| Body Material | PA6GFR30 |

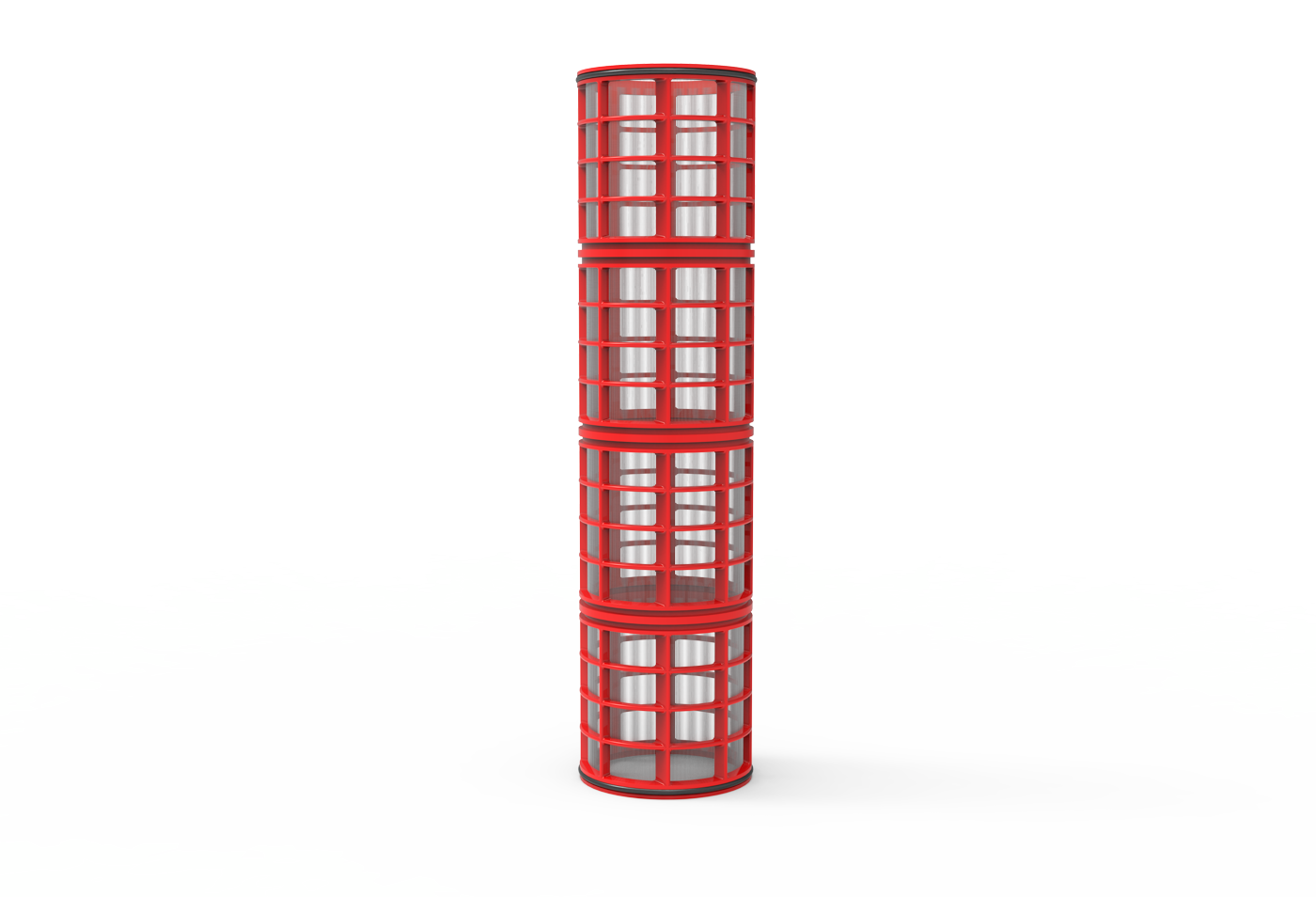

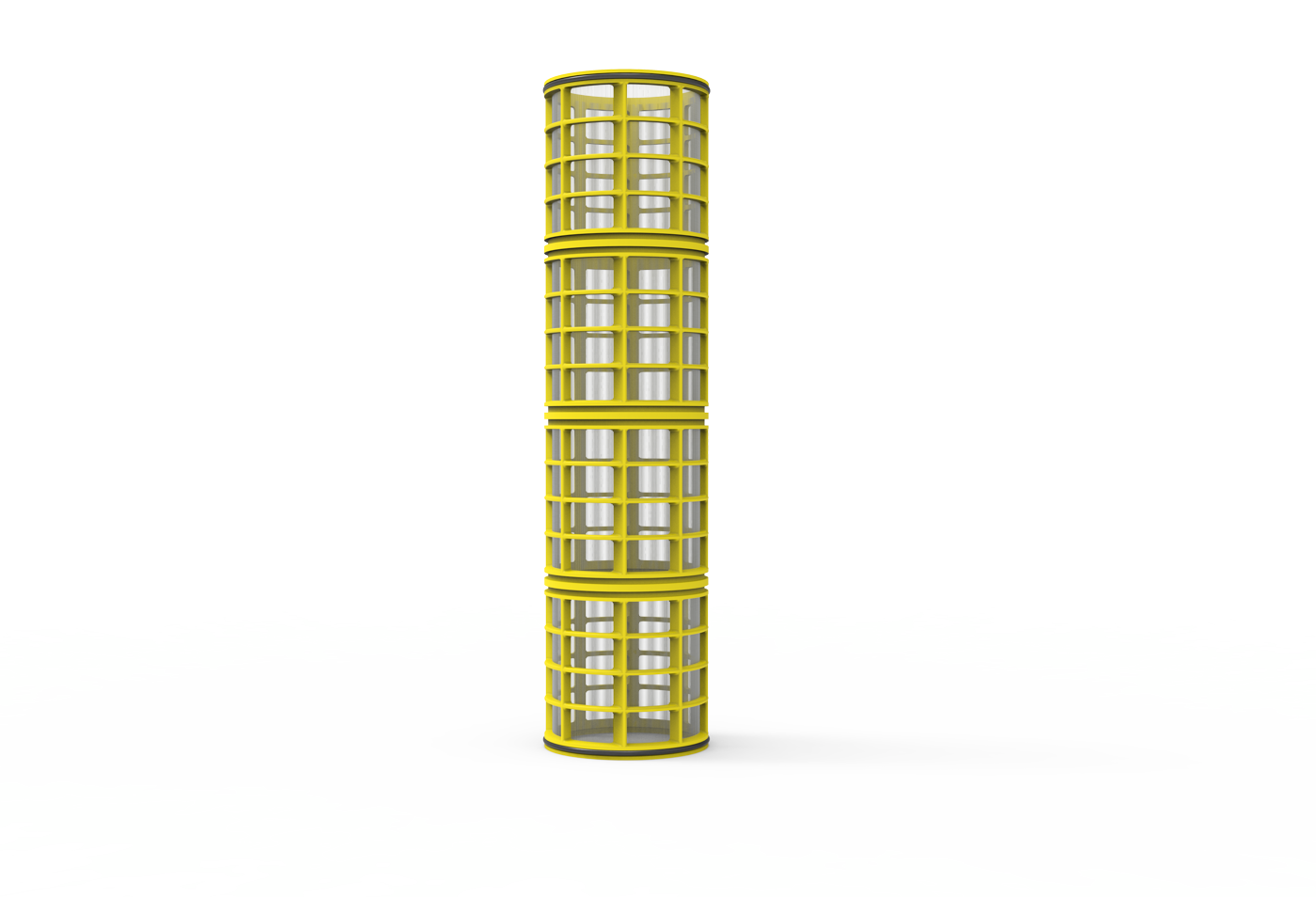

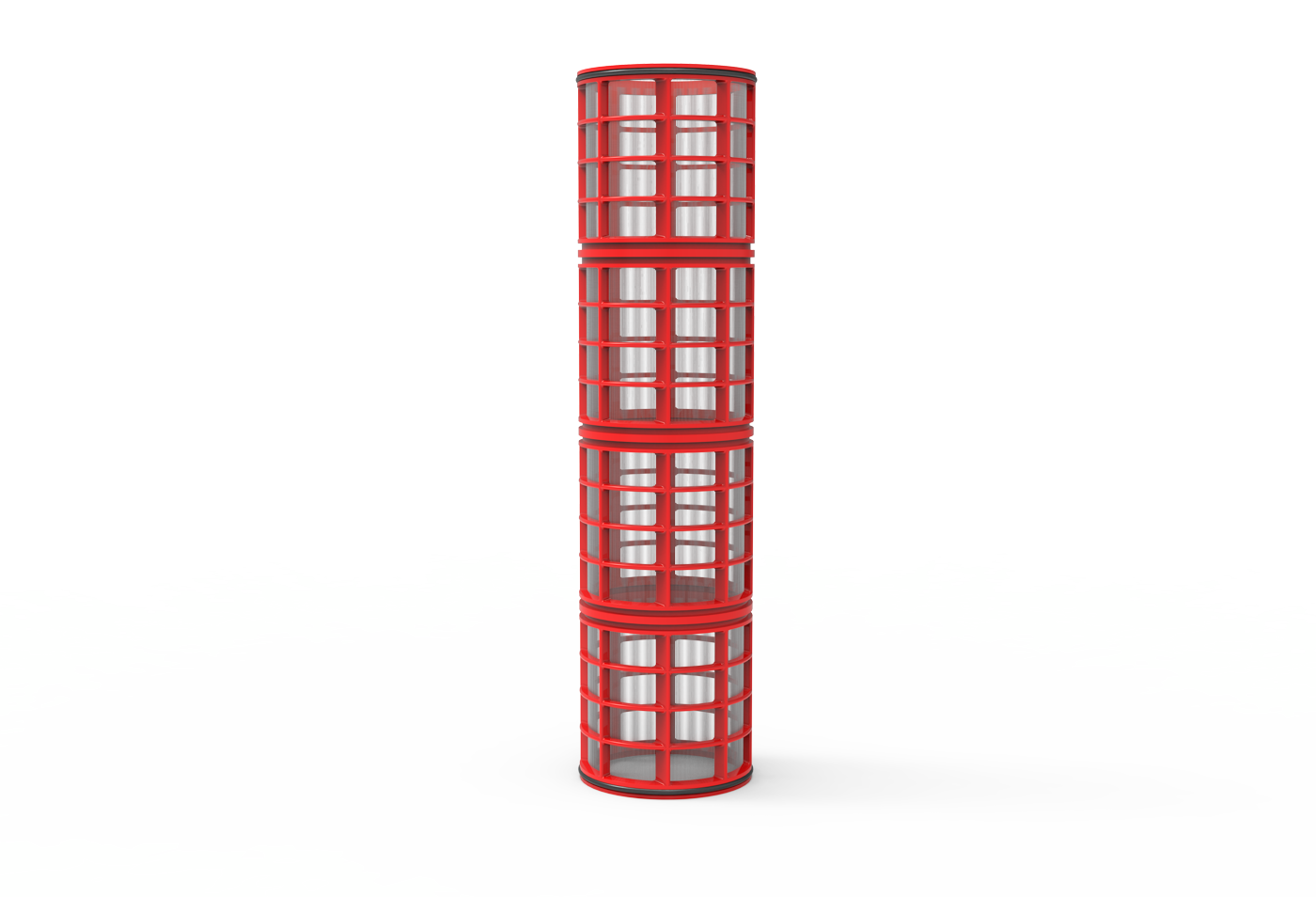

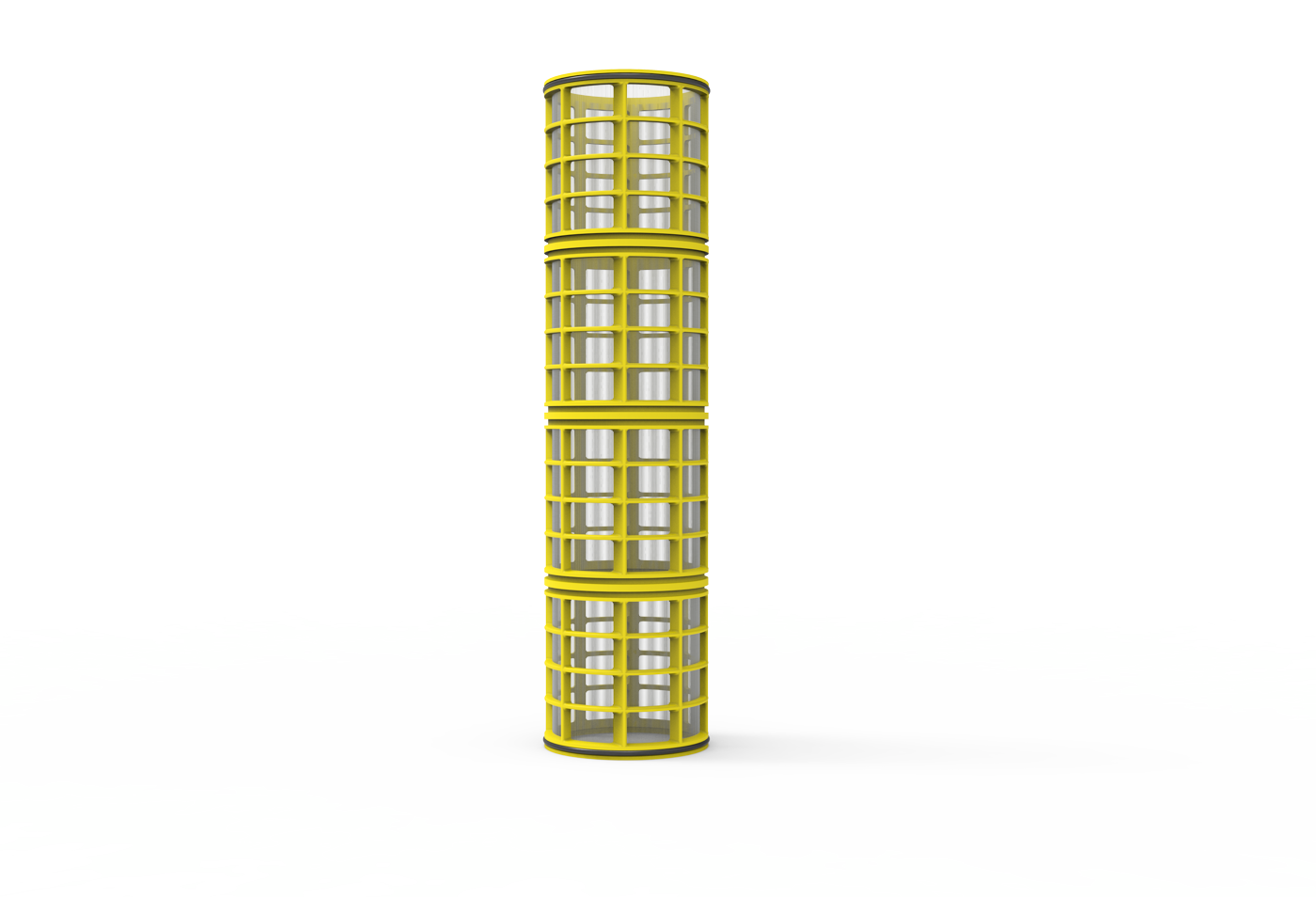

| Cartridge Material | SS304L, PA6GFR30 |

| Maximum Working Pressure | 8 bar ; 116 Psi |

| Minimum Working Pressure | 1 bar ; 14.5 Psi |

| Maximum Working Temperature | 60 °C ; 140°F |

| Control System | Semi Automatic Control |

| Filtration Sensitivity | 20-200 μ (micron) |

Ürünlerimiz

water_drop Irrigation

Uygulama Alanları

water_drop IRRIGATION

Filter Types

Media Center

Send us a message

Fill out the form below to contact us.

Cleaning Process

The manual flushing process is initiated by opening the filter’s flush valve and rotating the cleaning handle at a constant speed. This rotation moves a set of internal nozzles across the screen surface. The open valve creates a localized pressure drop, generating a high-velocity suction effect through the nozzles that vacuums contaminants off the screen and discharges them. The cleaning cycle consists of two passes: a primary pass as the handle is turned to its limit, and a secondary pass as it is rotated back to its home position. The process is completed by closing the flush valve.

Working Principle

Water enters the filter and passes through the fine screen element. During operation, contaminants gradually accumulate on the inner surface of the screen. This buildup restricts water flow, creating a pressure differential between the filter’s inlet and outlet. Manual cleaning is required when this pressure differential reaches 0.7 bar.

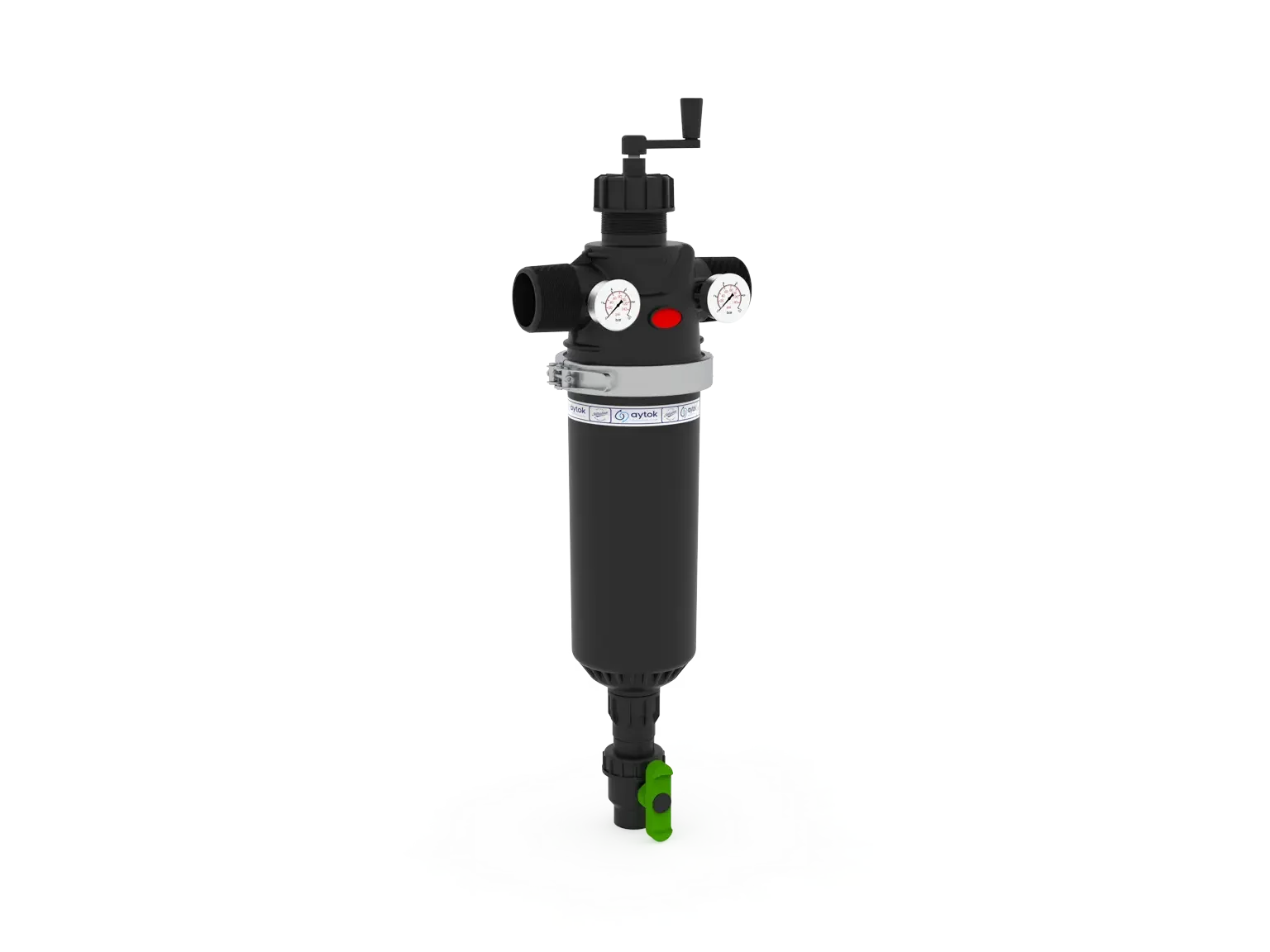

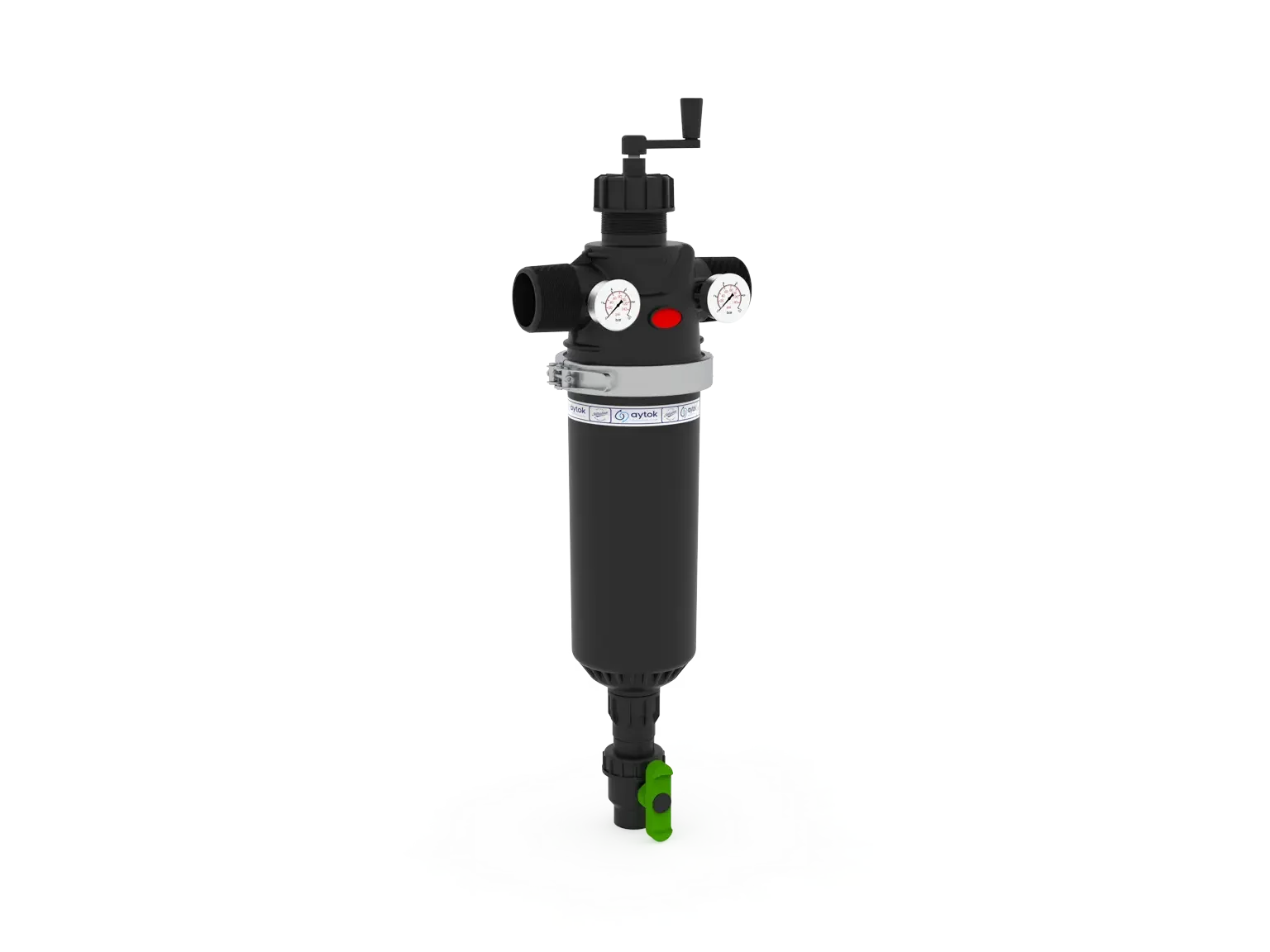

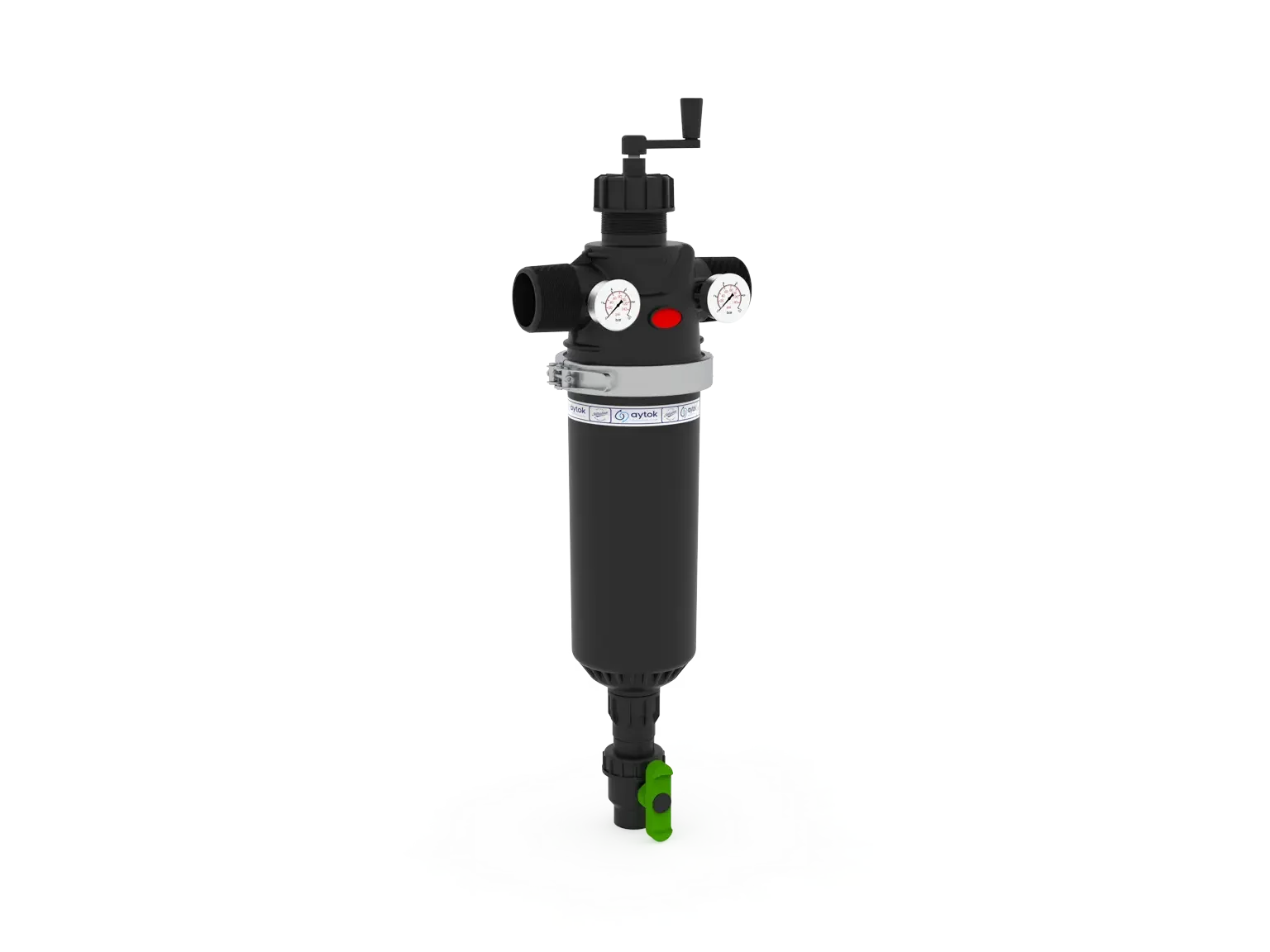

PV & PVS Series - Plastic Semi-Automatic Screen Filters (Single Body)

GENERAL FEATURES

| Body Material | PA6GFR30 |

| Cartridge Material | SS304L, PA6GFR30 |

| Maximum Working Pressure | 8 bar ; 116 Psi |

| Minimum Working Pressure | 1 bar ; 14.5 Psi |

| Maximum Working Temperature | 60 °C ; 140°F |

| Control System | Semi Automatic Control |

| Filtration Sensitivity | 20-200 μ (micron) |

ADVANTAGES

Cleaning Process

The manual flushing process is initiated by opening the filter’s flush valve and rotating the cleaning handle at a constant speed. This rotation moves a set of internal nozzles across the screen surface. The open valve creates a localized pressure drop, generating a high-velocity suction effect through the nozzles that vacuums contaminants off the screen and discharges them. The cleaning cycle consists of two passes: a primary pass as the handle is turned to its limit, and a secondary pass as it is rotated back to its home position. The process is completed by closing the flush valve.

Working Principle

Water enters the filter and passes through the fine screen element. During operation, contaminants gradually accumulate on the inner surface of the screen. This buildup restricts water flow, creating a pressure differential between the filter’s inlet and outlet. Manual cleaning is required when this pressure differential reaches 0.7 bar.

PV & PVS Series - Plastic Semi-Automatic Screen Filters (Single Body)

ADVANTAGES

Engineered for Continuous Flow

Aytok semi-automatic filters are built to ensure your operations never stop, delivering an uninterrupted supply of clean water even during cleaning cycles. Their smart design uses a pressure differential system to alert the user when a manual cleaning cycle is needed. This simple user-activated flush efficiently purges all contaminants without halting filtration, guaranteeing trouble-free performance and delivering constant reliability when it matters most.

GENERAL FEATURES

| Body Material | PA6GFR30 |

| Cartridge Material | SS304L, PA6GFR30 |

| Maximum Working Pressure | 8 bar ; 116 Psi |

| Minimum Working Pressure | 1 bar ; 14.5 Psi |

| Maximum Working Temperature | 60 °C ; 140°F |

| Control System | Semi Automatic Control |

| Filtration Sensitivity | 20-200 μ (micron) |

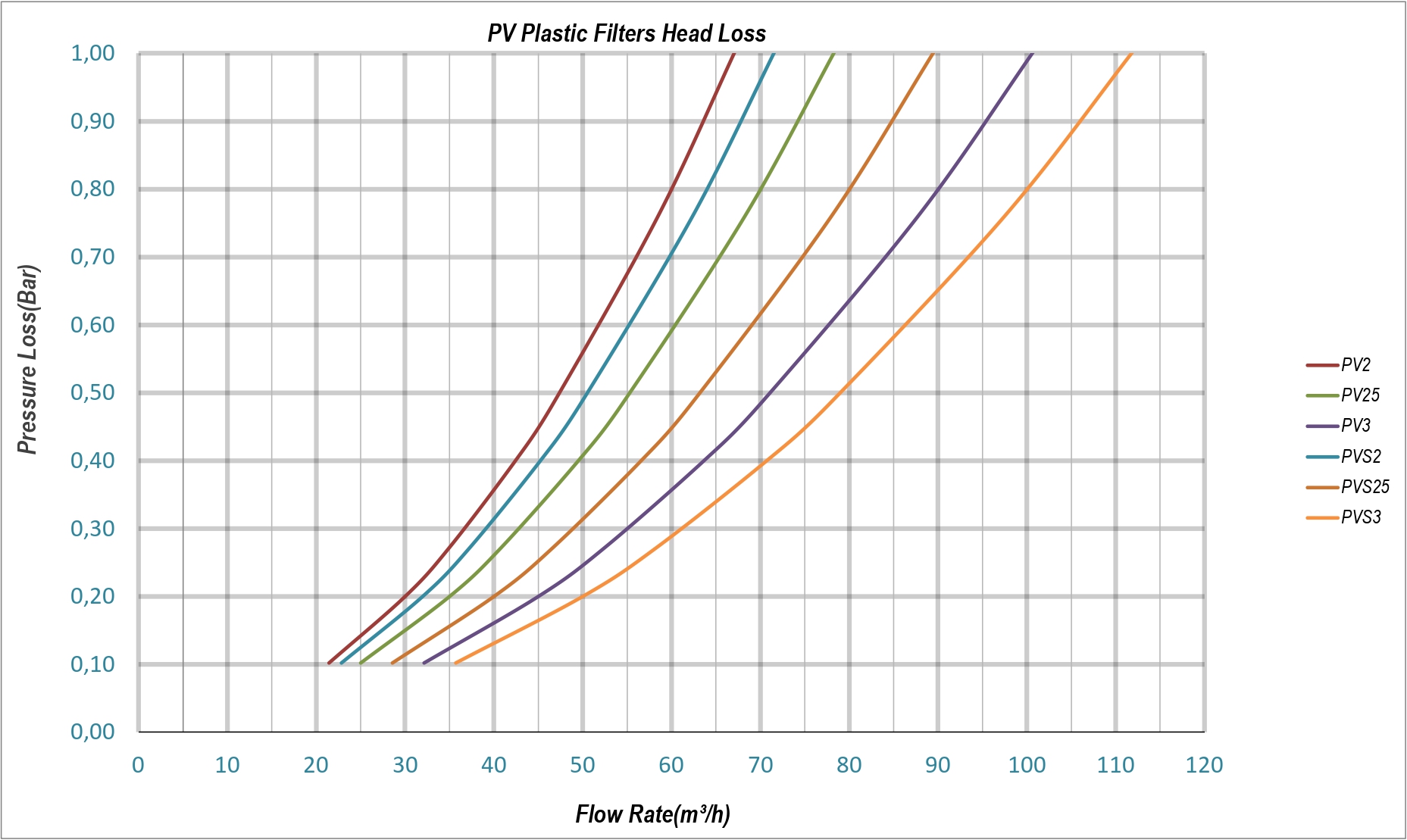

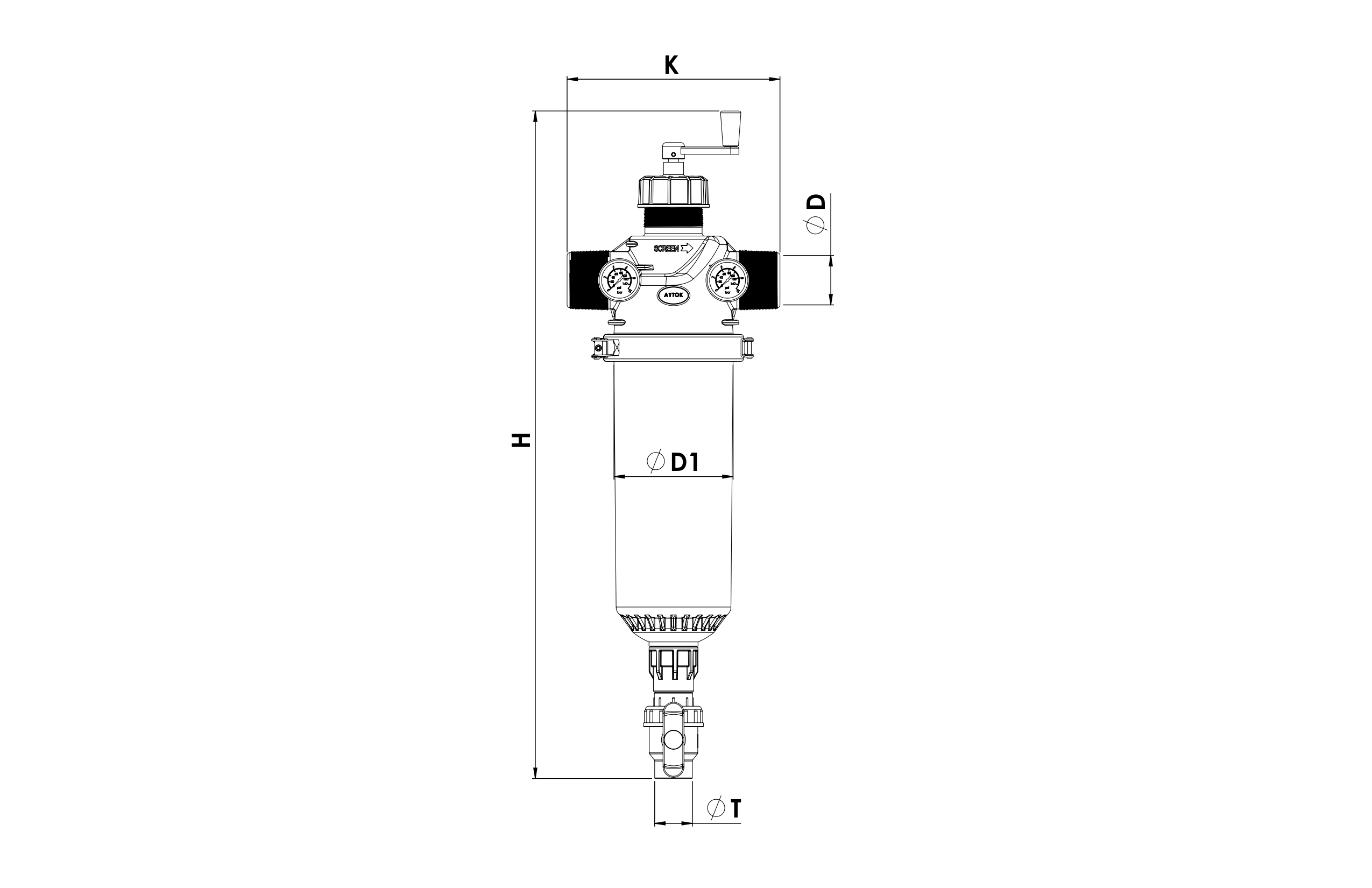

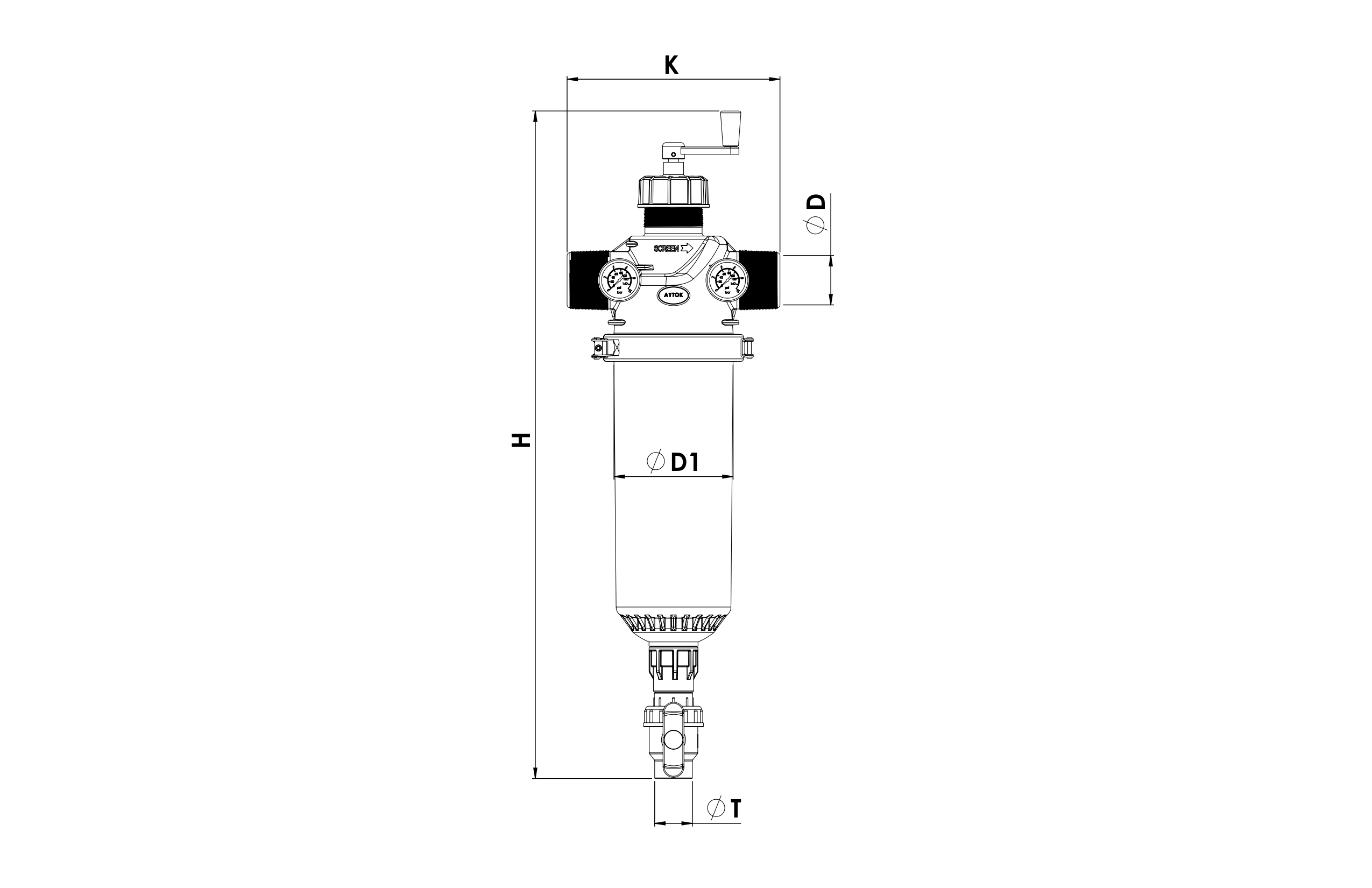

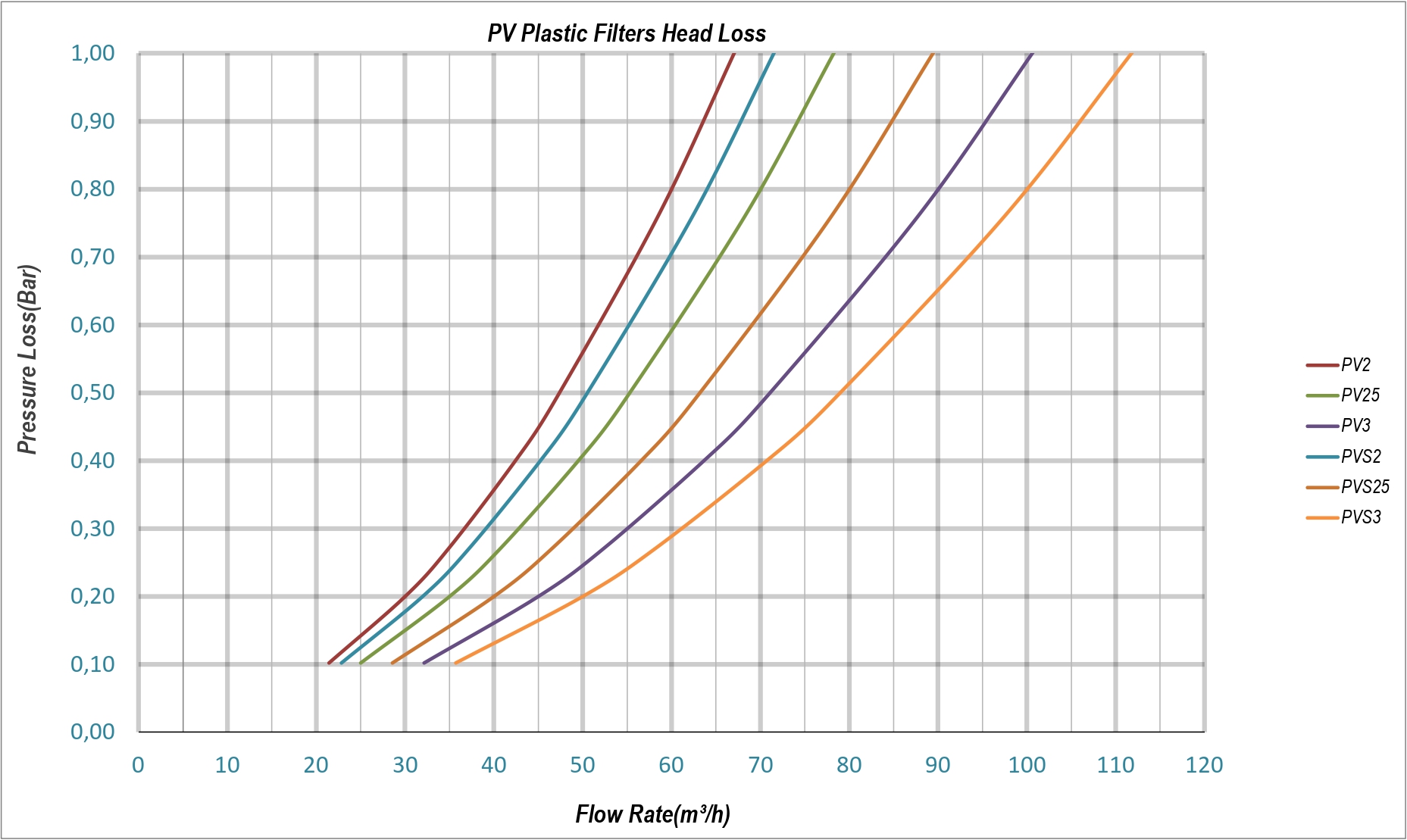

| CODE | D | M | T | D1 | H | K | Flow Rate | Filtration Area | Weight | ||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Inch | DN | Inch | Inch | mm | mm | mm | m³/h | GPM(US) | cm² | kg | |

| PV2 | 2 | 50 | 1/4 | 1 1/2 | 190 | 925 | 335 | 30 | 132 | 1140 | 7,2 |

| PV25 | 2 1/2 | 65 | 1/4 | 1 1/2 | 190 | 925 | 335 | 35 | 154 | 1140 | 7,4 |

| PV3 | 3 | 80 | 1/4 | 1 1/2 | 190 | 925 | 335 | 45 | 198 | 1140 | 7,6 |

| PVS2 | 2 | 50 | 1/4 | 1 1/2 | 190 | 1045 | 335 | 35 | 154 | 1520 | 8,2 |

| PVS25 | 2 1/2 | 65 | 1/4 | 1 1/2 | 190 | 1045 | 335 | 40 | 176 | 1520 | 8,4 |

| PVS3 | 3 | 80 | 1/4 | 1 1/2 | 190 | 1045 | 335 | 50 | 220 | 1520 | 8,7 |

Send us a message

Fill out the form below to contact us.

Ürün Detayı

PV & PVS Series - Plastic Semi-Automatic Screen Filters (Single Body)

GENERAL FEATURES

Cleaning Process

The manual flushing process is initiated by opening the filter’s flush valve and rotating the cleaning handle at a constant speed. This rotation moves a set of internal nozzles across the screen surface. The open valve creates a localized pressure drop, generating a high-velocity suction effect through the nozzles that vacuums contaminants off the screen and discharges them. The cleaning cycle consists of two passes: a primary pass as the handle is turned to its limit, and a secondary pass as it is rotated back to its home position. The process is completed by closing the flush valve.

Working Principle

Water enters the filter and passes through the fine screen element. During operation, contaminants gradually accumulate on the inner surface of the screen. This buildup restricts water flow, creating a pressure differential between the filter’s inlet and outlet. Manual cleaning is required when this pressure differential reaches 0.7 bar.

ADVANTAGES

Powerful Filtration, Smarter Design.

Engineered for Continuous Flow

Aytok semi-automatic filters are built to ensure your operations never stop, delivering an uninterrupted supply of clean water even during cleaning cycles. Their smart design uses a pressure differential system to alert the user when a manual cleaning cycle is needed. This simple user-activated flush efficiently purges all contaminants without halting filtration, guaranteeing trouble-free performance and delivering constant reliability when it matters most.

DÖKÜMANLAR

| CODE | D | M | T | D1 | H | K | Flow Rate | Filtration Area | Weight | ||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Inch | DN | Inch | Inch | mm | mm | mm | m³/h | GPM(US) | cm² | kg | |

| PV2 | 2 | 50 | 1/4 | 1 1/2 | 190 | 925 | 335 | 30 | 132 | 1140 | 7,2 |

| PV25 | 2 1/2 | 65 | 1/4 | 1 1/2 | 190 | 925 | 335 | 35 | 154 | 1140 | 7,4 |

| PV3 | 3 | 80 | 1/4 | 1 1/2 | 190 | 925 | 335 | 45 | 198 | 1140 | 7,6 |

| PVS2 | 2 | 50 | 1/4 | 1 1/2 | 190 | 1045 | 335 | 35 | 154 | 1520 | 8,2 |

| PVS25 | 2 1/2 | 65 | 1/4 | 1 1/2 | 190 | 1045 | 335 | 40 | 176 | 1520 | 8,4 |

| PVS3 | 3 | 80 | 1/4 | 1 1/2 | 190 | 1045 | 335 | 50 | 220 | 1520 | 8,7 |