| Body Material | S235JR |

| Screen Material | SS304L, PA6GFR30 |

| Maximum Working Pressure | 8 bar ; 116 Psi |

| Maximum Working Temperature | 60 °C ; 140°F |

| Filtration Sensitivity | 20-2000 μ (micron) |

| Painting Method | Electrostatic Powder Coating |

| Paint Coating Material | Epoxy-Polyester |

Ürünlerimiz

water_drop Irrigation

Uygulama Alanları

water_drop IRRIGATION

Filter Types

Media Center

Send us a message

Fill out the form below to contact us.

Cleaning Process

Manual cleaning is required when the pressure differential, monitored by manometers, indicates that the filter is clogged. The process begins by shutting down the system and depressurizing the filter. The cover is then removed and the screen cartridge is extracted. The cleaning principle for a screen filter is direct: the screen is thoroughly cleaned with pressurized water to remove all accumulated debris. After cleaning, the cartridge is reinstalled, and the filter is returned to service.

Working Principle

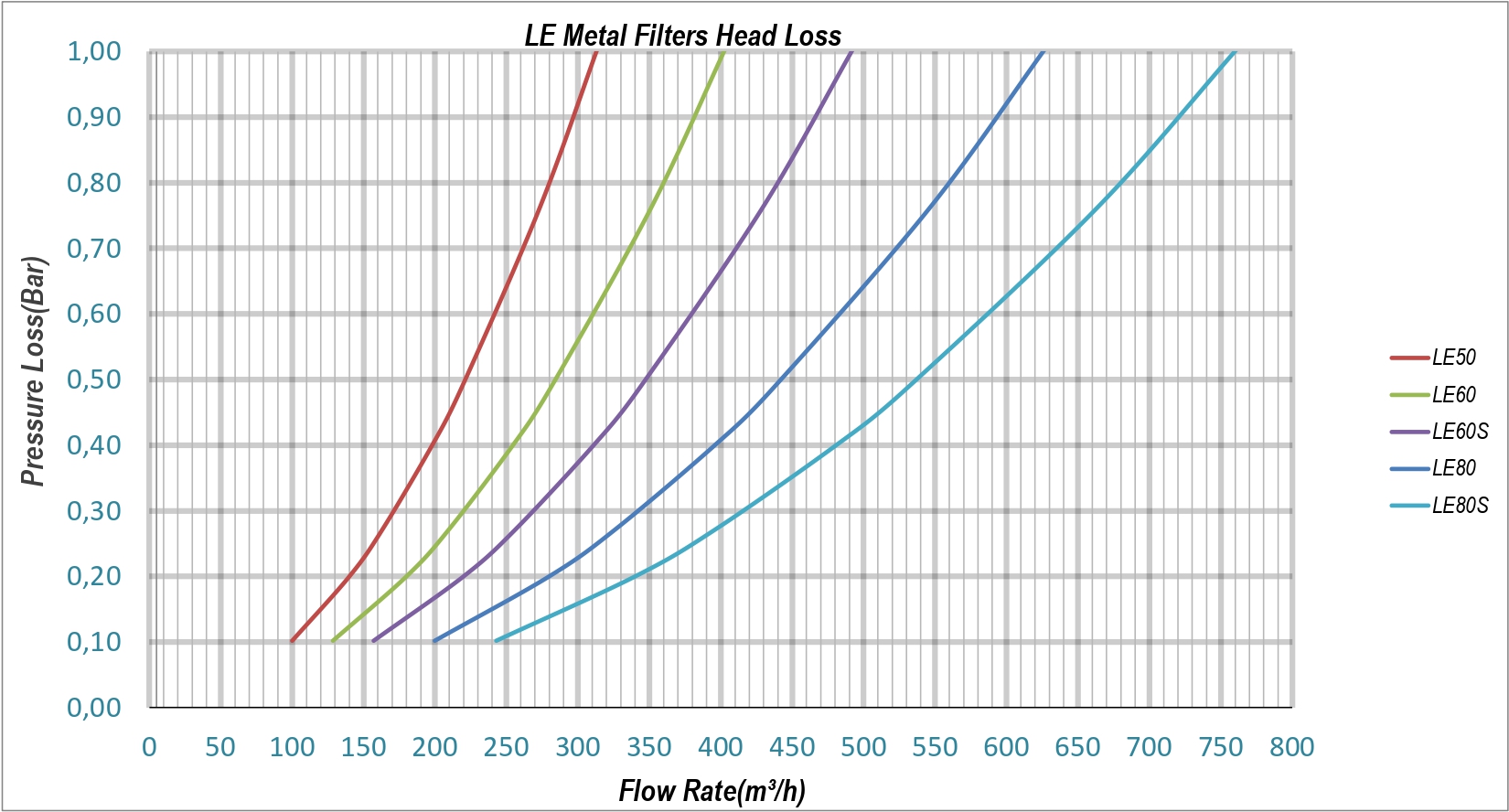

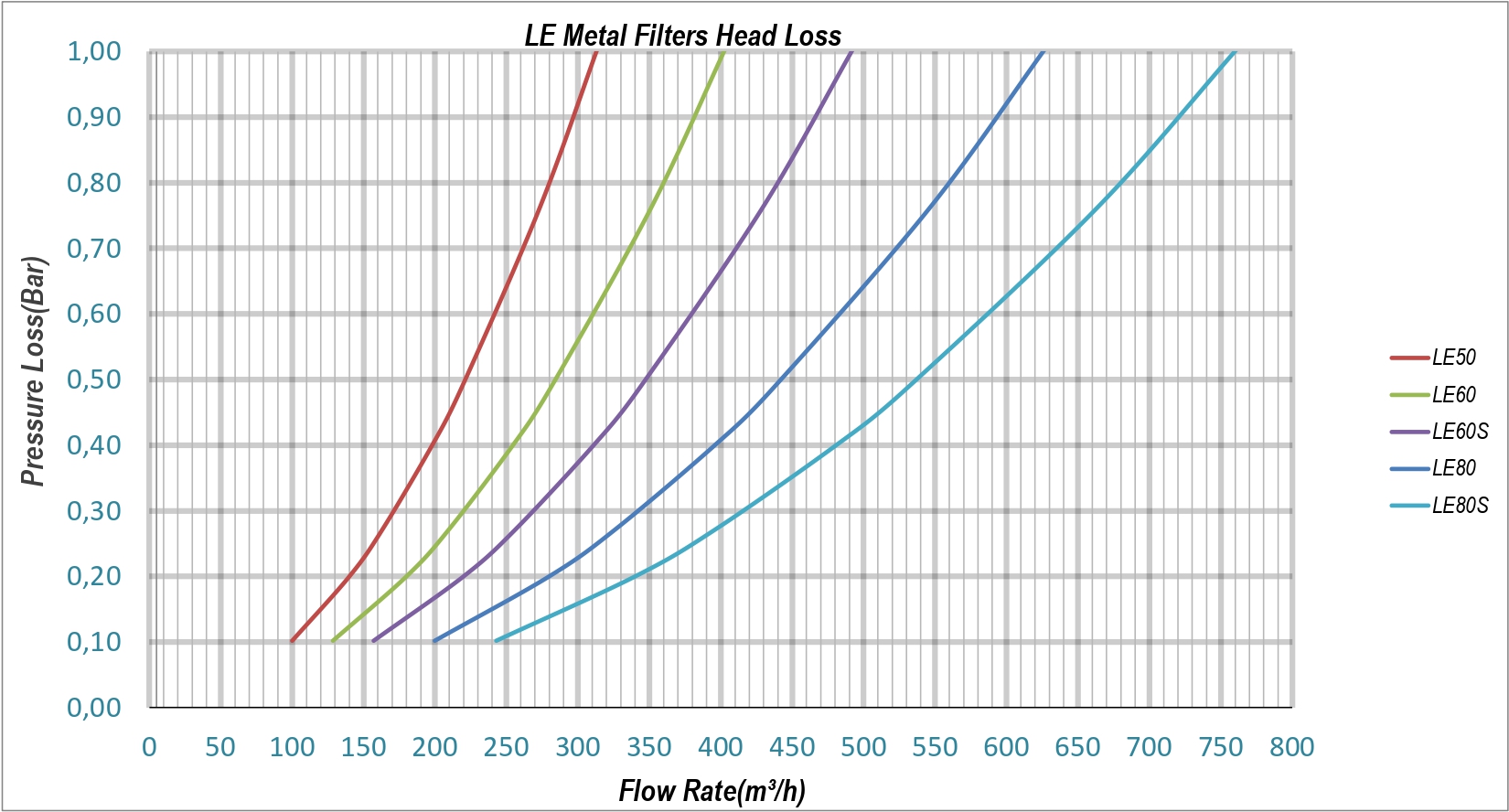

Water enters the filter and passes through the fine screen. As it flows toward the outlet, contaminants gradually accumu - late on the inner surface of the screen. This buildup creates a pressure difference between the inlet and outlet. To ensure proper performance, the filter must be cleaned by the time the pressure difference reaches 0.7 bar.

LE Series - Vertical Metal Screen Filters

GENERAL FEATURES

| Body Material | S235JR |

| Screen Material | SS304L, PA6GFR30 |

| Maximum Working Pressure | 8 bar ; 116 Psi |

| Maximum Working Temperature | 60 °C ; 140°F |

| Filtration Sensitivity | 20-2000 μ (micron) |

| Painting Method | Electrostatic Powder Coating |

| Paint Coating Material | Epoxy-Polyester |

ADVANTAGES

Cleaning Process

Manual cleaning is required when the pressure differential, monitored by manometers, indicates that the filter is clogged. The process begins by shutting down the system and depressurizing the filter. The cover is then removed and the screen cartridge is extracted. The cleaning principle for a screen filter is direct: the screen is thoroughly cleaned with pressurized water to remove all accumulated debris. After cleaning, the cartridge is reinstalled, and the filter is returned to service.

Working Principle

Water enters the filter and passes through the fine screen. As it flows toward the outlet, contaminants gradually accumu - late on the inner surface of the screen. This buildup creates a pressure difference between the inlet and outlet. To ensure proper performance, the filter must be cleaned by the time the pressure difference reaches 0.7 bar.

LE Series - Vertical Metal Screen Filters

ADVANTAGES

The Power of Capacity. The Simplicity of Design.

When your system demands higher flow rates, the LE Manual Screen Filter delivers. Its high-capacity body is engineered to maximize the screen's surface area, enabling significantly greater throughput than standard designs. It maintains the elegant, motor-free principle of our manual series, operating solely on your system's pressure for energy-free, low-maintenance performance. Engineered for durability, this is the definitive solution for your most challenging applications.

GENERAL FEATURES

| Body Material | S235JR |

| Screen Material | SS304L, PA6GFR30 |

| Maximum Working Pressure | 8 bar ; 116 Psi |

| Maximum Working Temperature | 60 °C ; 140°F |

| Filtration Sensitivity | 20-2000 μ (micron) |

| Painting Method | Electrostatic Powder Coating |

| Paint Coating Material | Epoxy-Polyester |

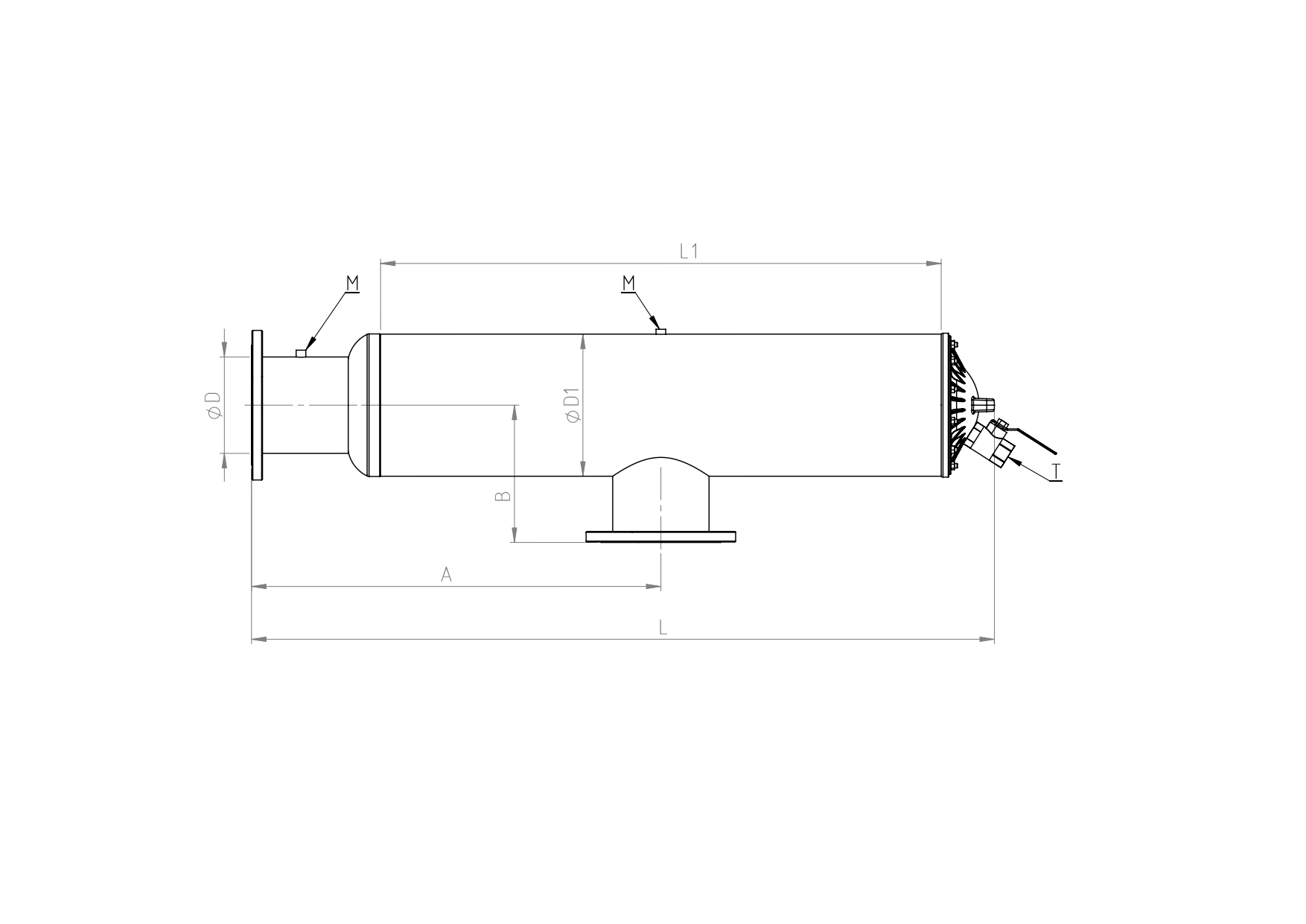

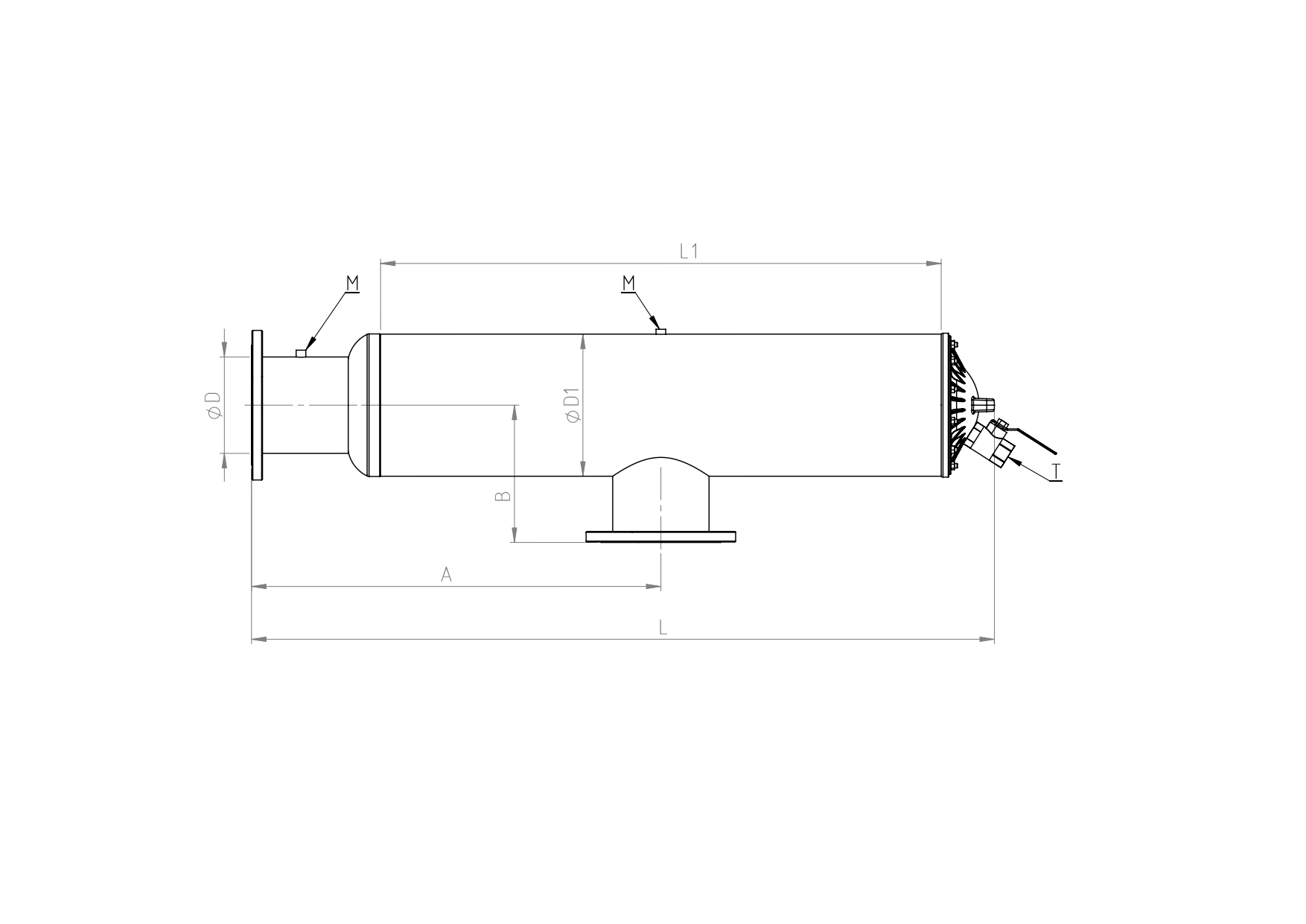

| CODE | Inch | mm | Flow Rate | Weight kg |

|||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| D | D1 | M | T | A | B | L | L1 | m³/h | GPM(US) | ||

| LE50 | 5 | 10 | 1/4 | 1 | 610 | 287 | 1055 | 640 | 140 | 616 | 46 |

| LE60 | 6 | 10 | 1/4 | 1 | 710 | 287 | 1255 | 840 | 180 | 792 | 58 |

| LE60S | 6 | 12 | 1/4 | 1 | 810 | 287 | 1455 | 1040 | 220 | 968 | 68 |

| LE80 | 8 | 12 | 1/4 | 1 | 810 | 287 | 1455 | 1040 | 280 | 1232 | 70 |

| LE80S | 8 | 12 | 1/4 | 1 | 930 | 312 | 1690 | 1275 | 340 | 1496 | 88 |

Send us a message

Fill out the form below to contact us.

Ürün Detayı

LE Series - Vertical Metal Screen Filters

GENERAL FEATURES

Cleaning Process

Manual cleaning is required when the pressure differential, monitored by manometers, indicates that the filter is clogged. The process begins by shutting down the system and depressurizing the filter. The cover is then removed and the screen cartridge is extracted. The cleaning principle for a screen filter is direct: the screen is thoroughly cleaned with pressurized water to remove all accumulated debris. After cleaning, the cartridge is reinstalled, and the filter is returned to service.

Working Principle

Water enters the filter and passes through the fine screen. As it flows toward the outlet, contaminants gradually accumu - late on the inner surface of the screen. This buildup creates a pressure difference between the inlet and outlet. To ensure proper performance, the filter must be cleaned by the time the pressure difference reaches 0.7 bar.

ADVANTAGES

Powerful Filtration, Smarter Design.

The Power of Capacity. The Simplicity of Design.

When your system demands higher flow rates, the LE Manual Screen Filter delivers. Its high-capacity body is engineered to maximize the screen's surface area, enabling significantly greater throughput than standard designs. It maintains the elegant, motor-free principle of our manual series, operating solely on your system's pressure for energy-free, low-maintenance performance. Engineered for durability, this is the definitive solution for your most challenging applications.

DÖKÜMANLAR

| CODE | Inch | mm | Flow Rate | Weight kg |

|||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| D | D1 | M | T | A | B | L | L1 | m³/h | GPM(US) | ||

| LE50 | 5 | 10 | 1/4 | 1 | 610 | 287 | 1055 | 640 | 140 | 616 | 46 |

| LE60 | 6 | 10 | 1/4 | 1 | 710 | 287 | 1255 | 840 | 180 | 792 | 58 |

| LE60S | 6 | 12 | 1/4 | 1 | 810 | 287 | 1455 | 1040 | 220 | 968 | 68 |

| LE80 | 8 | 12 | 1/4 | 1 | 810 | 287 | 1455 | 1040 | 280 | 1232 | 70 |

| LE80S | 8 | 12 | 1/4 | 1 | 930 | 312 | 1690 | 1275 | 340 | 1496 | 88 |