MPE

| Body Material | PP |

| Cartridge Material | SS304L, PP |

| Maximum Working Pressure | 8 bar ; 116 Psi |

| Maximum Working Temperature | 60 °C ; 140°F |

| Filtration Sensitivity | 80, 100, 130, 200 μ (micron) |

Searching...

Try different keywords

Fill out the form below to contact us.

The pressure differential is manually monitored via the inlet and outlet manometers. An increase in pressure indicates the need for cleaning. To begin, shut off the water supply and depressurize the system. Then, remove the cover and extract the filter cartridge.

The cartridge's retaining screw must be loosened to separate the discs for a thorough cleaning with pressurized water. After cleaning, the filter is reassembled and ready for service.

Water enters the filter and passes through the filtration element (a fine screen). During operation, contaminants gradually accumulate on the surface of this element—the inner surface for screens. This buildup obstructs the water flow, creating a pressure differential between the filter’s inlet and outlet. Manual cleaning is required when this pressure differential reaches 0.7 bar.

| Body Material | PP |

| Cartridge Material | SS304L, PP |

| Maximum Working Pressure | 8 bar ; 116 Psi |

| Maximum Working Temperature | 60 °C ; 140°F |

| Filtration Sensitivity | 80, 100, 130, 200 μ (micron) |

The pressure differential is manually monitored via the inlet and outlet manometers. An increase in pressure indicates the need for cleaning. To begin, shut off the water supply and depressurize the system. Then, remove the cover and extract the filter cartridge.

The cartridge's retaining screw must be loosened to separate the discs for a thorough cleaning with pressurized water. After cleaning, the filter is reassembled and ready for service.

Water enters the filter and passes through the filtration element (a fine screen). During operation, contaminants gradually accumulate on the surface of this element—the inner surface for screens. This buildup obstructs the water flow, creating a pressure differential between the filter’s inlet and outlet. Manual cleaning is required when this pressure differential reaches 0.7 bar.

Designed for efficiency in tight spaces, Aytok MPE filters provide a robust and versatile solution for low-flow water systems. They are perfectly suited for applications like garden irrigation, fertigation, and protecting small-scale cooling equipment.

| Body Material | PP |

| Cartridge Material | SS304L, PP |

| Maximum Working Pressure | 8 bar ; 116 Psi |

| Maximum Working Temperature | 60 °C ; 140°F |

| Filtration Sensitivity | 80, 100, 130, 200 μ (micron) |

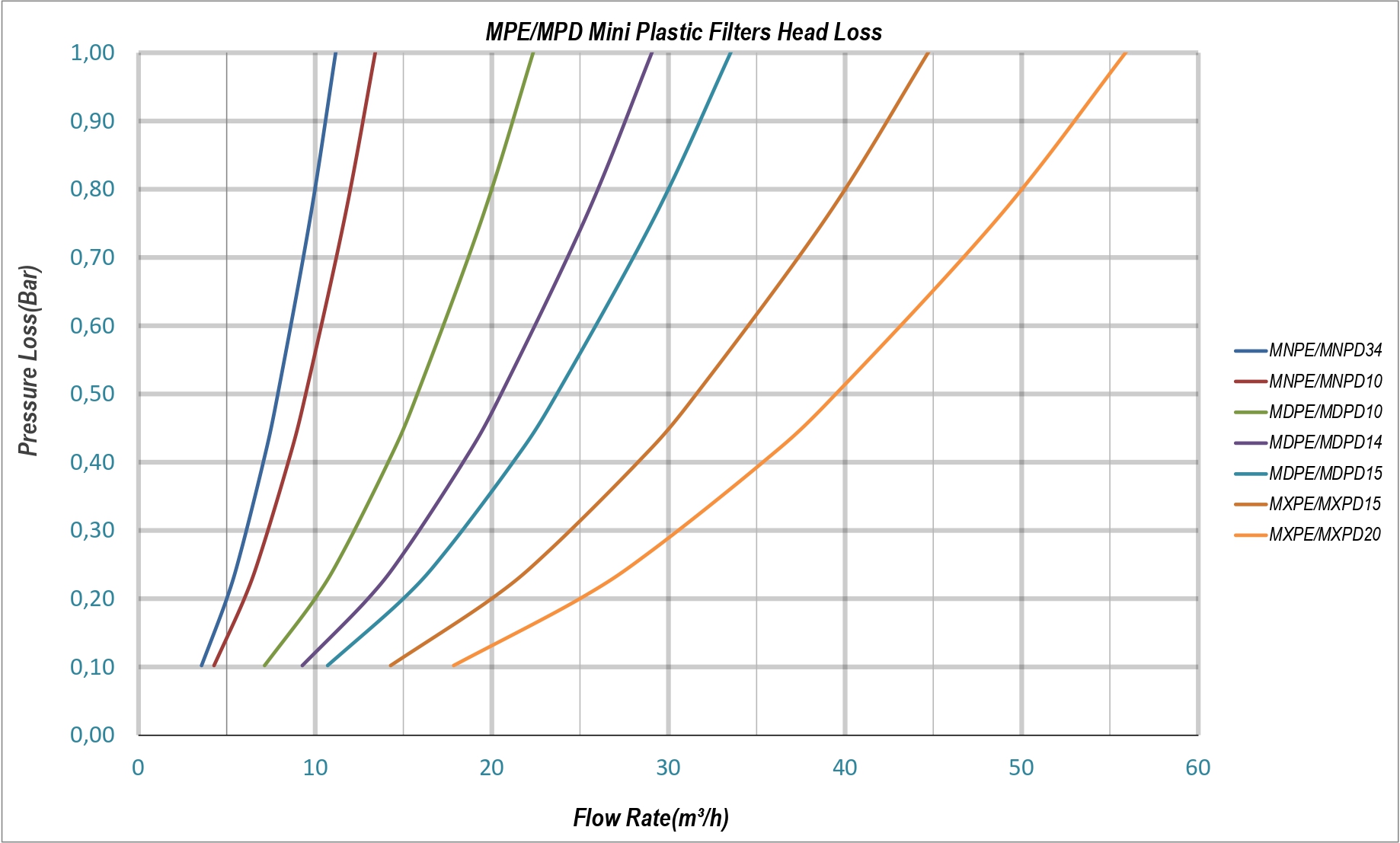

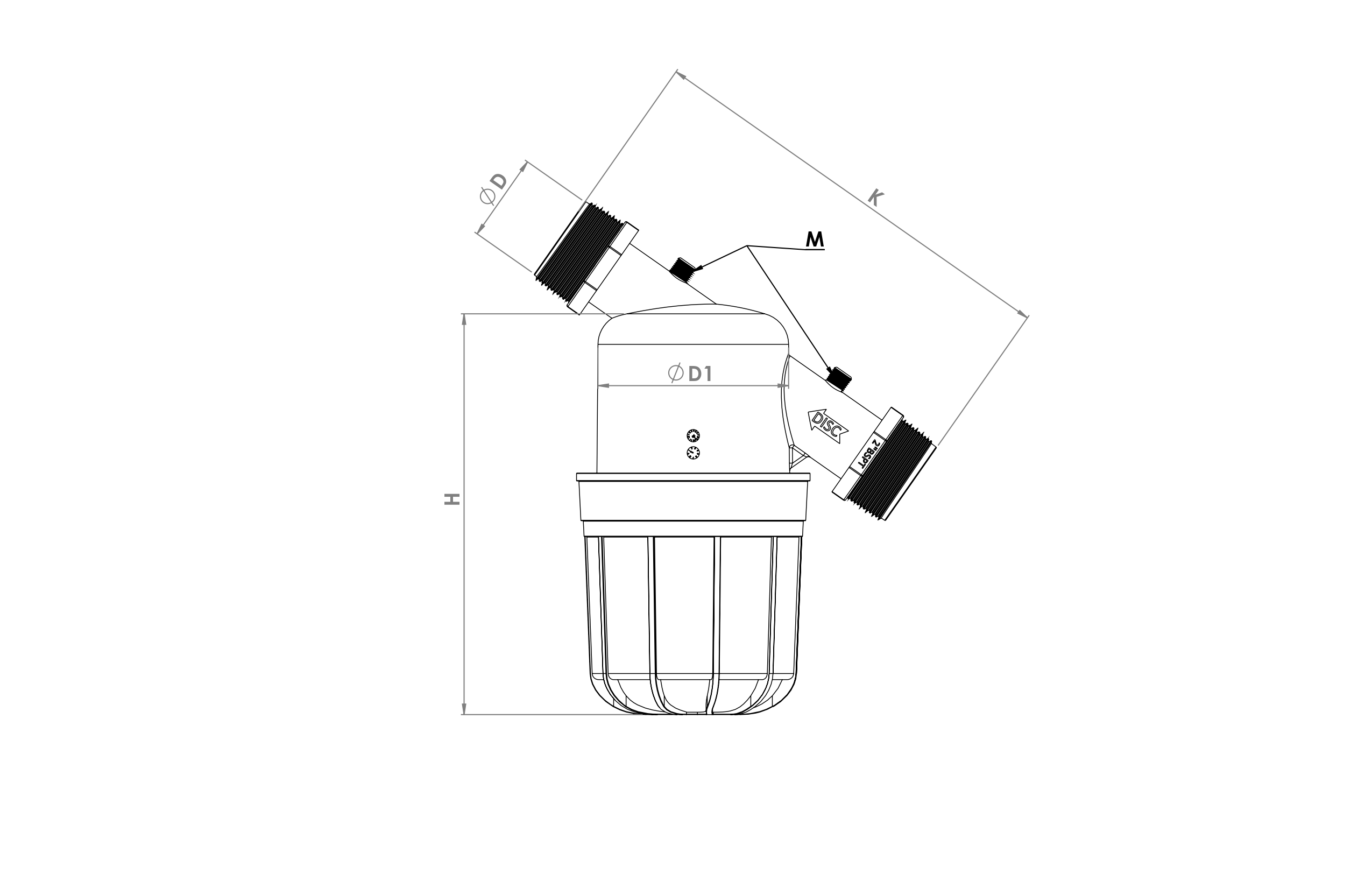

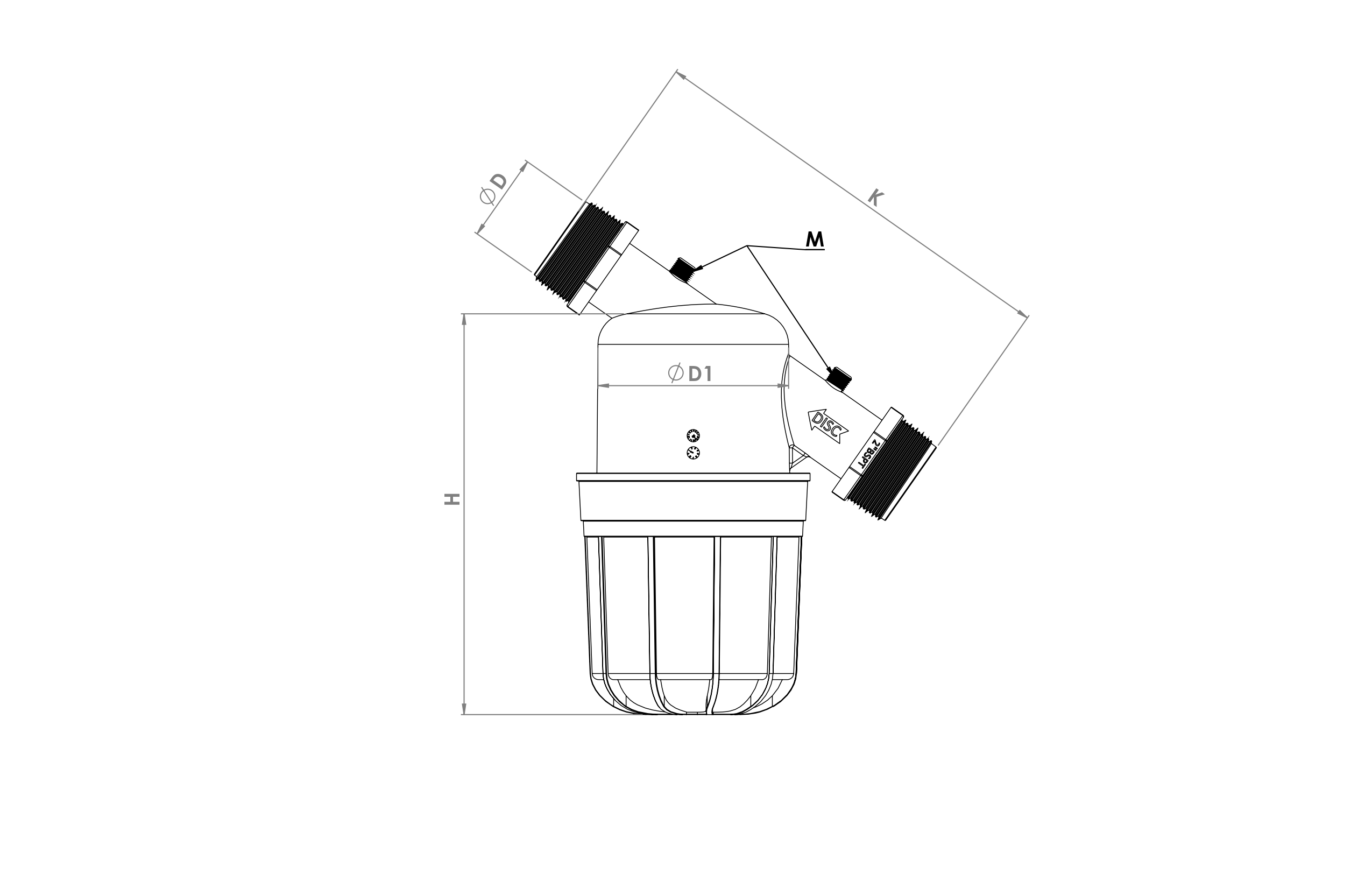

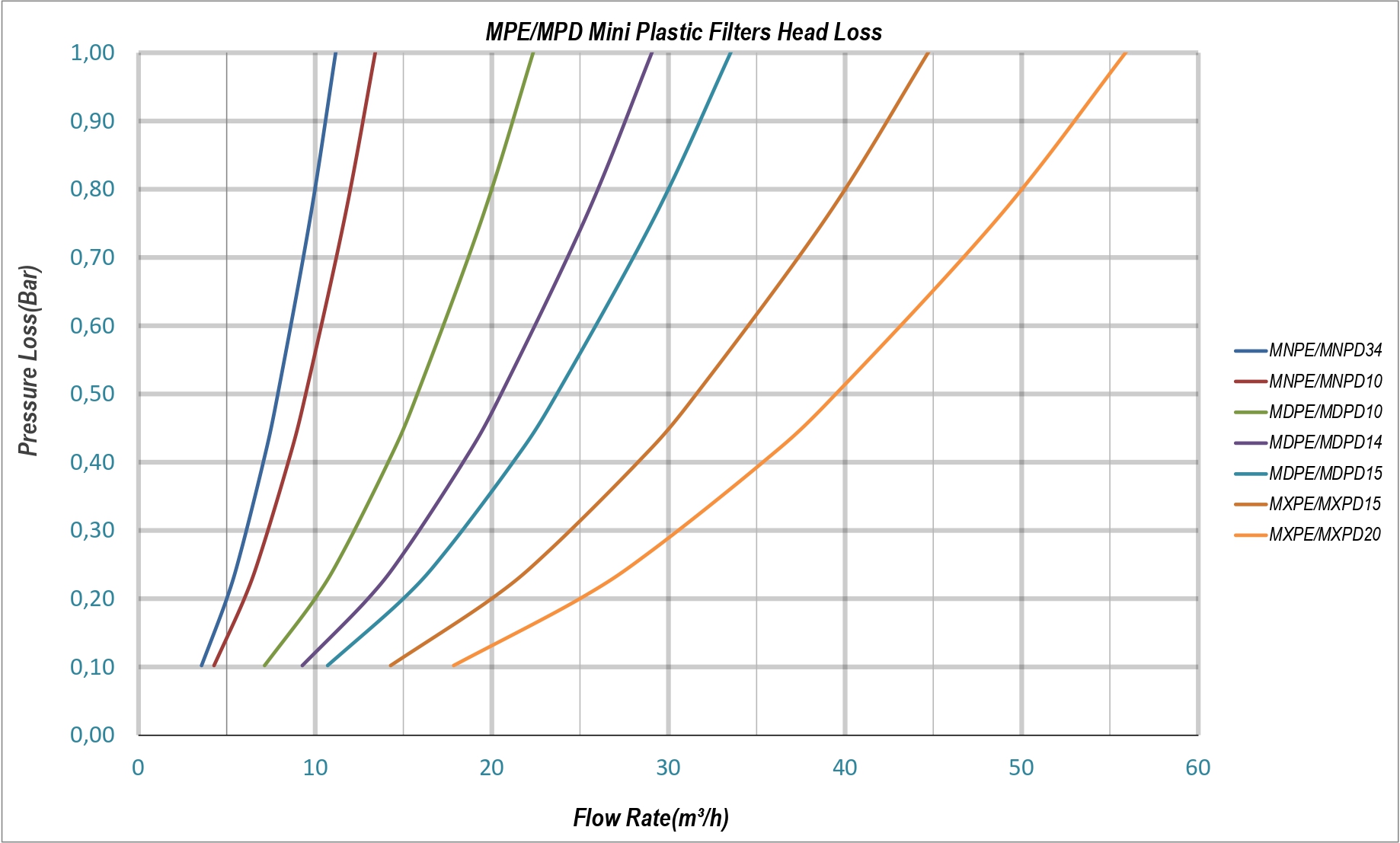

| CODE | D | M | T | D1 | H | K | Flow Rate | Filtration Area cm² |

Weight kg |

||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Inch | DN | Inch | Inch | mm | mm | mm | m³/h | GPM(US) | |||

| MNPE34 | 3/4 | 20 | - | 3/4 | 68 | 190 | 160 | 5 | 22 | 165 | 0,3 |

| MNPE10 | 1 | 25 | - | 3/4 | 68 | 190 | 160 | 6 | 26,4 | 165 | 0,3 |

| MDPE10 | 1 | 25 | - | 3/4 | 96 | 230 | 220 | 10 | 44 | 300 | 0,75 |

| MDPE14 | 1 1/4 | 32 | - | 3/4 | 96 | 230 | 220 | 13 | 66 | 300 | 0,75 |

| MDPE15 | 1 1/2 | 40 | - | 3/4 | 96 | 230 | 220 | 15 | 66 | 300 | 0,75 |

| MXPE15 | 1 1/2 | 40 | 1/4 | 3/4 | 120 | 280 | 270 | 20 | 88 | 515 | 1,2 |

| MXPE20 | 2 | 50 | 1/4 | 3/4 | 120 | 280 | 270 | 25 | 110 | 515 | 1,2 |

Fill out the form below to contact us.

| Body Material | PP |

| Cartridge Material | SS304L, PP |

| Maximum Working Pressure | 8 bar ; 116 Psi |

| Maximum Working Temperature | 60 °C ; 140°F |

| Filtration Sensitivity | 80, 100, 130, 200 μ (micron) |

The pressure differential is manually monitored via the inlet and outlet manometers. An increase in pressure indicates the need for cleaning. To begin, shut off the water supply and depressurize the system. Then, remove the cover and extract the filter cartridge.

The cartridge's retaining screw must be loosened to separate the discs for a thorough cleaning with pressurized water. After cleaning, the filter is reassembled and ready for service.

Water enters the filter and passes through the filtration element (a fine screen). During operation, contaminants gradually accumulate on the surface of this element—the inner surface for screens. This buildup obstructs the water flow, creating a pressure differential between the filter’s inlet and outlet. Manual cleaning is required when this pressure differential reaches 0.7 bar.

Designed for efficiency in tight spaces, Aytok MPE filters provide a robust and versatile solution for low-flow water systems. They are perfectly suited for applications like garden irrigation, fertigation, and protecting small-scale cooling equipment.

| CODE | D | M | T | D1 | H | K | Flow Rate | Filtration Area cm² |

Weight kg |

||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Inch | DN | Inch | Inch | mm | mm | mm | m³/h | GPM(US) | |||

| MNPE34 | 3/4 | 20 | - | 3/4 | 68 | 190 | 160 | 5 | 22 | 165 | 0,3 |

| MNPE10 | 1 | 25 | - | 3/4 | 68 | 190 | 160 | 6 | 26,4 | 165 | 0,3 |

| MDPE10 | 1 | 25 | - | 3/4 | 96 | 230 | 220 | 10 | 44 | 300 | 0,75 |

| MDPE14 | 1 1/4 | 32 | - | 3/4 | 96 | 230 | 220 | 13 | 66 | 300 | 0,75 |

| MDPE15 | 1 1/2 | 40 | - | 3/4 | 96 | 230 | 220 | 15 | 66 | 300 | 0,75 |

| MXPE15 | 1 1/2 | 40 | 1/4 | 3/4 | 120 | 280 | 270 | 20 | 88 | 515 | 1,2 |

| MXPE20 | 2 | 50 | 1/4 | 3/4 | 120 | 280 | 270 | 25 | 110 | 515 | 1,2 |