| Body Material | PA6GFR30 |

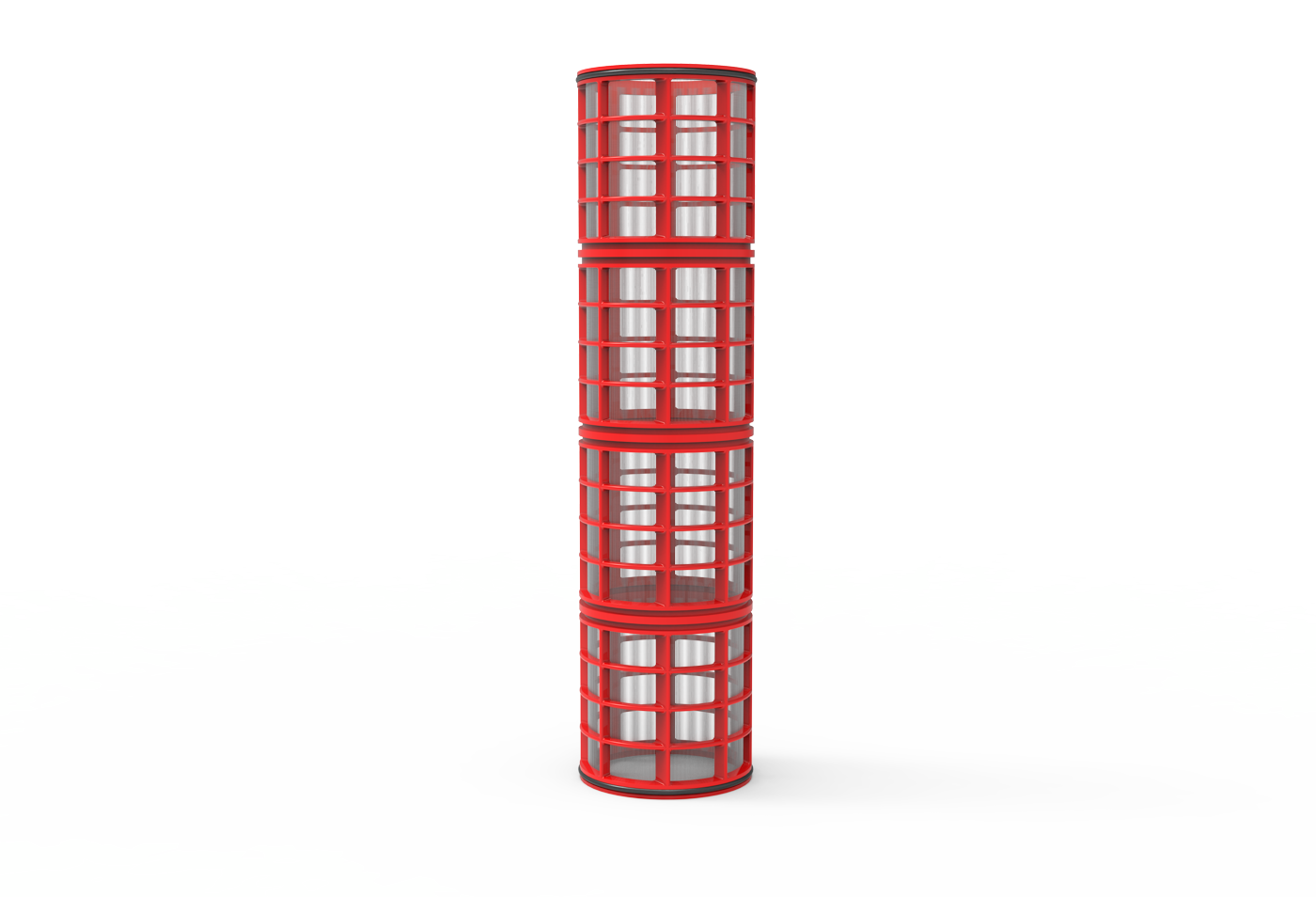

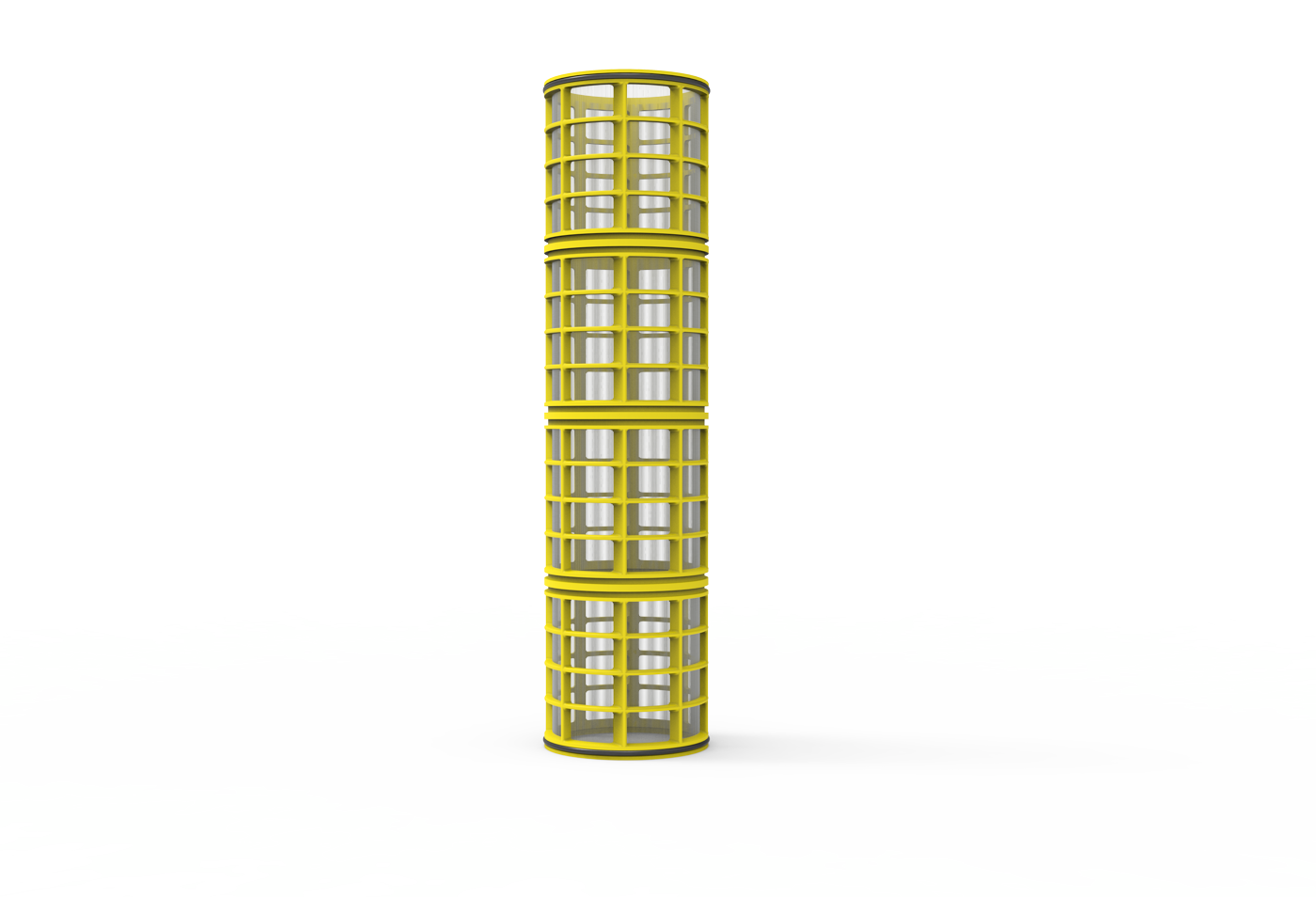

| Cartridge Material | SS304L, PA6GFR30 |

| Maximum Working Pressure | 8 bar ; 116 Psi |

| Minimum Working Pressure | 2 bar ; 29 Psi |

| Maximum Working Temperature | 60 °C ; 140°F |

| Back Washing Time | Time and Pressure Difference Setup |

| Control System | Electronic (AC/DC) |

| Filtration Sensitivity | 20-2000 μ (micron) |

Ürünlerimiz

water_drop Irrigation

Uygulama Alanları

water_drop IRRIGATION

Filter Types

Media Center

Send us a message

Fill out the form below to contact us.

Cleaning Process

The backwash sequence is triggered by either a preset pressure differential or a time interval. Upon activation, the control unit opens the discharge valve. Exposing this valve to atmospheric pressure creates a significant pressure drop, inducing a powerful reverse flow. This reverse flow drives a hydraulic turbine, which rotates the cleaning collector as a piston moves it linearly. The collector’s nozzles generate a high-velocity suction, vacuuming accumulated debris from the inner screen and expelling it through the drainage pipe. This combined helical motion ensures a systematic and thorough cleaning of the entire screen surface. Once complete, the discharge valve closes and the collector returns to its home position, concluding the cycle. Crucially, the main filtration process continues uninterrupted throughout this self-cleaning process.

Working Principle

Water enters the filter and passes sequentially through a coarse and then a fine screen. As contaminants accumulate on the inner surface of the fine screen, a pressure differential is created between the inlet and outlet. A backwash cycle is automatically initiated based on one of two conditions: when this pressure differential reaches a predetermined setpoint, or after a preset time interval has elapsed, whichever occurs first.

P-HF Series - Plastic Self-Cleaning Screen Filters (Single Body)

GENERAL FEATURES

| Body Material | PA6GFR30 |

| Cartridge Material | SS304L, PA6GFR30 |

| Maximum Working Pressure | 8 bar ; 116 Psi |

| Minimum Working Pressure | 2 bar ; 29 Psi |

| Maximum Working Temperature | 60 °C ; 140°F |

| Back Washing Time | Time and Pressure Difference Setup |

| Control System | Electronic (AC/DC) |

| Filtration Sensitivity | 20-2000 μ (micron) |

ADVANTAGES

Cleaning Process

The backwash sequence is triggered by either a preset pressure differential or a time interval. Upon activation, the control unit opens the discharge valve. Exposing this valve to atmospheric pressure creates a significant pressure drop, inducing a powerful reverse flow. This reverse flow drives a hydraulic turbine, which rotates the cleaning collector as a piston moves it linearly. The collector’s nozzles generate a high-velocity suction, vacuuming accumulated debris from the inner screen and expelling it through the drainage pipe. This combined helical motion ensures a systematic and thorough cleaning of the entire screen surface. Once complete, the discharge valve closes and the collector returns to its home position, concluding the cycle. Crucially, the main filtration process continues uninterrupted throughout this self-cleaning process.

Working Principle

Water enters the filter and passes sequentially through a coarse and then a fine screen. As contaminants accumulate on the inner surface of the fine screen, a pressure differential is created between the inlet and outlet. A backwash cycle is automatically initiated based on one of two conditions: when this pressure differential reaches a predetermined setpoint, or after a preset time interval has elapsed, whichever occurs first.

P-HF Series - Plastic Self-Cleaning Screen Filters (Single Body)

ADVANTAGES

Smart. Automated. Unstoppable.

This is the new era of plastic filtration. Our Plastic Automatic Filter fuses intelligent, handsfree automation with a rugged, corrosion-proof body to deliver a constant flow of clean water, ensuring total system protection and long-term reliability.

GENERAL FEATURES

| Body Material | PA6GFR30 |

| Cartridge Material | SS304L, PA6GFR30 |

| Maximum Working Pressure | 8 bar ; 116 Psi |

| Minimum Working Pressure | 2 bar ; 29 Psi |

| Maximum Working Temperature | 60 °C ; 140°F |

| Back Washing Time | Time and Pressure Difference Setup |

| Control System | Electronic (AC/DC) |

| Filtration Sensitivity | 20-2000 μ (micron) |

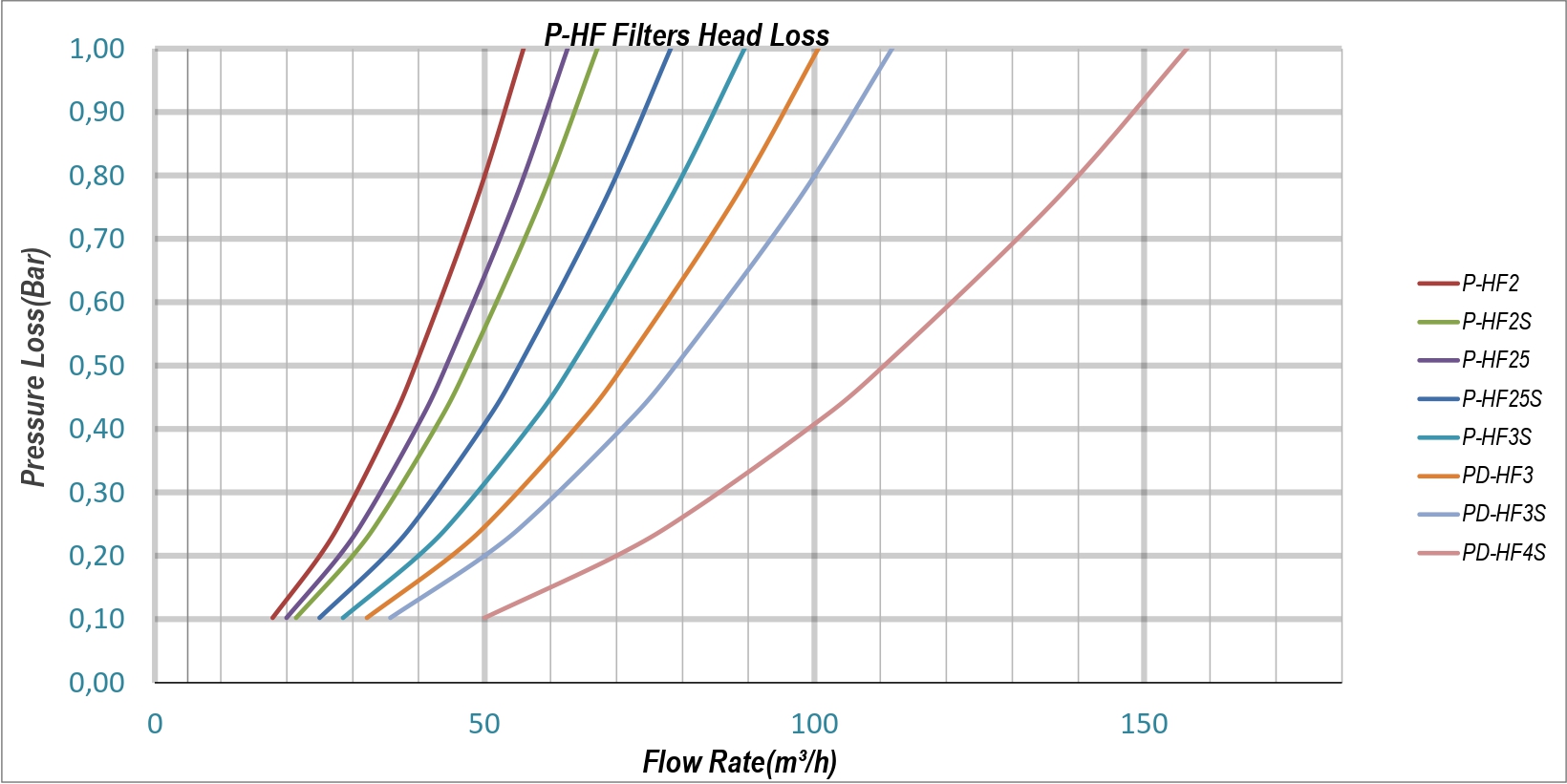

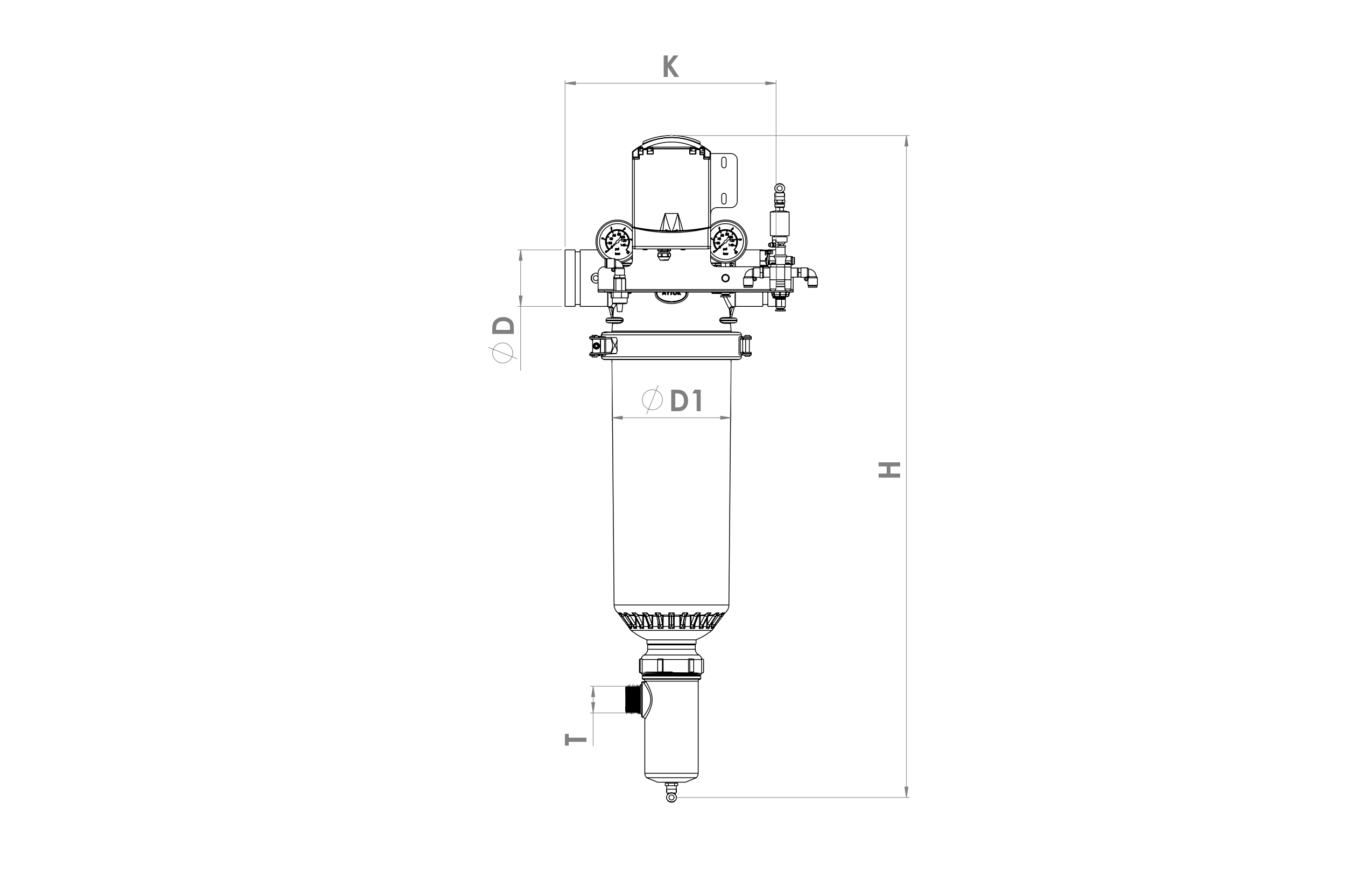

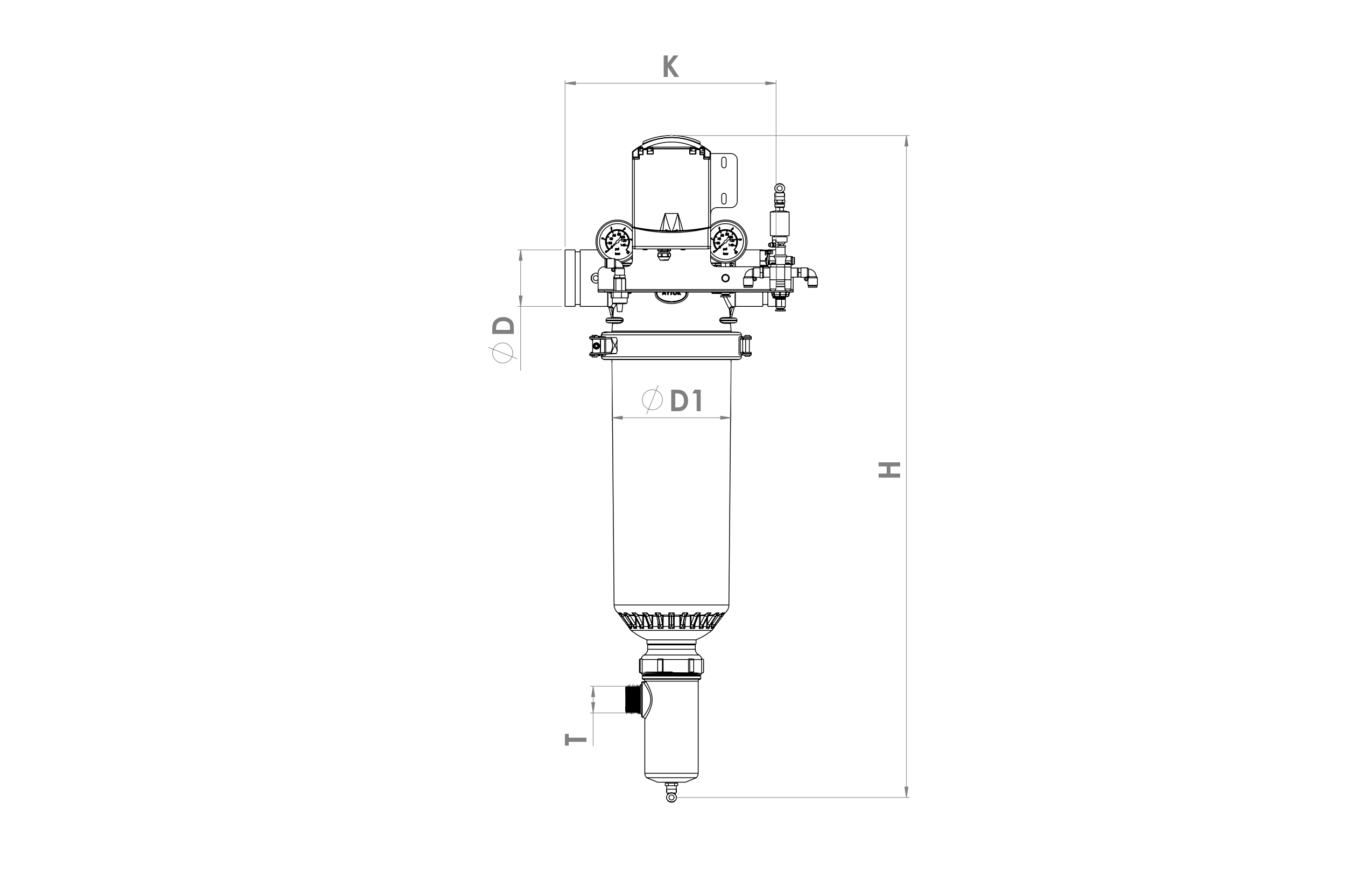

| CODE | Inlet/Outlet (D) | D1 | K | T | H | Drain Flow Rate | Main Flow Rate | Filtration Area cm² |

Nozzle Qty. |

Screen Qty. |

|||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Inch | DN | mm | mm | mm | mm | L/s | GPM(US) | m³/h | GPM(US) | ||||

| P-HF2 | 2 | 50 | 190 | 335 | 1,25 | 870 | 1,9 | 29 | 25 | 110 | 760 | 4 | 2 |

| P-HF2S | 2 | 50 | 190 | 335 | 1,25 | 990 | 2,8 | 44 | 30 | 132 | 1140 | 6 | 3 |

| P-HF25 | 2,5 | 65 | 190 | 335 | 1,25 | 870 | 1,9 | 29 | 28 | 123,2 | 760 | 4 | 2 |

| P-HF25S | 2,5 | 65 | 190 | 335 | 1,25 | 990 | 2,8 | 44 | 35 | 154 | 1140 | 6 | 3 |

| P-HF3S | 3 | 80 | 190 | 335 | 1,25 | 990 | 2,8 | 44 | 40 | 176 | 1140 | 6 | 3 |

Send us a message

Fill out the form below to contact us.

Ürün Detayı

P-HF Series - Plastic Self-Cleaning Screen Filters (Single Body)

GENERAL FEATURES

Cleaning Process

The backwash sequence is triggered by either a preset pressure differential or a time interval. Upon activation, the control unit opens the discharge valve. Exposing this valve to atmospheric pressure creates a significant pressure drop, inducing a powerful reverse flow. This reverse flow drives a hydraulic turbine, which rotates the cleaning collector as a piston moves it linearly. The collector’s nozzles generate a high-velocity suction, vacuuming accumulated debris from the inner screen and expelling it through the drainage pipe. This combined helical motion ensures a systematic and thorough cleaning of the entire screen surface. Once complete, the discharge valve closes and the collector returns to its home position, concluding the cycle. Crucially, the main filtration process continues uninterrupted throughout this self-cleaning process.

Working Principle

Water enters the filter and passes sequentially through a coarse and then a fine screen. As contaminants accumulate on the inner surface of the fine screen, a pressure differential is created between the inlet and outlet. A backwash cycle is automatically initiated based on one of two conditions: when this pressure differential reaches a predetermined setpoint, or after a preset time interval has elapsed, whichever occurs first.

ADVANTAGES

Powerful Filtration, Smarter Design.

Smart. Automated. Unstoppable.

This is the new era of plastic filtration. Our Plastic Automatic Filter fuses intelligent, handsfree automation with a rugged, corrosion-proof body to deliver a constant flow of clean water, ensuring total system protection and long-term reliability.

DÖKÜMANLAR

| CODE | Inlet/Outlet (D) | D1 | K | T | H | Drain Flow Rate | Main Flow Rate | Filtration Area cm² |

Nozzle Qty. |

Screen Qty. |

|||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Inch | DN | mm | mm | mm | mm | L/s | GPM(US) | m³/h | GPM(US) | ||||

| P-HF2 | 2 | 50 | 190 | 335 | 1,25 | 870 | 1,9 | 29 | 25 | 110 | 760 | 4 | 2 |

| P-HF2S | 2 | 50 | 190 | 335 | 1,25 | 990 | 2,8 | 44 | 30 | 132 | 1140 | 6 | 3 |

| P-HF25 | 2,5 | 65 | 190 | 335 | 1,25 | 870 | 1,9 | 29 | 28 | 123,2 | 760 | 4 | 2 |

| P-HF25S | 2,5 | 65 | 190 | 335 | 1,25 | 990 | 2,8 | 44 | 35 | 154 | 1140 | 6 | 3 |

| P-HF3S | 3 | 80 | 190 | 335 | 1,25 | 990 | 2,8 | 44 | 40 | 176 | 1140 | 6 | 3 |