| Body Material | S235JR |

| Maximum Working Pressure | 8 bar ; 116 Psi |

| Maximum Working Temperature | 60 °C ; 140°F |

| Painting Method | Electrostatic Powder Coating |

| Paint Coating Material | Epoxy-Polyester |

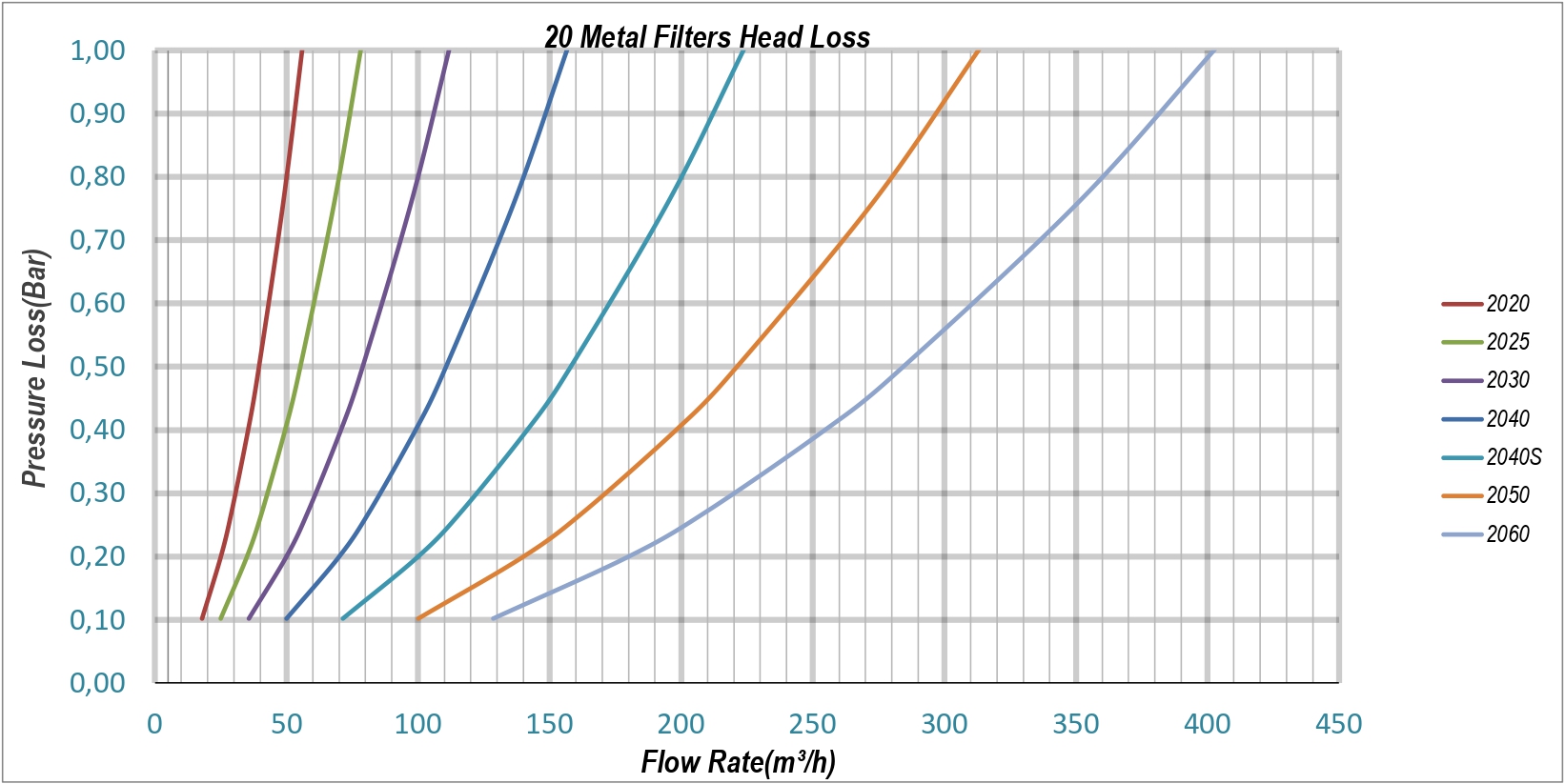

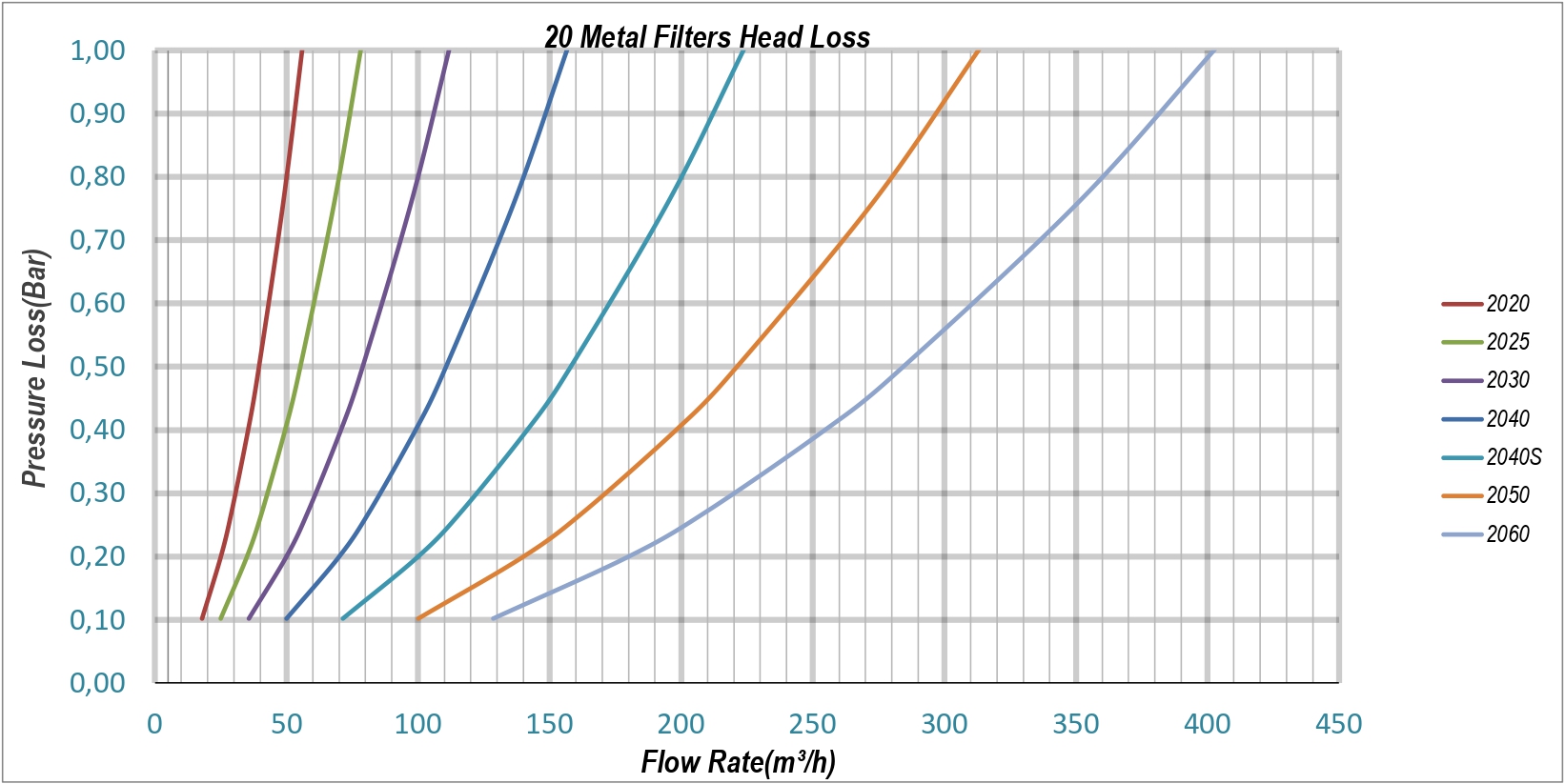

| Minimum Flow Rate | 2020: 20 m³/h 2025: 30 m³/h 2030: 40 m³/h 2040: 50 m³/h 2040S: 75 m³/h 2050: 100 m³/h 2060: 150 m³/h |

Ürünlerimiz

water_drop Irrigation

Uygulama Alanları

water_drop IRRIGATION

Filter Types

Media Center

Send us a message

Fill out the form below to contact us.

Cleaning Process

During filtration, solid particles accumulate in the collection tank at the bottom. This tank is periodically purged through a discharge valve. The valve’s operation can be either manual, requiring user intervention, or fully automatic, triggered by a controller.

Working Principle

Hydrocyclone filters separate suspended solids from liquids using the principle of centrifugal force, with no moving parts or filter media. When the water mixture enters the hydrocyclone's conical body at a high-speed, tangential angle, it creates a powerful swirling vortex. This rapid rotation throws heavier particles like sand and silt to the outer wall, where they spiral down to be collected in a separation tank at the bottom. Meanwhile, the cleaner, lighter water is drawn up through the center of the vortex and exits through the top outlet, ready for use.

20 Series - Metal Hydrocyclone Filters

GENERAL FEATURES

| Body Material | S235JR |

| Maximum Working Pressure | 8 bar ; 116 Psi |

| Maximum Working Temperature | 60 °C ; 140°F |

| Painting Method | Electrostatic Powder Coating |

| Paint Coating Material | Epoxy-Polyester |

| Minimum Flow Rate | 2020: 20 m³/h 2025: 30 m³/h 2030: 40 m³/h 2040: 50 m³/h 2040S: 75 m³/h 2050: 100 m³/h 2060: 150 m³/h |

ADVANTAGES

Cleaning Process

During filtration, solid particles accumulate in the collection tank at the bottom. This tank is periodically purged through a discharge valve. The valve’s operation can be either manual, requiring user intervention, or fully automatic, triggered by a controller.

Working Principle

Hydrocyclone filters separate suspended solids from liquids using the principle of centrifugal force, with no moving parts or filter media. When the water mixture enters the hydrocyclone's conical body at a high-speed, tangential angle, it creates a powerful swirling vortex. This rapid rotation throws heavier particles like sand and silt to the outer wall, where they spiral down to be collected in a separation tank at the bottom. Meanwhile, the cleaner, lighter water is drawn up through the center of the vortex and exits through the top outlet, ready for use.

20 Series - Metal Hydrocyclone Filters

ADVANTAGES

Your Heavy-Duty Answer to Abrasive Sand.

The Aytok Metal Hydrocyclone uses pure centrifugal force to powerfully eject sand and heavy particles before they can erode your system. With no screens, no moving parts, and zero power needed, it’s the most effective way to protect your main filters and reduce maintenance. Its specially treated, reinforced metal body is engineered to withstand high pressures and demanding field conditions, delivering steadfast protection where it’s needed most.

GENERAL FEATURES

| Body Material | S235JR |

| Maximum Working Pressure | 8 bar ; 116 Psi |

| Maximum Working Temperature | 60 °C ; 140°F |

| Painting Method | Electrostatic Powder Coating |

| Paint Coating Material | Epoxy-Polyester |

| Minimum Flow Rate | 2020: 20 m³/h 2025: 30 m³/h 2030: 40 m³/h 2040: 50 m³/h 2040S: 75 m³/h 2050: 100 m³/h 2060: 150 m³/h |

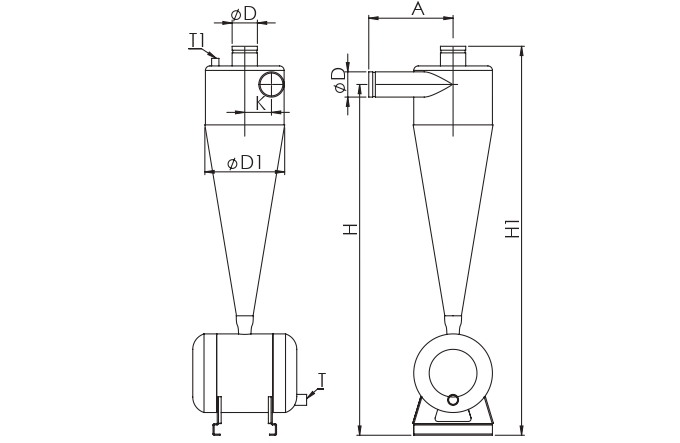

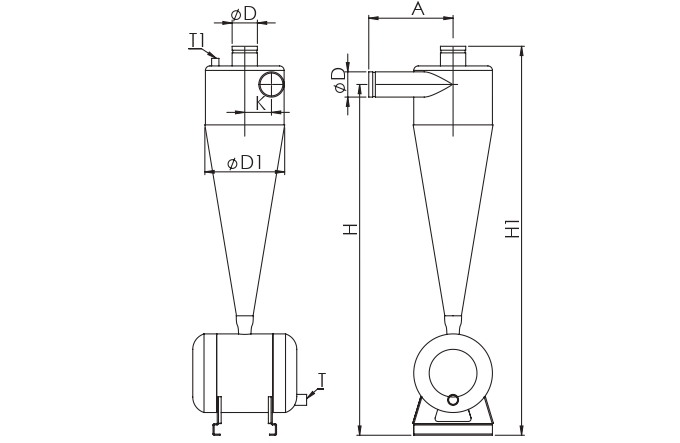

| CODE | D | D1 | T | T1 | K | A | H | H1 | Flow Rate | Weight (kg) |

|

|---|---|---|---|---|---|---|---|---|---|---|---|

| Inch | (mm) | m³/h | GPM(US) | ||||||||

| 2020 | 2 | 11 | 3/4 | 1/2 | 110 | 250 | 1185 | 1305 | 25 | 110 | 25 |

| 2025 | 2 1/2 | 11 | 1 | 1/2 | 102 | 300 | 1255 | 1385 | 35 | 154 | 27 |

| 2030 | 3 | 11 | 1 | 1/2 | 95 | 300 | 1250 | 1385 | 50 | 220 | 28 |

| 2040 | 4 | 11 | 1 | 1/2 | 82,5 | 300 | 1235 | 1385 | 70 | 308 | 30 |

| 2040S | 4 | 13 | 2 | 3/4 | 102,5 | 350 | 1280 | 1430 | 100 | 440 | 35 |

| 2050 | 5 | 15 | 2 | 1 | 120 | 400 | 1520 | 1745 | 120-140 | 528-616 | 65 |

| 2060 | 6 | 18 | 2 | 1 | 142,5 | 450 | 1750 | 2035 | 160-200 | 704-880 | 92 |

Send us a message

Fill out the form below to contact us.

Ürün Detayı

20 Series - Metal Hydrocyclone Filters

GENERAL FEATURES

Cleaning Process

During filtration, solid particles accumulate in the collection tank at the bottom. This tank is periodically purged through a discharge valve. The valve’s operation can be either manual, requiring user intervention, or fully automatic, triggered by a controller.

Working Principle

Hydrocyclone filters separate suspended solids from liquids using the principle of centrifugal force, with no moving parts or filter media. When the water mixture enters the hydrocyclone's conical body at a high-speed, tangential angle, it creates a powerful swirling vortex. This rapid rotation throws heavier particles like sand and silt to the outer wall, where they spiral down to be collected in a separation tank at the bottom. Meanwhile, the cleaner, lighter water is drawn up through the center of the vortex and exits through the top outlet, ready for use.

ADVANTAGES

Powerful Filtration, Smarter Design.

Your Heavy-Duty Answer to Abrasive Sand.

The Aytok Metal Hydrocyclone uses pure centrifugal force to powerfully eject sand and heavy particles before they can erode your system. With no screens, no moving parts, and zero power needed, it’s the most effective way to protect your main filters and reduce maintenance. Its specially treated, reinforced metal body is engineered to withstand high pressures and demanding field conditions, delivering steadfast protection where it’s needed most.

DÖKÜMANLAR

| CODE | D | D1 | T | T1 | K | A | H | H1 | Flow Rate | Weight (kg) |

|

|---|---|---|---|---|---|---|---|---|---|---|---|

| Inch | (mm) | m³/h | GPM(US) | ||||||||

| 2020 | 2 | 11 | 3/4 | 1/2 | 110 | 250 | 1185 | 1305 | 25 | 110 | 25 |

| 2025 | 2 1/2 | 11 | 1 | 1/2 | 102 | 300 | 1255 | 1385 | 35 | 154 | 27 |

| 2030 | 3 | 11 | 1 | 1/2 | 95 | 300 | 1250 | 1385 | 50 | 220 | 28 |

| 2040 | 4 | 11 | 1 | 1/2 | 82,5 | 300 | 1235 | 1385 | 70 | 308 | 30 |

| 2040S | 4 | 13 | 2 | 3/4 | 102,5 | 350 | 1280 | 1430 | 100 | 440 | 35 |

| 2050 | 5 | 15 | 2 | 1 | 120 | 400 | 1520 | 1745 | 120-140 | 528-616 | 65 |

| 2060 | 6 | 18 | 2 | 1 | 142,5 | 450 | 1750 | 2035 | 160-200 | 704-880 | 92 |