron, these valves offer exceptional strength, impact resistance, and long-term durability, even under the most demanding conditions. Optimized Energy Efficiency: Designed for hydraulics, our valves minimize pressure loss throughout the system. This reduces the load on your pumps, resulting in significant energy savings and lower operating costs. Simplified Installation and Maintenance: Designed with a user-friendly structure and a minimum number of accessories, these valves significantly shorten installation time and make routine maintenance quick, easy and convenient.

Powerful Filtration, Smarter Design.

The Heart of Your Filtration System. Strong, Simple, and Long-Lasting.

Don't let a weak valve be the weak link in your filtration system. Our Cast Iron Backwash Valves are designed for one purpose: to deliver reliable and powerful performance when it matters most. Forget high energy bills, complicated maintenance, and reliability concerns. It's a durable solution you can install and rely on.

DÖKÜMANLAR

| CODE | Drain Connection Type (T) |

Inlet/Outlet (D) |

Dimensions | Max. Flow Rate | Flow Coefficient |

Operating |

|||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Inch | DN | mm | m³/h | GPM(US) | kv | cv | Bar | °C (°F) | |||||

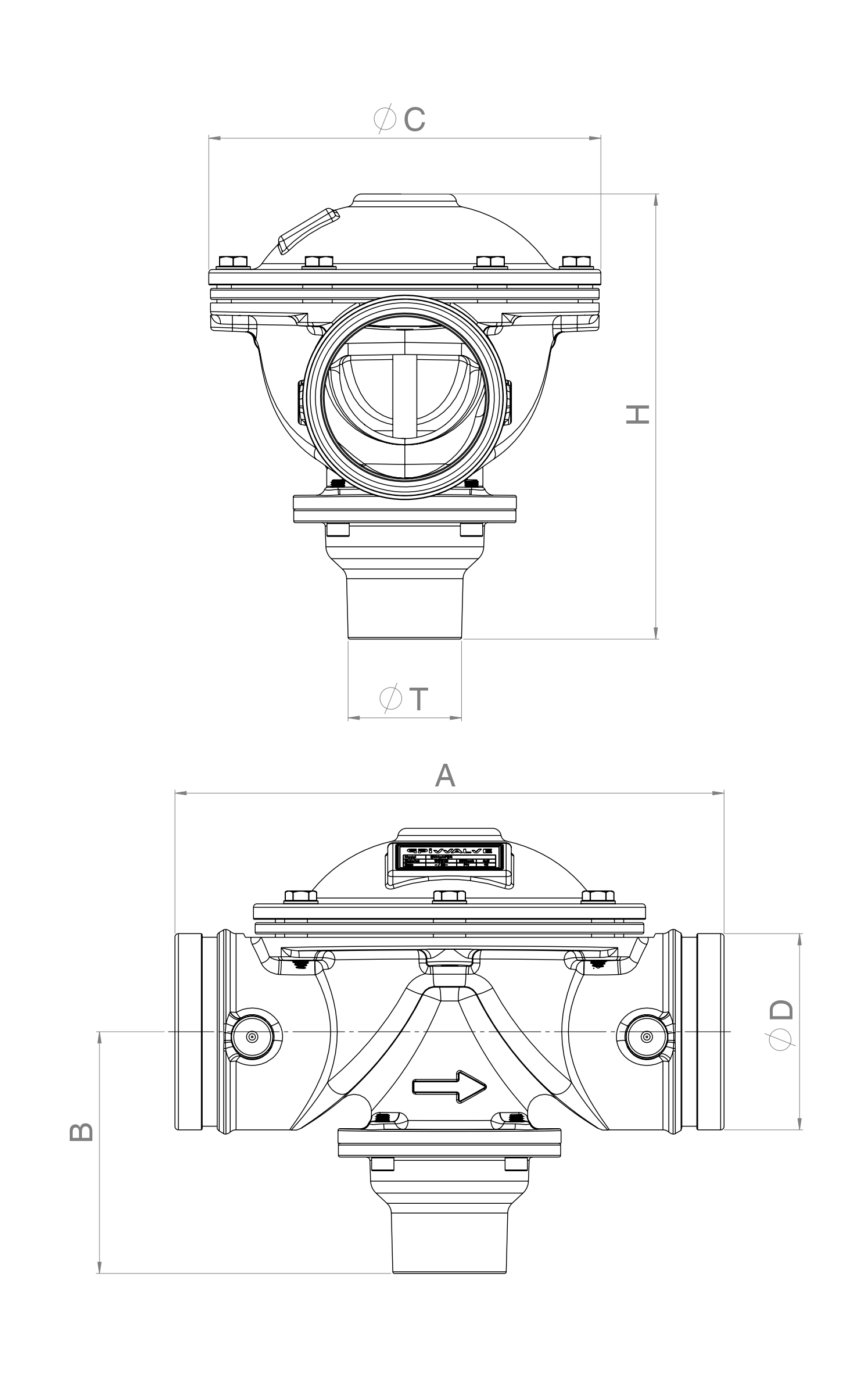

| A | B | C | H | ||||||||||

| BW3X3IG2 | Coupling 2" (DN50) | 3 | 80 | 290 | 138 | 190 | 229 | 80 | 352 | 113 | 130 | 1-16 | 60(140) |

| BW3X3IF2 | Threaded 2" | 3 | 80 | 290 | 138 | 190 | 229 | 80 | 352 | 113 | 130 | 1-16 | 60(140) |

| BW3X3IG2 1/2 | Coupling 2 1/2" (DN65) | 3 | 80 | 290 | 134 | 190 | 225 | 80 | 352 | 113 | 130 | 1-16 | 60(140) |

| BWP3X3IF2 | Threaded 2" | 3 | 80 | 294 | 151 | 229 | 260 | 90 | 396 | 127 | 146 | 1-16 | 60(140) |

| BWP3X3IG2 | Coupling 2" (DN50) | 3 | 80 | 294 | 151 | 229 | 260 | 90 | 396 | 127 | 146 | 1-16 | 60(140) |

| BWP3X3IG2 1/2 | Coupling 2 1/2" (DN65) | 3 | 80 | 294 | 147 | 229 | 341 | 90 | 396 | 127 | 146 | 1-16 | 60(140) |

| BW4X4IG2 | Coupling 2" (DN50) | 4 | 100 | 320 | 140 | 229 | 259 | 105 | 462 | 148 | 170 | 1-16 | 60(140) |

| BW4X4IF2 | Threaded 2" | 4 | 100 | 320 | 142 | 229 | 261 | 105 | 462 | 148 | 170 | 1-16 | 60(140) |

| BW4X4IG2 1/2 | Coupling 2 1/2" (DN65) | 4 | 100 | 320 | 142 | 229 | 261 | 105 | 462 | 148 | 170 | 1-16 | 60(140) |

| BWP4X4IF3 | Threaded 3" | 4 | 100 | 340 | 226 | 260 | 341 | 135 | 594 | 190 | 218 | 1-16 | 60(140) |

| BWP4X4IG3 | Coupling 3" (DN80) | 4 | 100 | 340 | 226 | 260 | 341 | 135 | 594 | 190 | 218 | 1-16 | 60(140) |