| Body Material | PA6GFR30 |

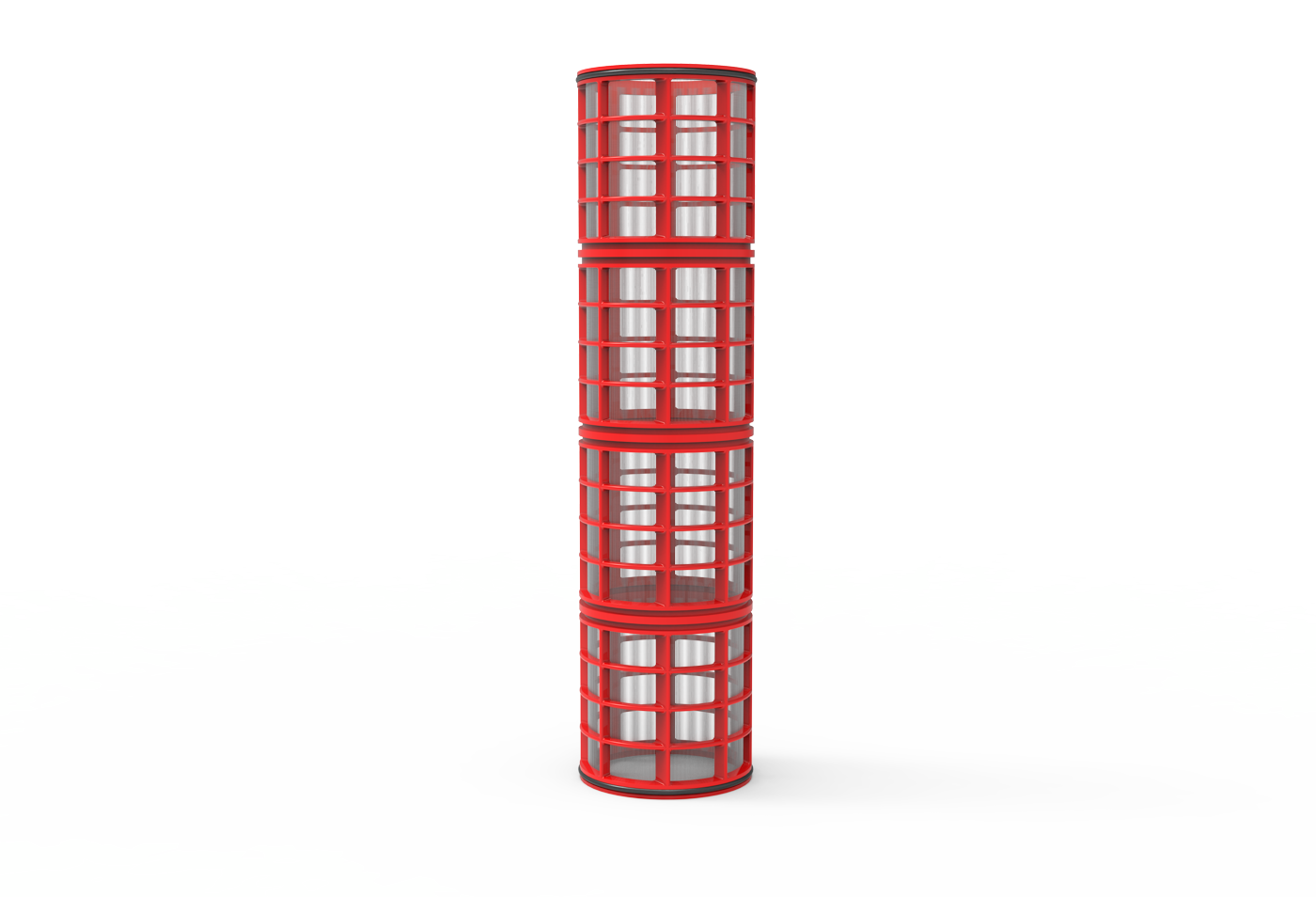

| Cartridge Material | SS304L, PA6GFR30 |

| Maximum Working Pressure | 8 bar ; 116 Psi |

| Minimum Working Pressure | 2 bar ; 29 Psi |

| Maximum Working Temperature | 60 °C ; 140°F |

| Back Washing Time | Time and Pressure Difference Setup |

| Control System | Electronic (AC/DC) |

| Filtration Sensitivity | 20-2000 μ (micron) |

Ürünlerimiz

water_drop Irrigation

Uygulama Alanları

water_drop IRRIGATION

Filter Types

Media Center

Send us a message

Fill out the form below to contact us.

Cleaning Process

The backwash sequence is triggered for an individual filter unit by either a preset pressure differential or a time interval. Upon activation, the control unit opens the discharge valve of the designated unit. Exposing this valve to atmospheric pressure creates a significant pressure drop, inducing a powerful reverse flow. This reverse flow drives a hydraulic turbine, which rotates the cleaning collector while a piston moves it linearly. The collector's nozzles generate high-velocity suction, vacuuming accumulated debris from the inner screen and expelling it through the drainage pipe. This combined helical motion ensures a systematic and thorough cleaning of the entire screen surface. During the backwash process, both sides of the double-body filter continue filtering simultaneously — only a temporary pressure drop is observed. The cleaning sequence is then performed sequentially for each side of the double-body unit. Once complete, the discharge valve closes and the collector returns to its home position, concluding the cycle for that unit. Throughout this self-cleaning process, system filtration continues uninterrupted.

Working Principle

Water enters the filter and passes sequentially through a coarse and then a fine screen. As contaminants accumulate on the inner surface of the fine screen, a pressure differential is created between the inlet and outlet. A backwash cycle is automatically initiated based on one of two conditions: when this pressure differential reaches a predetermined setpoint, or after a preset time interval has elapsed, whichever occurs first.

PD-HF Series - Plastic Self-Cleaning Screen Filters (Double Body)

GENERAL FEATURES

| Body Material | PA6GFR30 |

| Cartridge Material | SS304L, PA6GFR30 |

| Maximum Working Pressure | 8 bar ; 116 Psi |

| Minimum Working Pressure | 2 bar ; 29 Psi |

| Maximum Working Temperature | 60 °C ; 140°F |

| Back Washing Time | Time and Pressure Difference Setup |

| Control System | Electronic (AC/DC) |

| Filtration Sensitivity | 20-2000 μ (micron) |

ADVANTAGES

Cleaning Process

The backwash sequence is triggered for an individual filter unit by either a preset pressure differential or a time interval. Upon activation, the control unit opens the discharge valve of the designated unit. Exposing this valve to atmospheric pressure creates a significant pressure drop, inducing a powerful reverse flow. This reverse flow drives a hydraulic turbine, which rotates the cleaning collector while a piston moves it linearly. The collector's nozzles generate high-velocity suction, vacuuming accumulated debris from the inner screen and expelling it through the drainage pipe. This combined helical motion ensures a systematic and thorough cleaning of the entire screen surface. During the backwash process, both sides of the double-body filter continue filtering simultaneously — only a temporary pressure drop is observed. The cleaning sequence is then performed sequentially for each side of the double-body unit. Once complete, the discharge valve closes and the collector returns to its home position, concluding the cycle for that unit. Throughout this self-cleaning process, system filtration continues uninterrupted.

Working Principle

Water enters the filter and passes sequentially through a coarse and then a fine screen. As contaminants accumulate on the inner surface of the fine screen, a pressure differential is created between the inlet and outlet. A backwash cycle is automatically initiated based on one of two conditions: when this pressure differential reaches a predetermined setpoint, or after a preset time interval has elapsed, whichever occurs first.

PD-HF Series - Plastic Self-Cleaning Screen Filters (Double Body)

ADVANTAGES

Double the Performance. Unleash the Power.

Smart. Automated. Unstoppable. Now amplified. Introducing the dual-body version of our Plastic Automatic Filter. We've taken our revolutionary intelligent automation and corrosion-proof body and doubled the filtration surface area and flow rate capacity. The result? An unrelenting flow of ultra-clean water and unrivaled system protection, even for the most demanding industrial applications.

GENERAL FEATURES

| Body Material | PA6GFR30 |

| Cartridge Material | SS304L, PA6GFR30 |

| Maximum Working Pressure | 8 bar ; 116 Psi |

| Minimum Working Pressure | 2 bar ; 29 Psi |

| Maximum Working Temperature | 60 °C ; 140°F |

| Back Washing Time | Time and Pressure Difference Setup |

| Control System | Electronic (AC/DC) |

| Filtration Sensitivity | 20-2000 μ (micron) |

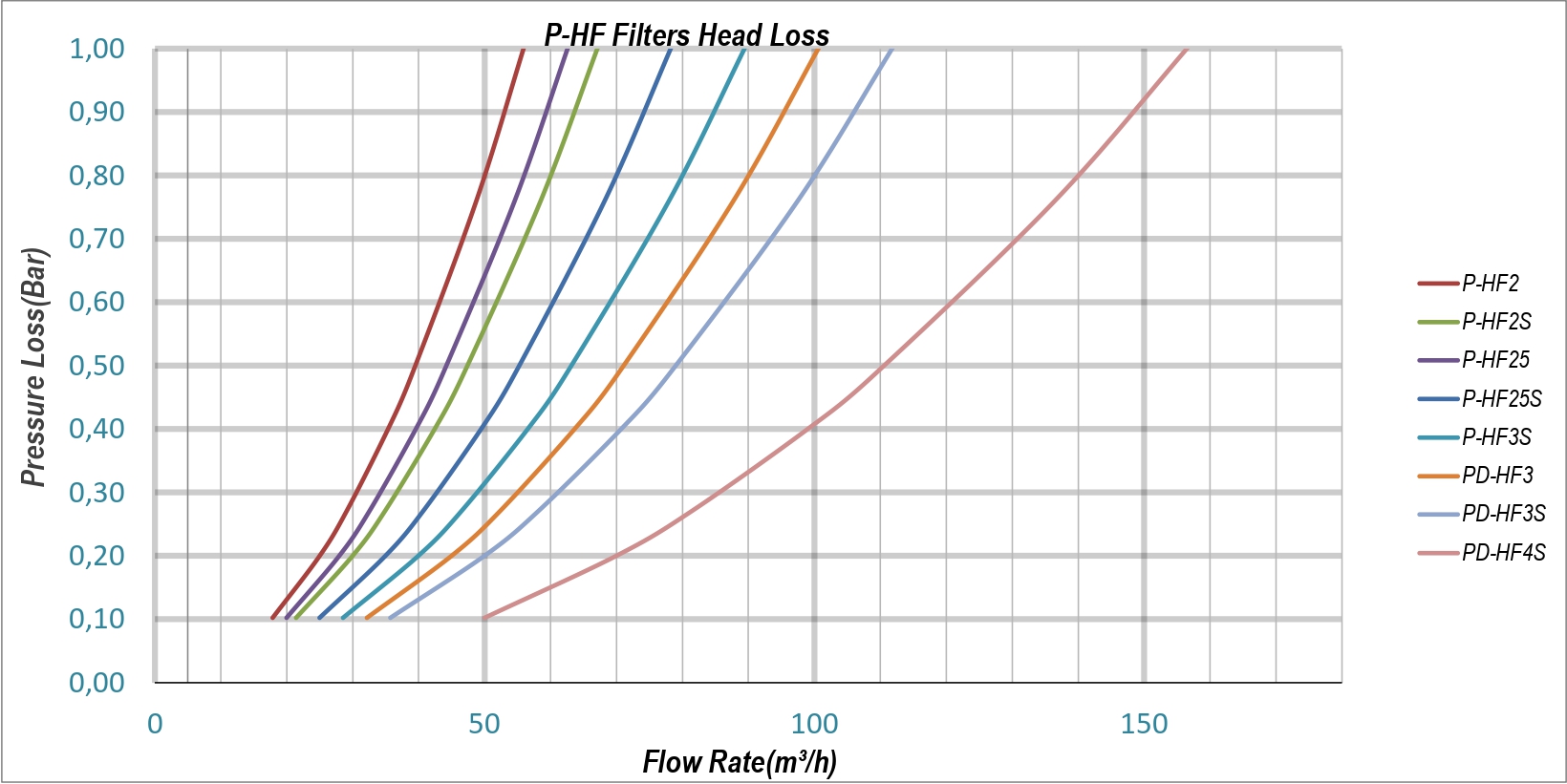

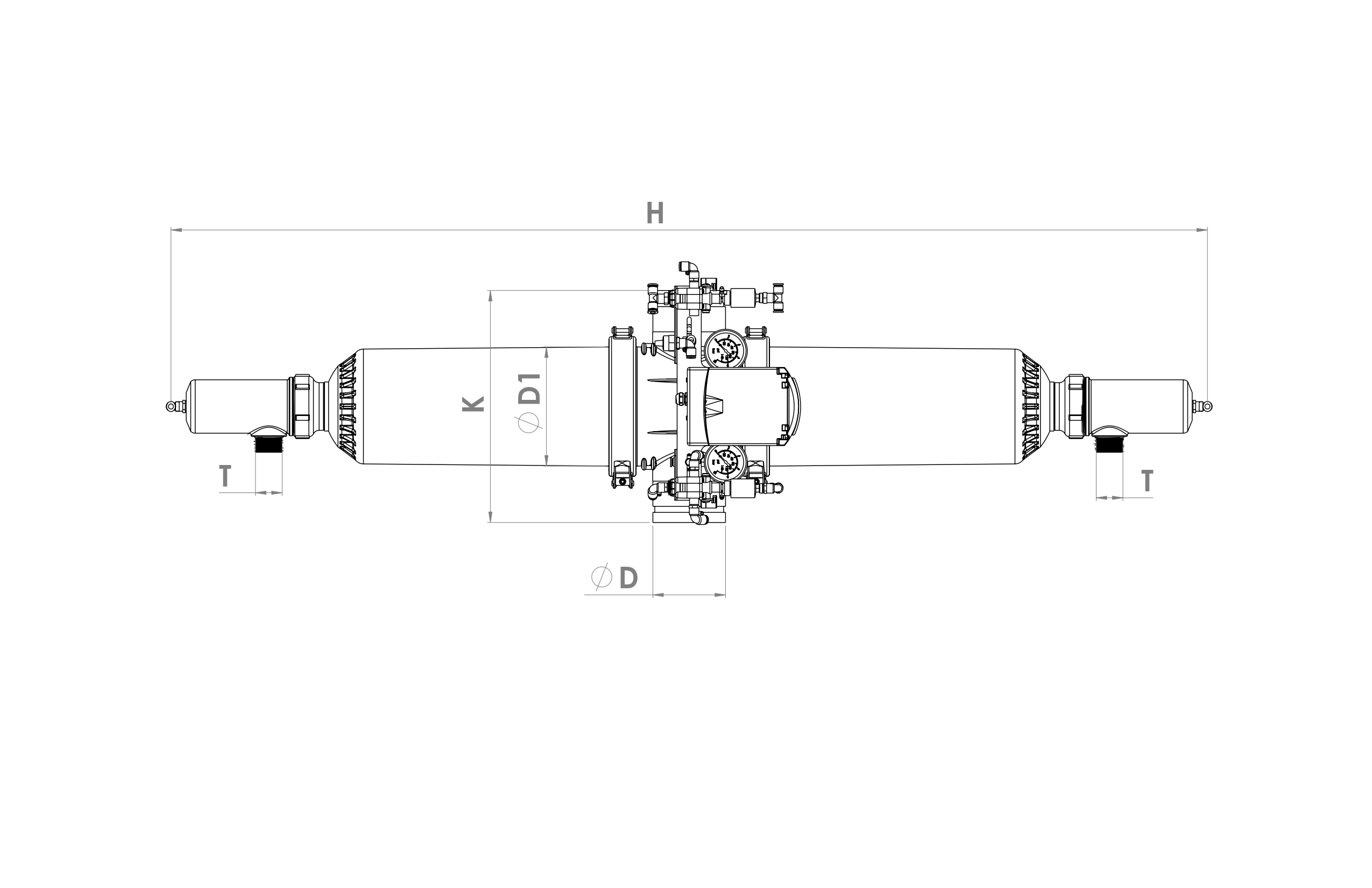

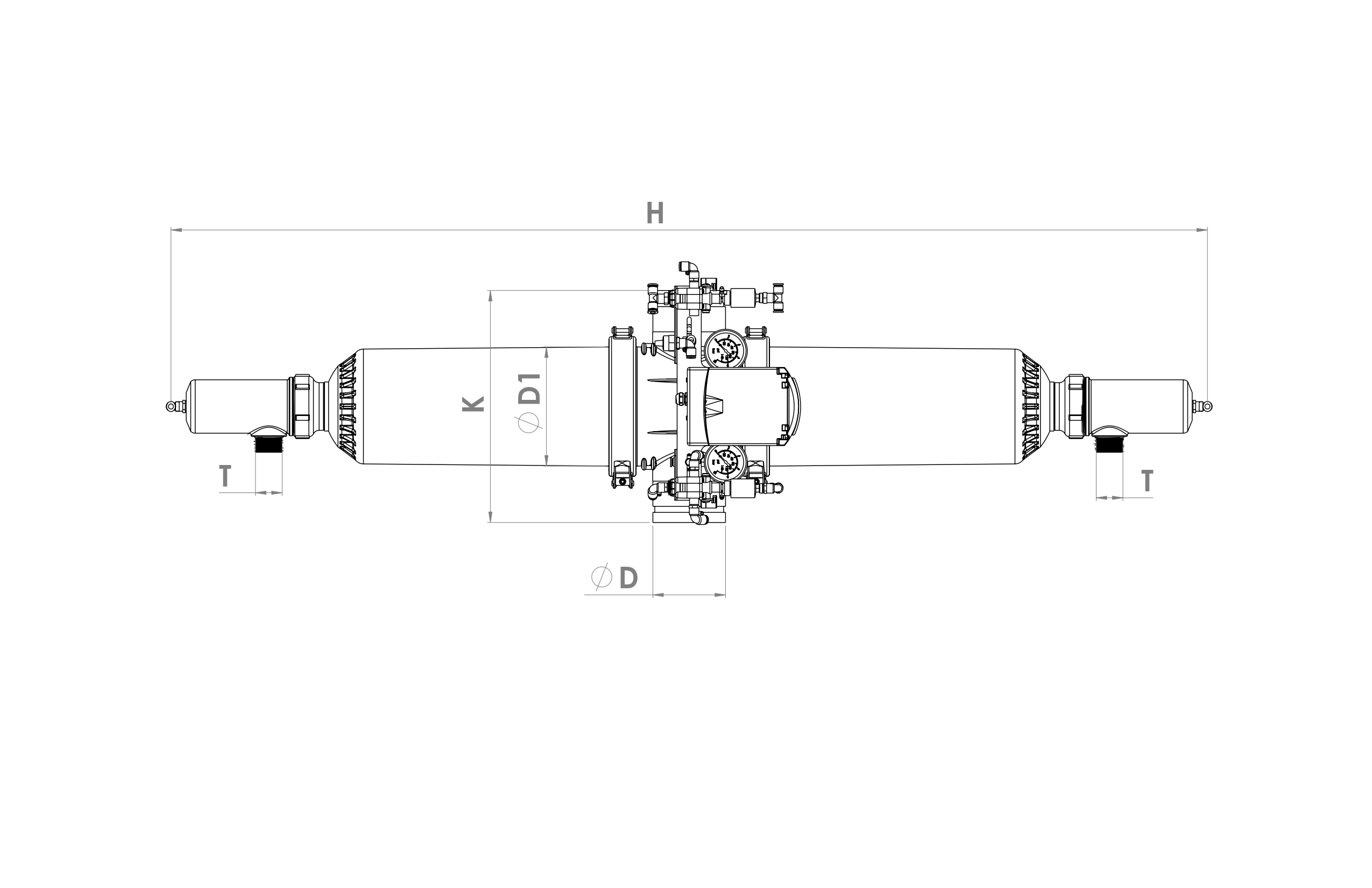

| CODE | Inlet/Outlet (D) | D1 | K | T | H | Drain Flow Rate | Main Flow Rate | Filtration Area cm² |

Nozzle Qty. |

Screen Qty. |

|||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Inch | DN | mm | mm | Inch | mm | L/s | GPM(US) | m³/h | GPM(US) | ||||

| PD-HF3 | 3 | 80 | 190 | 365 | 1,25 | 1410 | 1,9 | 29 | 45 | 198 | 1520 | 8 | 4 |

| PD-HF3S | 3 | 80 | 190 | 365 | 1,25 | 1650 | 2,8 | 44 | 50 | 220 | 2280 | 12 | 6 |

| PD-HF4S | 4 | 100 | 190 | 365 | 1,25 | 1650 | 2,8 | 44 | 70 | 308 | 2280 | 12 | 6 |

Send us a message

Fill out the form below to contact us.

Ürün Detayı

PD-HF Series - Plastic Self-Cleaning Screen Filters (Double Body)

GENERAL FEATURES

Cleaning Process

The backwash sequence is triggered for an individual filter unit by either a preset pressure differential or a time interval. Upon activation, the control unit opens the discharge valve of the designated unit. Exposing this valve to atmospheric pressure creates a significant pressure drop, inducing a powerful reverse flow. This reverse flow drives a hydraulic turbine, which rotates the cleaning collector while a piston moves it linearly. The collector's nozzles generate high-velocity suction, vacuuming accumulated debris from the inner screen and expelling it through the drainage pipe. This combined helical motion ensures a systematic and thorough cleaning of the entire screen surface. During the backwash process, both sides of the double-body filter continue filtering simultaneously — only a temporary pressure drop is observed. The cleaning sequence is then performed sequentially for each side of the double-body unit. Once complete, the discharge valve closes and the collector returns to its home position, concluding the cycle for that unit. Throughout this self-cleaning process, system filtration continues uninterrupted.

Working Principle

Water enters the filter and passes sequentially through a coarse and then a fine screen. As contaminants accumulate on the inner surface of the fine screen, a pressure differential is created between the inlet and outlet. A backwash cycle is automatically initiated based on one of two conditions: when this pressure differential reaches a predetermined setpoint, or after a preset time interval has elapsed, whichever occurs first.

ADVANTAGES

Powerful Filtration, Smarter Design.

Double the Performance. Unleash the Power.

Smart. Automated. Unstoppable. Now amplified. Introducing the dual-body version of our Plastic Automatic Filter. We've taken our revolutionary intelligent automation and corrosion-proof body and doubled the filtration surface area and flow rate capacity. The result? An unrelenting flow of ultra-clean water and unrivaled system protection, even for the most demanding industrial applications.

DÖKÜMANLAR

| CODE | Inlet/Outlet (D) | D1 | K | T | H | Drain Flow Rate | Main Flow Rate | Filtration Area cm² |

Nozzle Qty. |

Screen Qty. |

|||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Inch | DN | mm | mm | Inch | mm | L/s | GPM(US) | m³/h | GPM(US) | ||||

| PD-HF3 | 3 | 80 | 190 | 365 | 1,25 | 1410 | 1,9 | 29 | 45 | 198 | 1520 | 8 | 4 |

| PD-HF3S | 3 | 80 | 190 | 365 | 1,25 | 1650 | 2,8 | 44 | 50 | 220 | 2280 | 12 | 6 |

| PD-HF4S | 4 | 100 | 190 | 365 | 1,25 | 1650 | 2,8 | 44 | 70 | 308 | 2280 | 12 | 6 |