| Body Material | PA6GFR30 |

| Cartridge Material | PP |

| Maximum Working Pressure | 8 bar ; 116 Psi |

| Minimum Working Pressure | 2 bar ; 29 Psi |

| Maximum Working Temperature | 60 °C ; 140°F |

| Back Washing Time | Time and Pressure Difference Setup |

| Filtration Sensitivity | 20, 50, 100, 130, 200 μ (micron) |

Ürünlerimiz

water_drop Irrigation

Uygulama Alanları

water_drop IRRIGATION

Filter Types

Media Center

Send us a message

Fill out the form below to contact us.

Cleaning Process

Waterborne particles entering the filter are captured on the outer surface of a compressed disc stack, forming a layer of contaminants. This buildup causes the pressure differential between the filter’s inlet and outlet to increase. The system automatically initiates a backwash cycle based on one of two user-defined triggers configured on the control panel: when the pressure differential reaches a preset value, or after a pre-determined time interval has elapsed, whichever occurs first. Upon activation, a three-way valve reverses the water flow direction and opens the discharge line. The pressurized water from the outlet acts on an internal spring mechanism, releasing the compression on the discs and allowing them to separate. This reverse flow, combined with the grooved design of the discs, causes them to spin and effectively flushes the accumulated particles from their surfaces out through the drainage line.

Working Principle

Water enters the filter and passes through the disc stack. During operation, contaminants accumulate on the outer surface of the discs. This buildup creates a pressure difference between the inlet and outlet of the filter, obstructing water flow. When this pressure difference reaches a threshold of 0.7 bar, a cleaning cycle is required, which can be initiated manually or automatically.

PSC Series - Plastic Self-Cleaning Disc Filters

GENERAL FEATURES

| Body Material | PA6GFR30 |

| Cartridge Material | PP |

| Maximum Working Pressure | 8 bar ; 116 Psi |

| Minimum Working Pressure | 2 bar ; 29 Psi |

| Maximum Working Temperature | 60 °C ; 140°F |

| Back Washing Time | Time and Pressure Difference Setup |

| Filtration Sensitivity | 20, 50, 100, 130, 200 μ (micron) |

ADVANTAGES

Cleaning Process

Waterborne particles entering the filter are captured on the outer surface of a compressed disc stack, forming a layer of contaminants. This buildup causes the pressure differential between the filter’s inlet and outlet to increase. The system automatically initiates a backwash cycle based on one of two user-defined triggers configured on the control panel: when the pressure differential reaches a preset value, or after a pre-determined time interval has elapsed, whichever occurs first. Upon activation, a three-way valve reverses the water flow direction and opens the discharge line. The pressurized water from the outlet acts on an internal spring mechanism, releasing the compression on the discs and allowing them to separate. This reverse flow, combined with the grooved design of the discs, causes them to spin and effectively flushes the accumulated particles from their surfaces out through the drainage line.

Working Principle

Water enters the filter and passes through the disc stack. During operation, contaminants accumulate on the outer surface of the discs. This buildup creates a pressure difference between the inlet and outlet of the filter, obstructing water flow. When this pressure difference reaches a threshold of 0.7 bar, a cleaning cycle is required, which can be initiated manually or automatically.

PSC Series - Plastic Self-Cleaning Disc Filters

ADVANTAGES

Designed for Autonomous Reliability.

Aytok PSC filters provide fully autonomous, self-cleaning filtration for demanding applications. Their robust design combines a high-strength polyamide housing with a precision-engineered backwash mechanism, ensuring exceptional long-term durability. This advanced, intervention-free system operates automatically based on time or pressure differential, guaranteeing years of trouble-free performance and providing peace of mind for your critical operations.

GENERAL FEATURES

| Body Material | PA6GFR30 |

| Cartridge Material | PP |

| Maximum Working Pressure | 8 bar ; 116 Psi |

| Minimum Working Pressure | 2 bar ; 29 Psi |

| Maximum Working Temperature | 60 °C ; 140°F |

| Back Washing Time | Time and Pressure Difference Setup |

| Filtration Sensitivity | 20, 50, 100, 130, 200 μ (micron) |

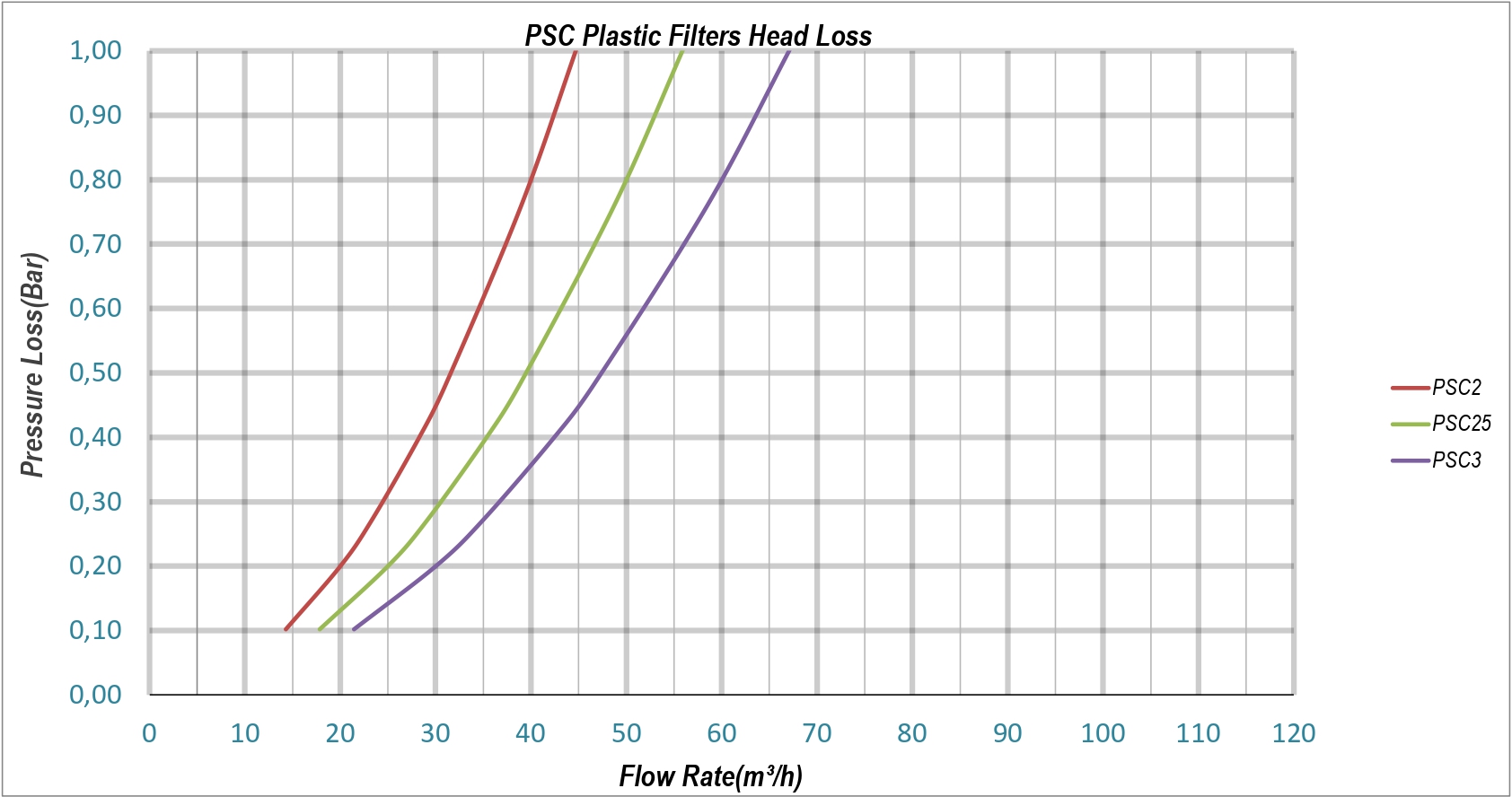

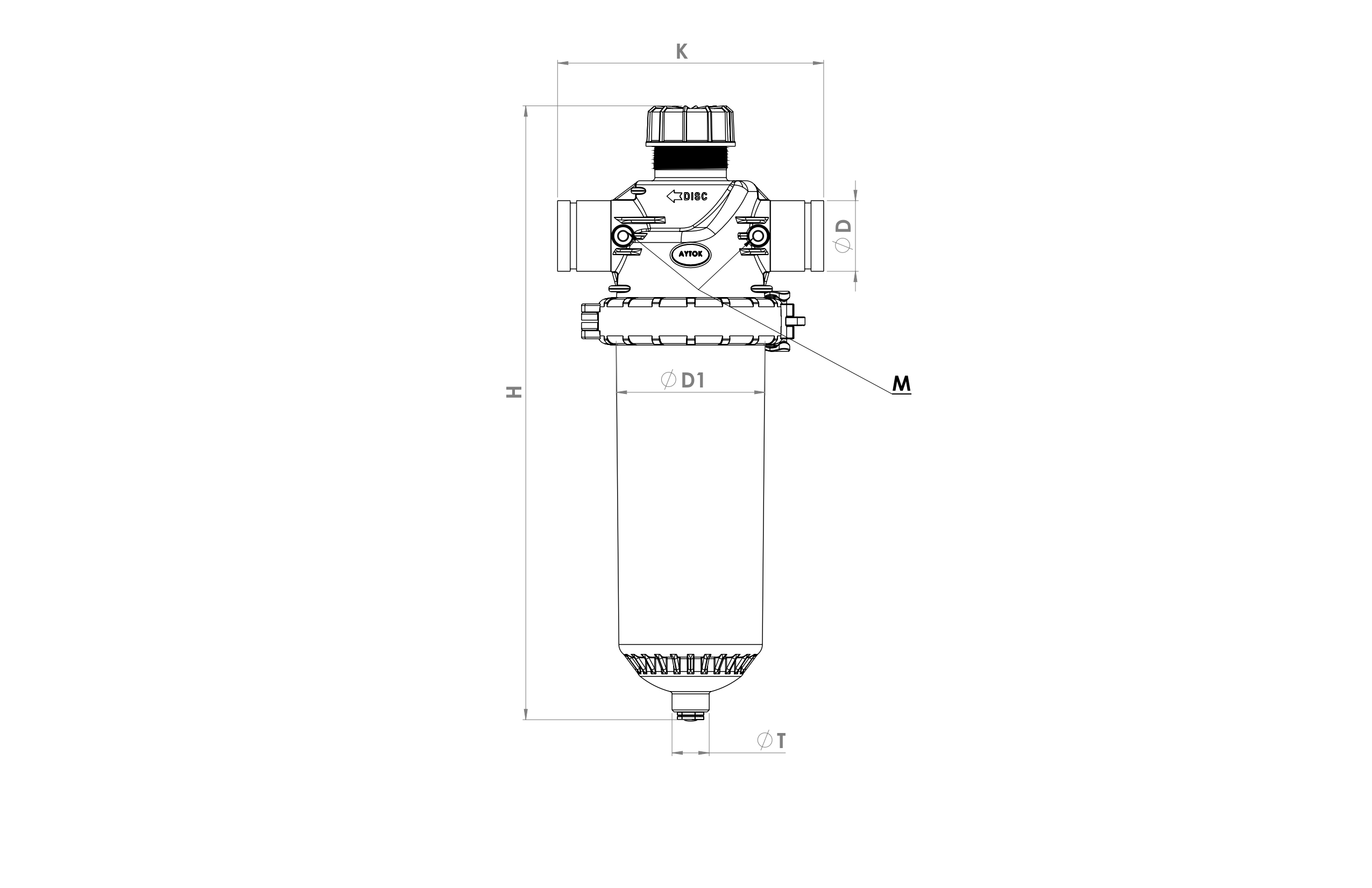

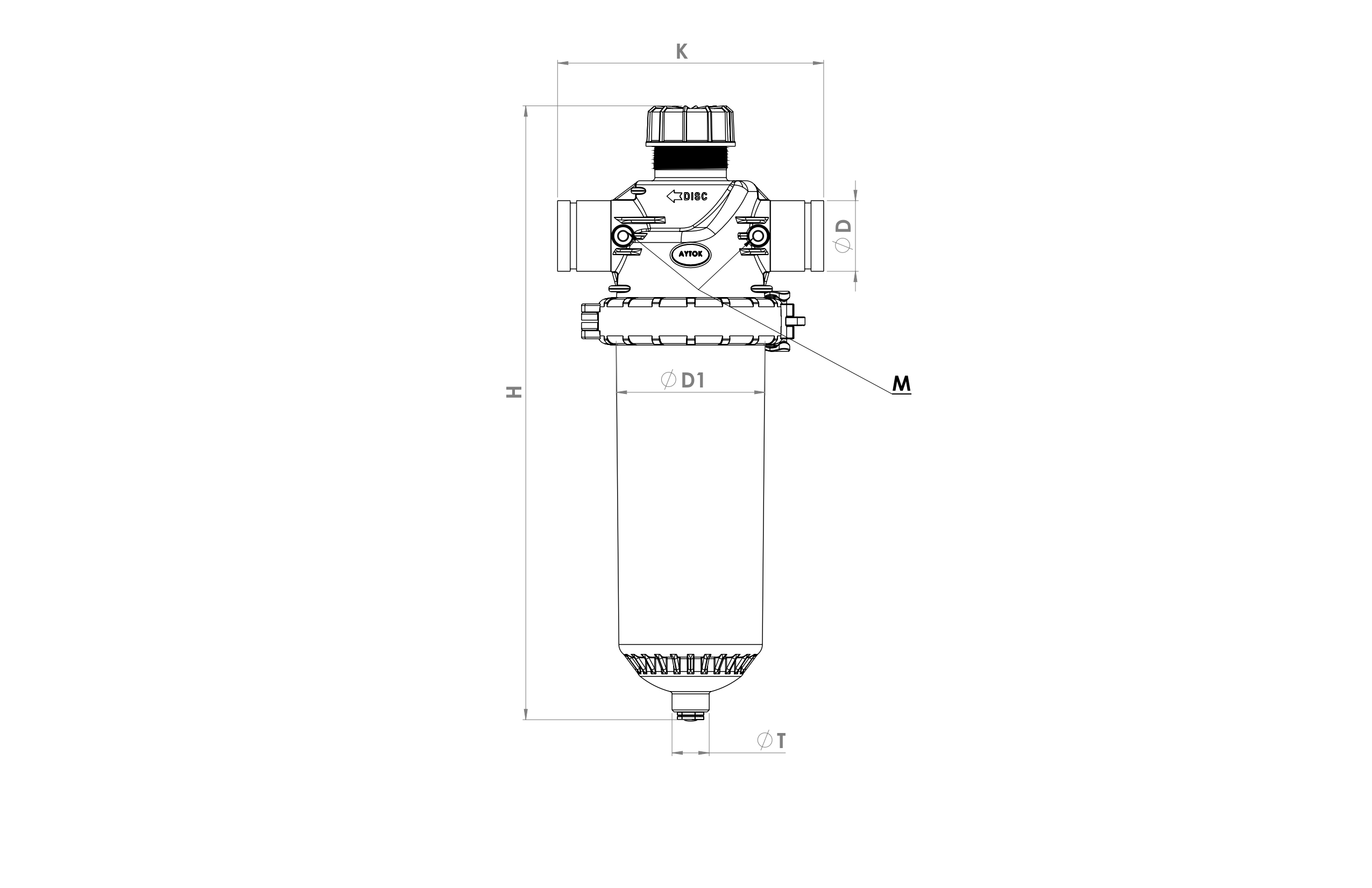

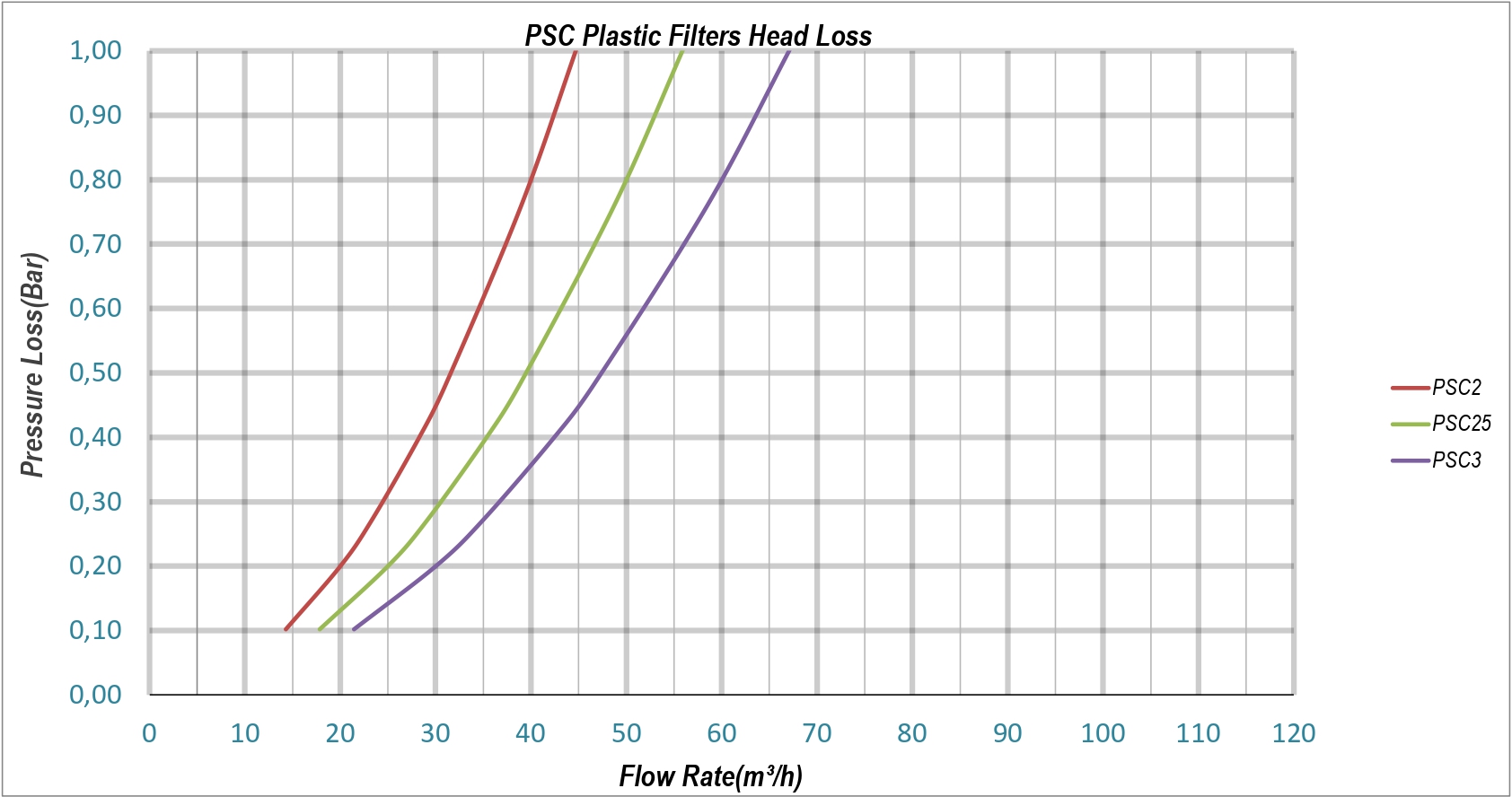

| CODE | D | M | T | D1 | H | K | Flow Rate | Filtration Area | Weight | ||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Inch | DN | Inch | Inch | mm | mm | mm | m³/h | GPM(US) | cm² | kg | |

| PSC2 | 2 | 50 | 1/4 | 3/4 | 190 | 765 | 335 | 20 | 88 | 1550 | 9,6 |

| PSC25 | 2 1/2 | 65 | 1/4 | 3/4 | 190 | 765 | 335 | 25 | 110 | 1550 | 9,7 |

| PSC3 | 3 | 80 | 1/4 | 3/4 | 190 | 765 | 335 | 30 | 132 | 1550 | 9,8 |

Send us a message

Fill out the form below to contact us.

Ürün Detayı

PSC Series - Plastic Self-Cleaning Disc Filters

GENERAL FEATURES

Cleaning Process

Waterborne particles entering the filter are captured on the outer surface of a compressed disc stack, forming a layer of contaminants. This buildup causes the pressure differential between the filter’s inlet and outlet to increase. The system automatically initiates a backwash cycle based on one of two user-defined triggers configured on the control panel: when the pressure differential reaches a preset value, or after a pre-determined time interval has elapsed, whichever occurs first. Upon activation, a three-way valve reverses the water flow direction and opens the discharge line. The pressurized water from the outlet acts on an internal spring mechanism, releasing the compression on the discs and allowing them to separate. This reverse flow, combined with the grooved design of the discs, causes them to spin and effectively flushes the accumulated particles from their surfaces out through the drainage line.

Working Principle

Water enters the filter and passes through the disc stack. During operation, contaminants accumulate on the outer surface of the discs. This buildup creates a pressure difference between the inlet and outlet of the filter, obstructing water flow. When this pressure difference reaches a threshold of 0.7 bar, a cleaning cycle is required, which can be initiated manually or automatically.

ADVANTAGES

Powerful Filtration, Smarter Design.

Designed for Autonomous Reliability.

Aytok PSC filters provide fully autonomous, self-cleaning filtration for demanding applications. Their robust design combines a high-strength polyamide housing with a precision-engineered backwash mechanism, ensuring exceptional long-term durability. This advanced, intervention-free system operates automatically based on time or pressure differential, guaranteeing years of trouble-free performance and providing peace of mind for your critical operations.

DÖKÜMANLAR

| CODE | D | M | T | D1 | H | K | Flow Rate | Filtration Area | Weight | ||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Inch | DN | Inch | Inch | mm | mm | mm | m³/h | GPM(US) | cm² | kg | |

| PSC2 | 2 | 50 | 1/4 | 3/4 | 190 | 765 | 335 | 20 | 88 | 1550 | 9,6 |

| PSC25 | 2 1/2 | 65 | 1/4 | 3/4 | 190 | 765 | 335 | 25 | 110 | 1550 | 9,7 |

| PSC3 | 3 | 80 | 1/4 | 3/4 | 190 | 765 | 335 | 30 | 132 | 1550 | 9,8 |