| Body Material | S235JR |

| Cartridge Material | PP |

| Maximum Working Pressure | 8 bar ; 116 Psi |

| Maximum Working Temperature | 60 °C ; 140°F |

| Filtration Sensitivity | 20, 50, 100, 130, 200 μ (micron) |

| Painting Method | Electrostatic Powder Coating |

| Paint Coating Material | Epoxy-Polyester |

Ürünlerimiz

water_drop Irrigation

Uygulama Alanları

water_drop IRRIGATION

Filter Types

Media Center

Send us a message

Fill out the form below to contact us.

Cleaning Process

Manual cleaning is required when the pressure differential, monitored by manometers, indicates that the filter is clogged. The process begins by shutting down the system and depressurizing the filter. The cover is then removed and the disc cartridge is extracted. The key to the cleaning principle is loosening the cartridge’s compression screw, which separates the discs and exposes their entire surface area. This allows pressurized water to effectively flush away all accumulated contaminants. After cleaning, the cartridge is re-compressed, reinstalled, and the filter is returned to service.

Working Principle

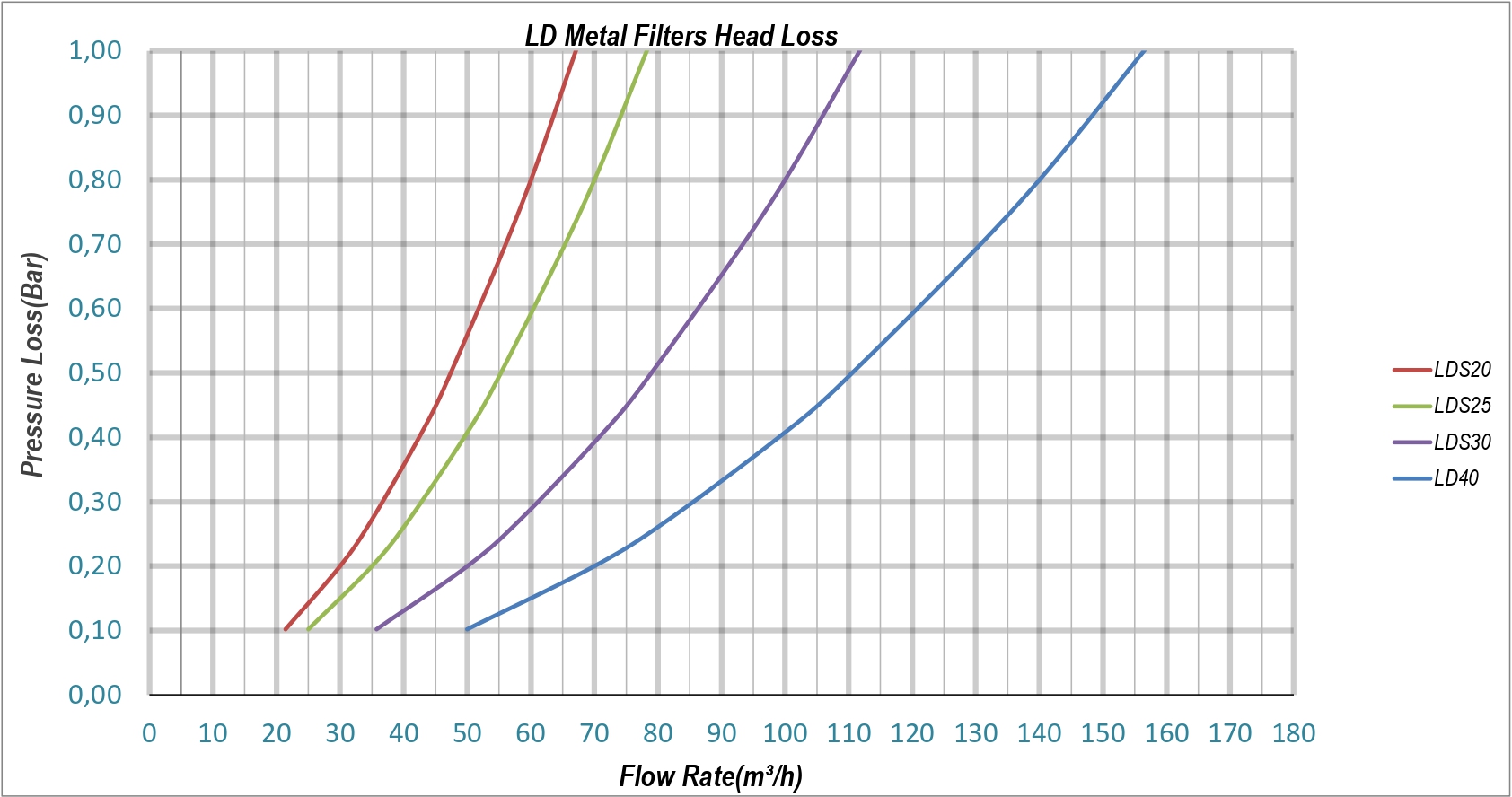

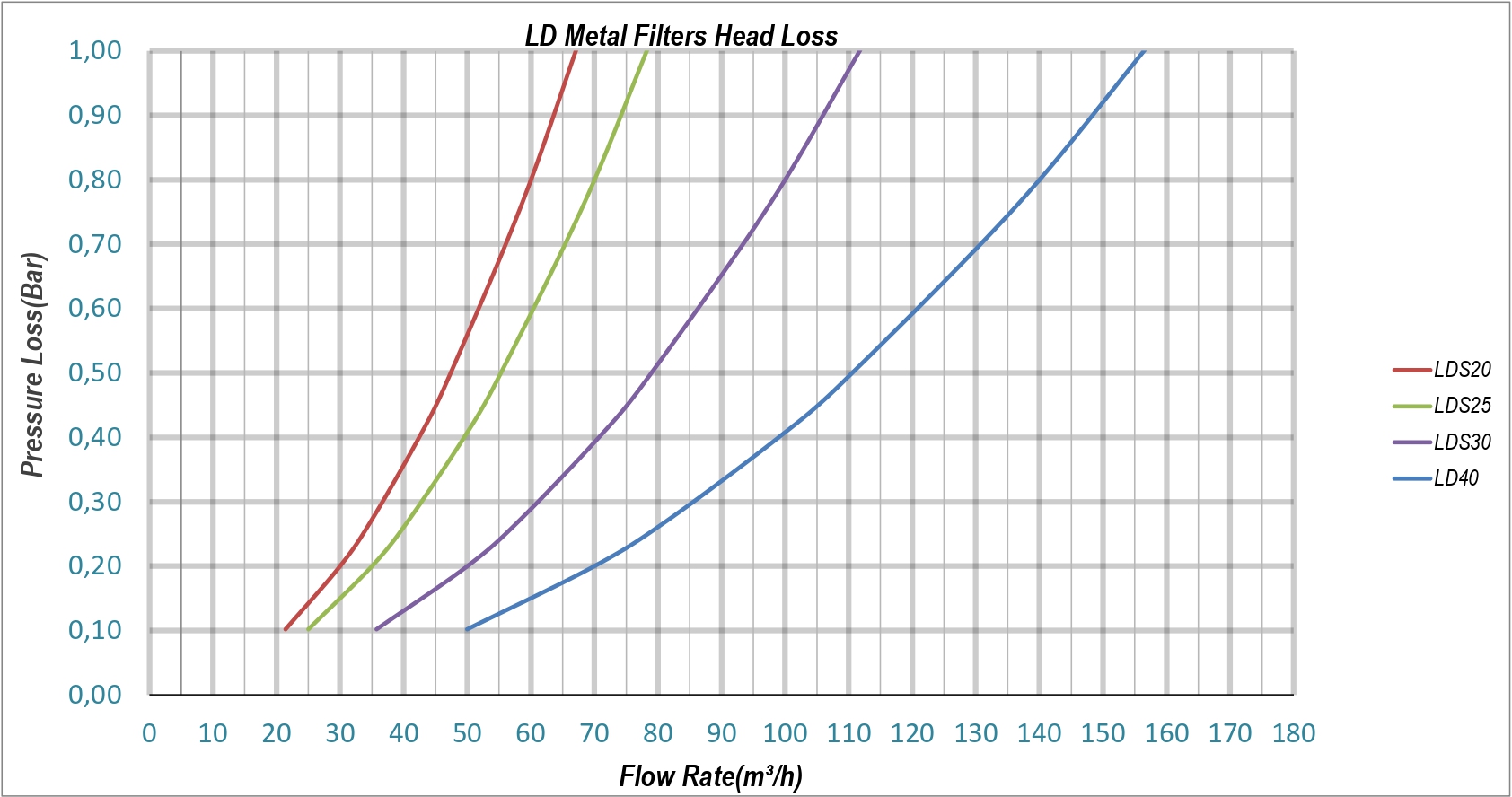

Water enters the filter and passes through a stack of discs. As it flows toward the outlet, contaminants gradually accumu - late on the outer surface of these discs. This buildup creates a pressure difference between the inlet and outlet. To ensure proper performance, the filter must be cleaned by the time the pressure difference reaches 0.7 bar.

LD Series - Vertical Metal Disc Filters

GENERAL FEATURES

| Body Material | S235JR |

| Cartridge Material | PP |

| Maximum Working Pressure | 8 bar ; 116 Psi |

| Maximum Working Temperature | 60 °C ; 140°F |

| Filtration Sensitivity | 20, 50, 100, 130, 200 μ (micron) |

| Painting Method | Electrostatic Powder Coating |

| Paint Coating Material | Epoxy-Polyester |

ADVANTAGES

Cleaning Process

Manual cleaning is required when the pressure differential, monitored by manometers, indicates that the filter is clogged. The process begins by shutting down the system and depressurizing the filter. The cover is then removed and the disc cartridge is extracted. The key to the cleaning principle is loosening the cartridge’s compression screw, which separates the discs and exposes their entire surface area. This allows pressurized water to effectively flush away all accumulated contaminants. After cleaning, the cartridge is re-compressed, reinstalled, and the filter is returned to service.

Working Principle

Water enters the filter and passes through a stack of discs. As it flows toward the outlet, contaminants gradually accumu - late on the outer surface of these discs. This buildup creates a pressure difference between the inlet and outlet. To ensure proper performance, the filter must be cleaned by the time the pressure difference reaches 0.7 bar.

LD Series - Vertical Metal Disc Filters

ADVANTAGES

Reliable Filtration, Ingeniously Engineered.

Our Manual Disc Filter delivers exceptionally consistent performance through a brilliantly simple, motor-free design. It intelligently harnesses the inherent pressure of your liquid flow for effective filtration, ensuring zero energy consumption and minimal maintenance. Customizable with a range of materials, including high-grade stainless steel for industrial challenges, it’s the smart choice for sustainable, long-term reliability.

GENERAL FEATURES

| Body Material | S235JR |

| Cartridge Material | PP |

| Maximum Working Pressure | 8 bar ; 116 Psi |

| Maximum Working Temperature | 60 °C ; 140°F |

| Filtration Sensitivity | 20, 50, 100, 130, 200 μ (micron) |

| Painting Method | Electrostatic Powder Coating |

| Paint Coating Material | Epoxy-Polyester |

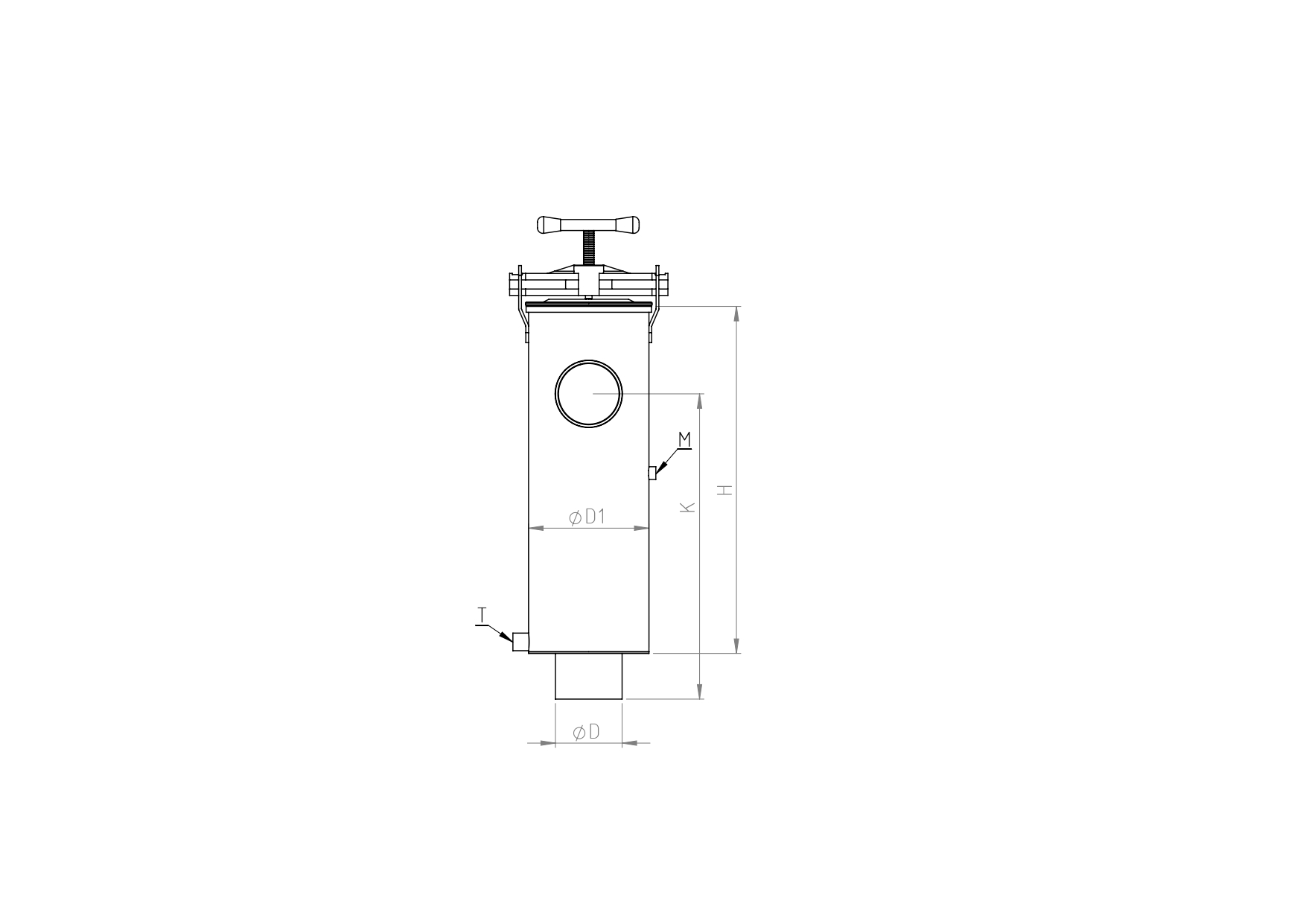

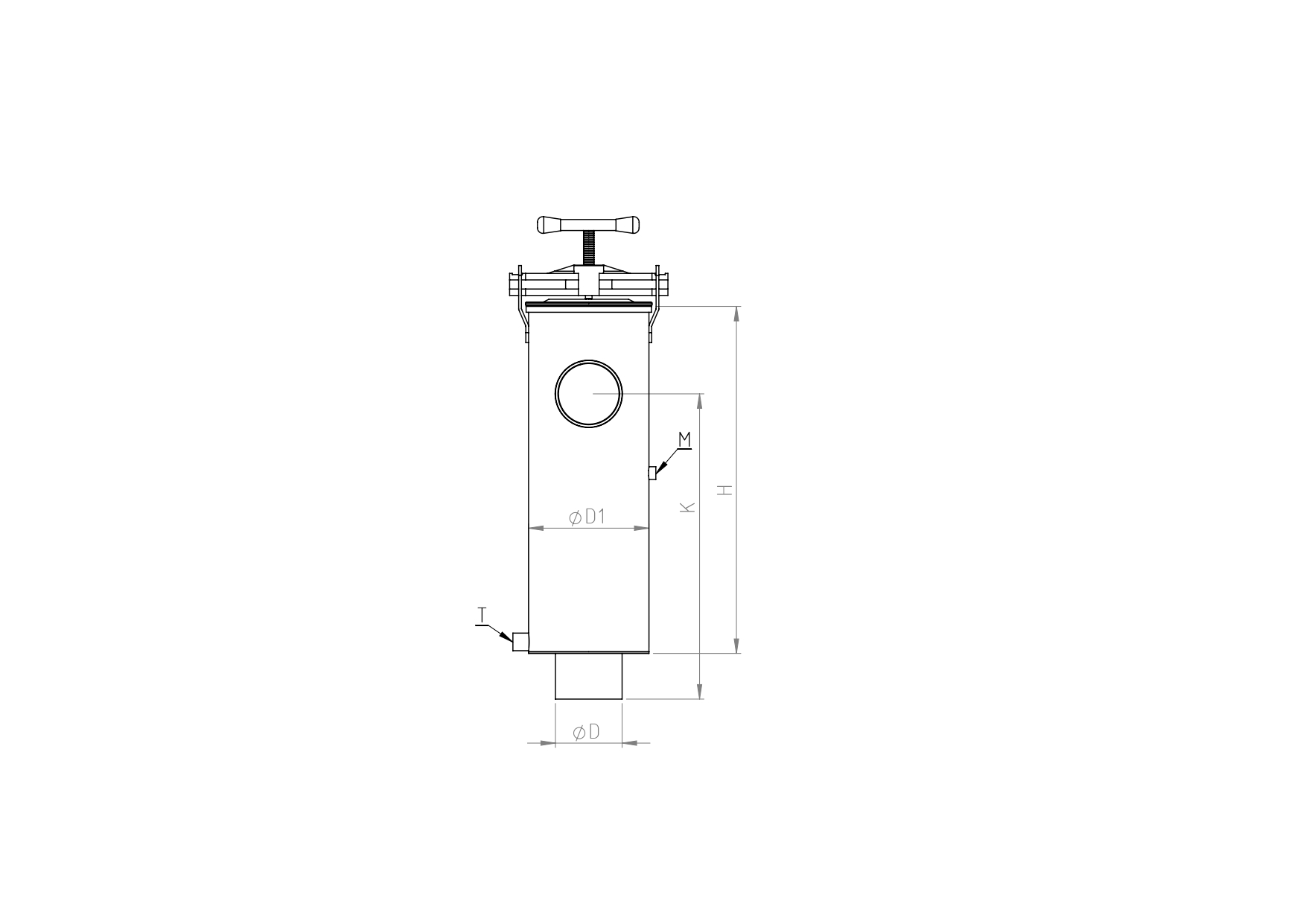

| Code | D | D1 | M | T | K | H | Flow Rate | Weight (kg) |

|

|---|---|---|---|---|---|---|---|---|---|

| İnç | (mm) | m³/h | GPM(US) | ||||||

| LDS20 | 2 | 6 | 1/4 | 1/2 | 320 | 400 | 30 | 132 | 15 |

| LDS25 | 2 1/2 | 8 | 1/4 | 3/4 | 320 | 400 | 35 | 154 | 19 |

| LDS30 | 3 | 8 | 1/4 | 3/4 | 455 | 515 | 50 | 220 | 22 |

| LD40 | 4 | 8 | 1/4 | 3/4 | 555 | 625 | 70 | 308 | 27 |

Send us a message

Fill out the form below to contact us.

Ürün Detayı

LD Series - Vertical Metal Disc Filters

GENERAL FEATURES

Cleaning Process

Manual cleaning is required when the pressure differential, monitored by manometers, indicates that the filter is clogged. The process begins by shutting down the system and depressurizing the filter. The cover is then removed and the disc cartridge is extracted. The key to the cleaning principle is loosening the cartridge’s compression screw, which separates the discs and exposes their entire surface area. This allows pressurized water to effectively flush away all accumulated contaminants. After cleaning, the cartridge is re-compressed, reinstalled, and the filter is returned to service.

Working Principle

Water enters the filter and passes through a stack of discs. As it flows toward the outlet, contaminants gradually accumu - late on the outer surface of these discs. This buildup creates a pressure difference between the inlet and outlet. To ensure proper performance, the filter must be cleaned by the time the pressure difference reaches 0.7 bar.

ADVANTAGES

Powerful Filtration, Smarter Design.

Reliable Filtration, Ingeniously Engineered.

Our Manual Disc Filter delivers exceptionally consistent performance through a brilliantly simple, motor-free design. It intelligently harnesses the inherent pressure of your liquid flow for effective filtration, ensuring zero energy consumption and minimal maintenance. Customizable with a range of materials, including high-grade stainless steel for industrial challenges, it’s the smart choice for sustainable, long-term reliability.

DÖKÜMANLAR

| Code | D | D1 | M | T | K | H | Flow Rate | Weight (kg) |

|

|---|---|---|---|---|---|---|---|---|---|

| İnç | (mm) | m³/h | GPM(US) | ||||||

| LDS20 | 2 | 6 | 1/4 | 1/2 | 320 | 400 | 30 | 132 | 15 |

| LDS25 | 2 1/2 | 8 | 1/4 | 3/4 | 320 | 400 | 35 | 154 | 19 |

| LDS30 | 3 | 8 | 1/4 | 3/4 | 455 | 515 | 50 | 220 | 22 |

| LD40 | 4 | 8 | 1/4 | 3/4 | 555 | 625 | 70 | 308 | 27 |