| Body Material | PA6GFR30 |

| Cartridge Material | SS304L, PA6GFR30 |

| Maximum Working Pressure | 8 bar ; 116 Psi |

| Maximum Working Temperature | 60 °C ; 140°F |

| Filtration Sensitivity | 20-2000 μ (micron) |

Ürünlerimiz

water_drop Irrigation

Uygulama Alanları

water_drop IRRIGATION

Filter Türleri

Media Center

Send us a message

Fill out the form below to contact us.

Cleaning Process

The pressure differential is manually monitored via the inlet and outlet manometers. An increase in pressure indicates the need for cleaning. To begin, shut off the water supply and depressurize the system. Then, remove the cover and extract the filter cartridge. The cartridge’s retaining screw must be loosened to separate the discs for a thorough cleaning with pressurized water. After cleaning, the filter is reassembled and ready for service.

Working Principle

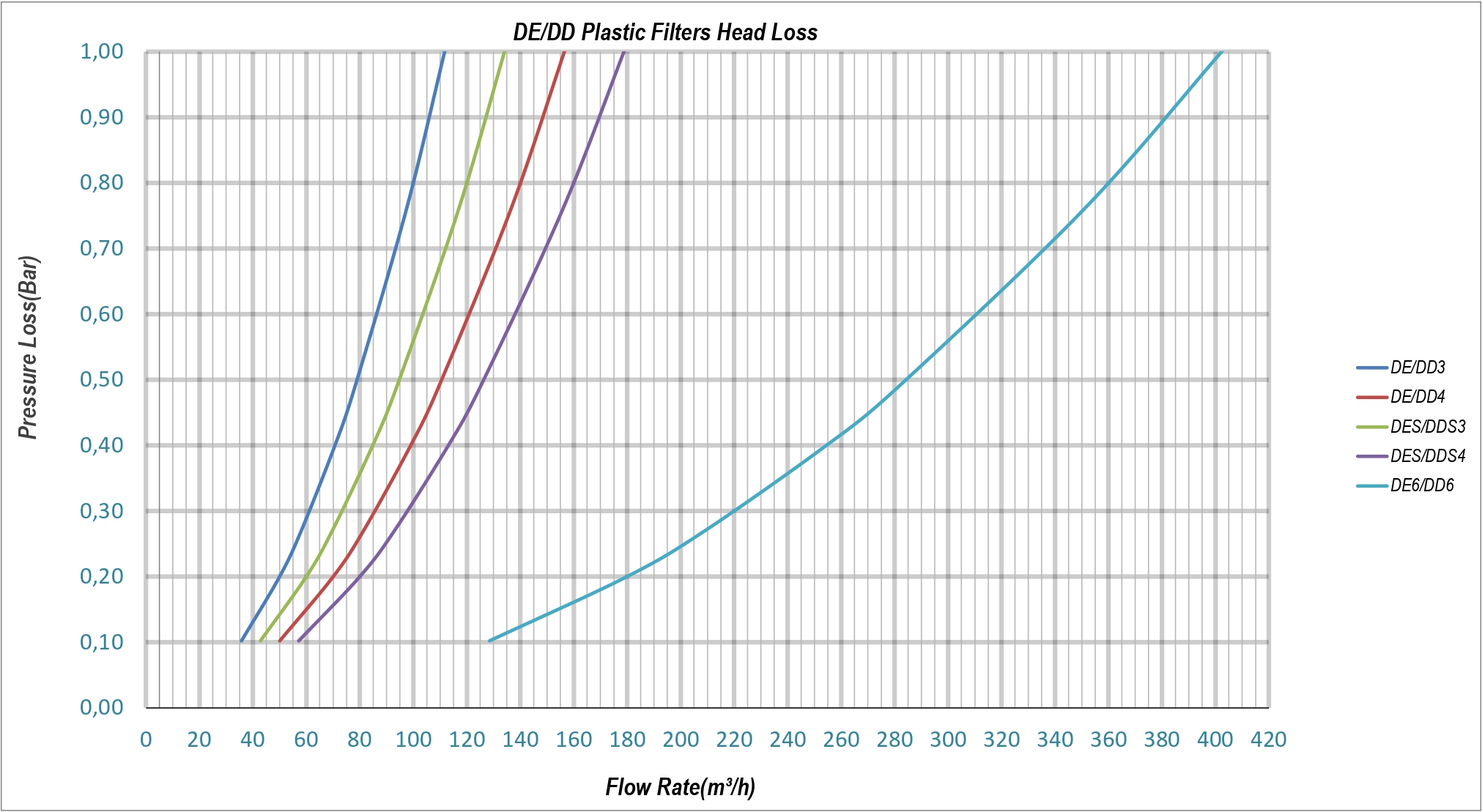

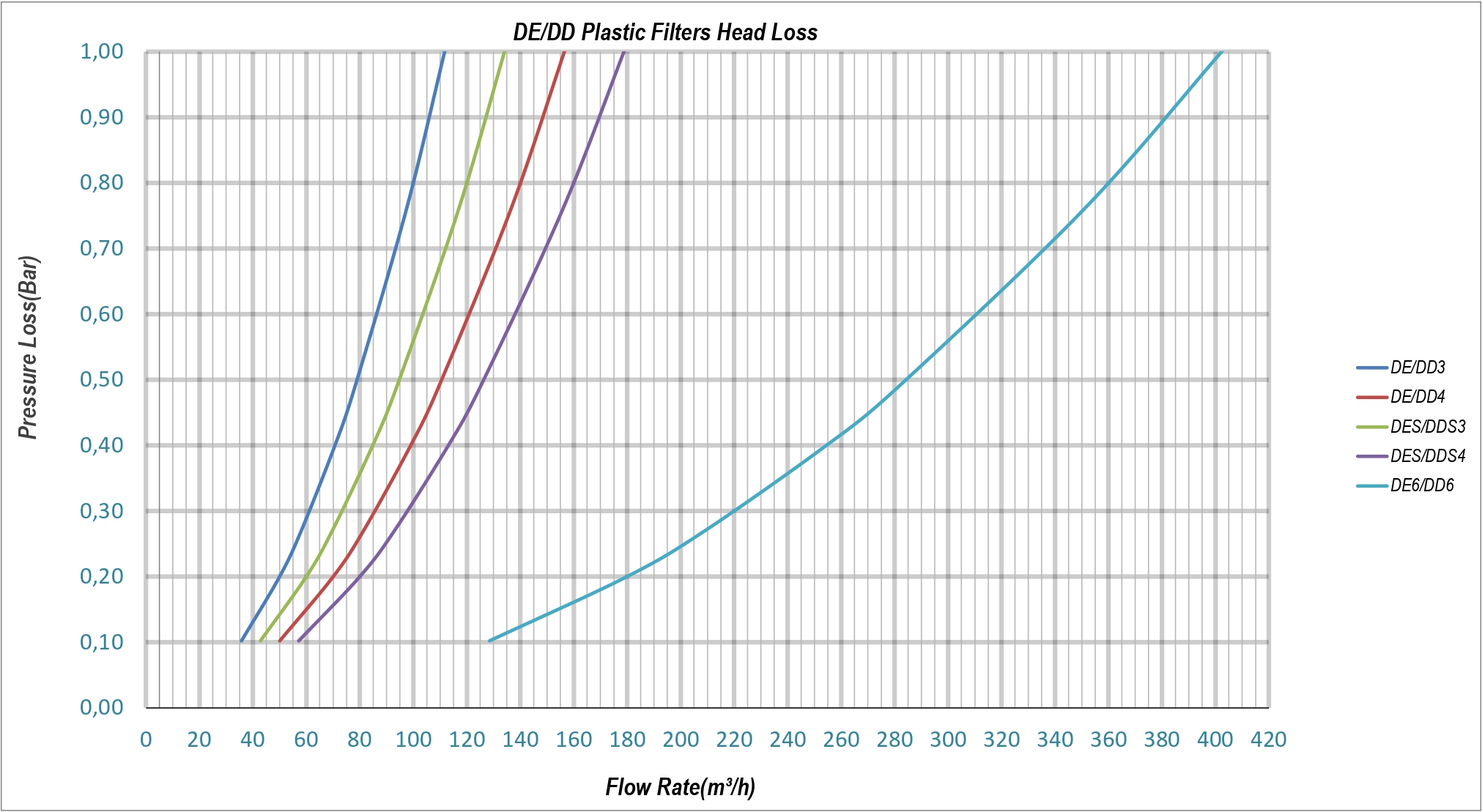

Water enters the filter and passes through the filtration element (a set of discs). During operation, contaminants gradually accumulate on the surface of this element—the outer surface for discs. This buildup obstructs the water flow, creating a pressure differential between the filter’s inlet and outlet. Manual cleaning is required when this pressure differential reaches 0.7 bar

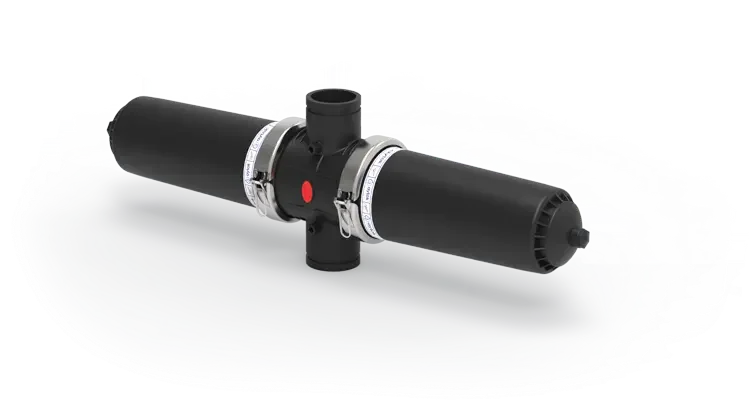

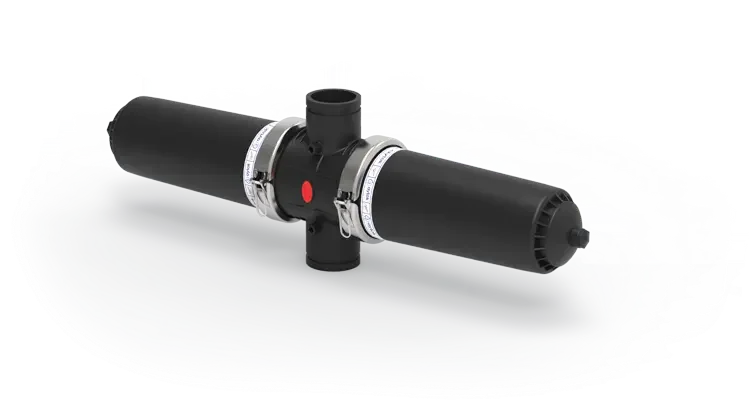

DD Series - Plastic Manual Double Disc Filters

GENERAL FEATURES

| Body Material | PA6GFR30 |

| Cartridge Material | SS304L, PA6GFR30 |

| Maximum Working Pressure | 8 bar ; 116 Psi |

| Maximum Working Temperature | 60 °C ; 140°F |

| Filtration Sensitivity | 20-2000 μ (micron) |

ADVANTAGES

Cleaning Process

The pressure differential is manually monitored via the inlet and outlet manometers. An increase in pressure indicates the need for cleaning. To begin, shut off the water supply and depressurize the system. Then, remove the cover and extract the filter cartridge. The cartridge’s retaining screw must be loosened to separate the discs for a thorough cleaning with pressurized water. After cleaning, the filter is reassembled and ready for service.

Working Principle

Water enters the filter and passes through the filtration element (a set of discs). During operation, contaminants gradually accumulate on the surface of this element—the outer surface for discs. This buildup obstructs the water flow, creating a pressure differential between the filter’s inlet and outlet. Manual cleaning is required when this pressure differential reaches 0.7 bar

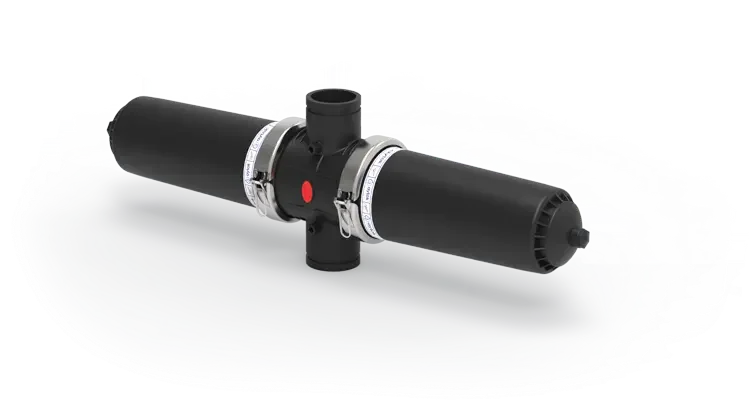

DD Series - Plastic Manual Double Disc Filters

ADVANTAGES

Double the Capacity. Uncompromised Reliability.

The Aytok DD Series manual disc filters are engineered with legendary durability to meet the highest operational demands. Their smart dual-body design doubles the filtration surface, enabling significantly higher flow rates while drastically reducing cleaning frequency, even under challenging water conditions. Manufactured with a robust polyamide body, the DD Series is designed to deliver reliable disc filtration performance with excellent resistance to pressure fluctuations and varying water quality. This advanced and versatile design guarantees years of trouble-free operation, providing superior reliability for your most demanding applications.

GENERAL FEATURES

| Body Material | PA6GFR30 |

| Cartridge Material | SS304L, PA6GFR30 |

| Maximum Working Pressure | 8 bar ; 116 Psi |

| Maximum Working Temperature | 60 °C ; 140°F |

| Filtration Sensitivity | 20-2000 μ (micron) |

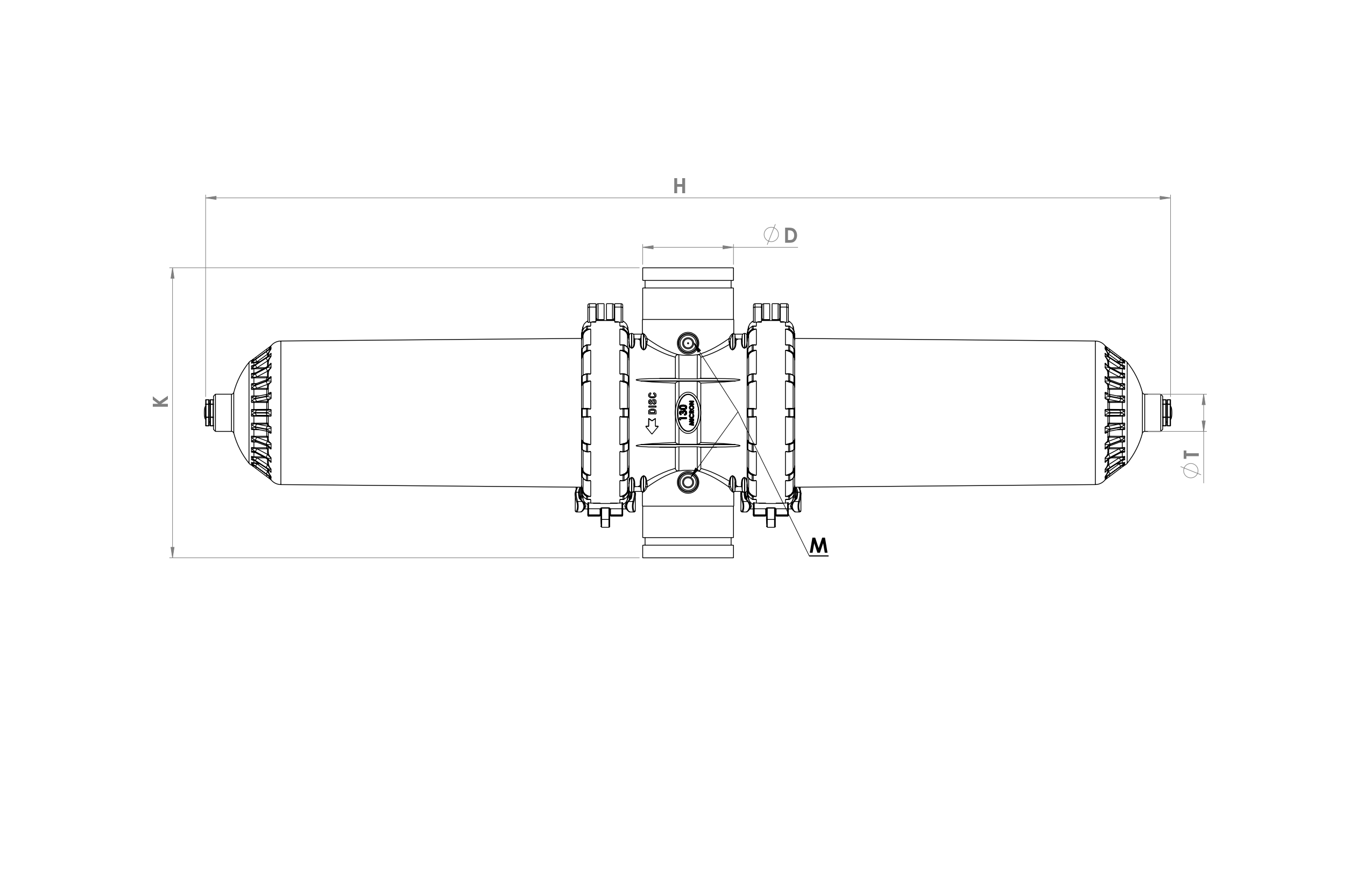

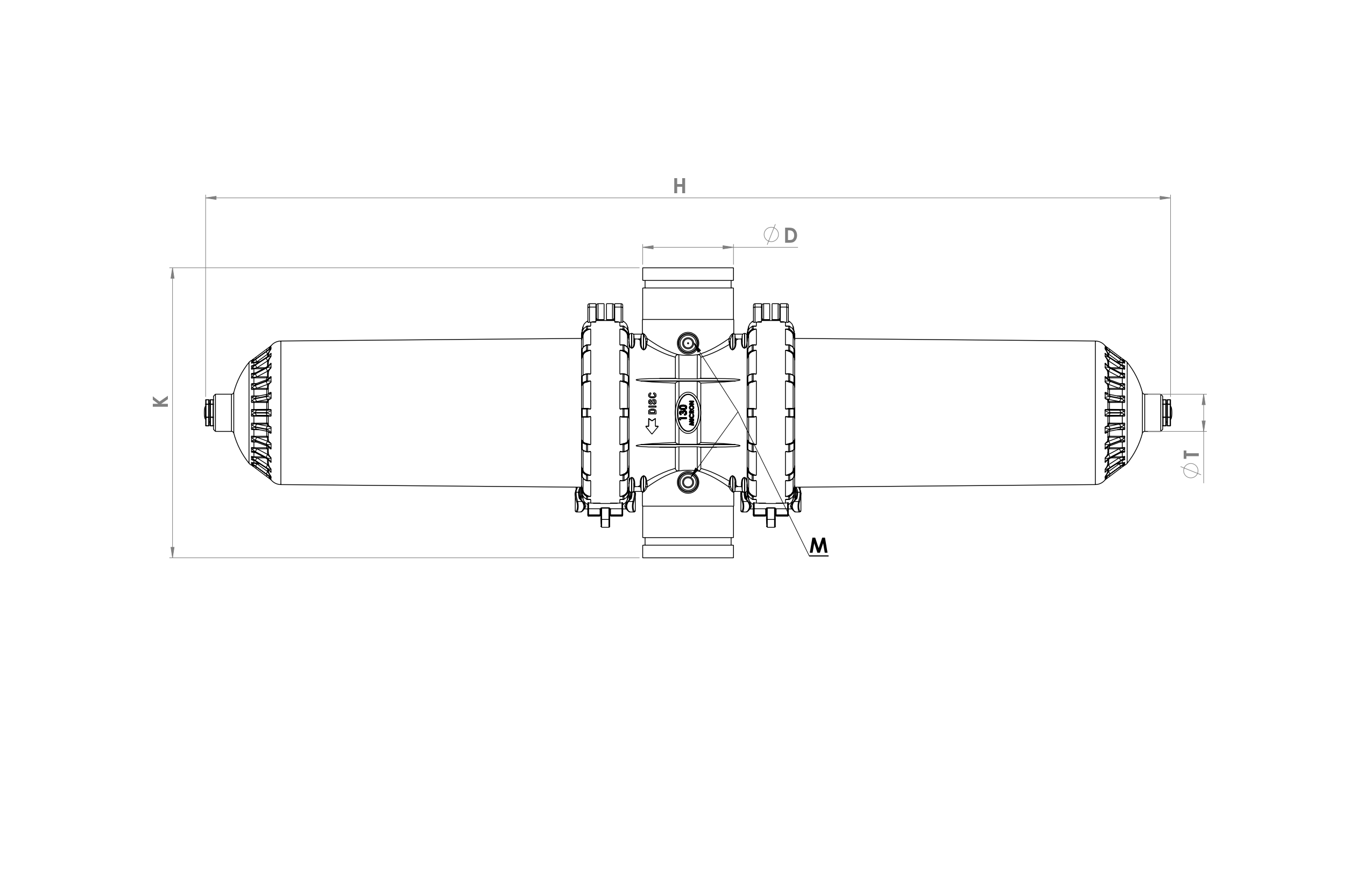

| CODE | D | M | T | D1 | H | K | Flow Rate | Filtration Area | Weight | ||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Inch | DN | Inch | Inch | mm | mm | mm | m³/h | GPM(US) | cm² | kg | |

| DE3 | 3 | 80 | 1/4 | 3/4 | 190 | 977 | 365 | 50 | 220 | 2280 | 8,4 |

| DE4 | 4 | 100 | 1/4 | 3/4 | 190 | 977 | 365 | 70 | 308 | 2280 | 8,6 |

| DES3 | 3 | 80 | 1/4 | 3/4 | 190 | 1216 | 365 | 60 | 264 | 3040 | 9,8 |

| DES4 | 4 | 100 | 1/4 | 3/4 | 190 | 1216 | 365 | 80 | 352 | 3040 | 10 |

| DE6 | 6 | 150 | 1/4 | 2 | 242 | 1658 | 462 | 180 | 792 | 5532 | 21 |

Send us a message

Fill out the form below to contact us.

Ürün Detayı

DD Series - Plastic Manual Double Disc Filters

GENERAL FEATURES

Cleaning Process

The pressure differential is manually monitored via the inlet and outlet manometers. An increase in pressure indicates the need for cleaning. To begin, shut off the water supply and depressurize the system. Then, remove the cover and extract the filter cartridge. The cartridge’s retaining screw must be loosened to separate the discs for a thorough cleaning with pressurized water. After cleaning, the filter is reassembled and ready for service.

Working Principle

Water enters the filter and passes through the filtration element (a set of discs). During operation, contaminants gradually accumulate on the surface of this element—the outer surface for discs. This buildup obstructs the water flow, creating a pressure differential between the filter’s inlet and outlet. Manual cleaning is required when this pressure differential reaches 0.7 bar

ADVANTAGES

Powerful Filtration, Smarter Design.

Double the Capacity. Uncompromised Reliability.

The Aytok DD Series manual disc filters are engineered with legendary durability to meet the highest operational demands. Their smart dual-body design doubles the filtration surface, enabling significantly higher flow rates while drastically reducing cleaning frequency, even under challenging water conditions. Manufactured with a robust polyamide body, the DD Series is designed to deliver reliable disc filtration performance with excellent resistance to pressure fluctuations and varying water quality. This advanced and versatile design guarantees years of trouble-free operation, providing superior reliability for your most demanding applications.

DÖKÜMANLAR

| CODE | D | M | T | D1 | H | K | Flow Rate | Filtration Area | Weight | ||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Inch | DN | Inch | Inch | mm | mm | mm | m³/h | GPM(US) | cm² | kg | |

| DE3 | 3 | 80 | 1/4 | 3/4 | 190 | 977 | 365 | 50 | 220 | 2280 | 8,4 |

| DE4 | 4 | 100 | 1/4 | 3/4 | 190 | 977 | 365 | 70 | 308 | 2280 | 8,6 |

| DES3 | 3 | 80 | 1/4 | 3/4 | 190 | 1216 | 365 | 60 | 264 | 3040 | 9,8 |

| DES4 | 4 | 100 | 1/4 | 3/4 | 190 | 1216 | 365 | 80 | 352 | 3040 | 10 |

| DE6 | 6 | 150 | 1/4 | 2 | 242 | 1658 | 462 | 180 | 792 | 5532 | 21 |