| Body Material | PVC-HDPE |

| Nozzle Material | POM |

| Screen / Filter Material | SS304L |

| Maximum Vacuum Pressure | 8 bar; 116 Psi |

| Minimum Vacuum Pressure | 3 bar; 43.5 Psi |

| Maximum Operating Temperature | 60 °C; 140°F |

| Control System | Continuous Cleaning |

| Filtering Sensitivity | 2000 μ (micron) |

Ürünlerimiz

water_drop Irrigation

Uygulama Alanları

water_drop IRRIGATION

Filter Types

Media Center

Send us a message

Fill out the form below to contact us.

Cleaning Process

Pressurized water supplied from the auxiliary line is directed through nozzles to drive the circular motion of the screen system. This continuous movement scours the screen surface, effectively removing contaminants as they approach. As a result, the screen surface remains constantly clean, ensuring uninterrupted filtration.

Working Principle

The DSF Suction Filter operates on the suction side of a pump, providing coarse filtration at 2000 microns to protect the pump from large debris drawn from open water sources. Its key operational feature is a dynamic, continuously moving screen system designed to prevent clogging. This screen mechanism is hydraulically actuated by a dedicated auxiliary line that taps into the pump’s pressurized discharge. This auxiliary line is intentionally designed with a smaller diameter than the filter’s main connection. This design ensures the necessary pressure and flow velocity are generated to reliably power the screen’s continuous movement, allowing for uninterrupted filtration.

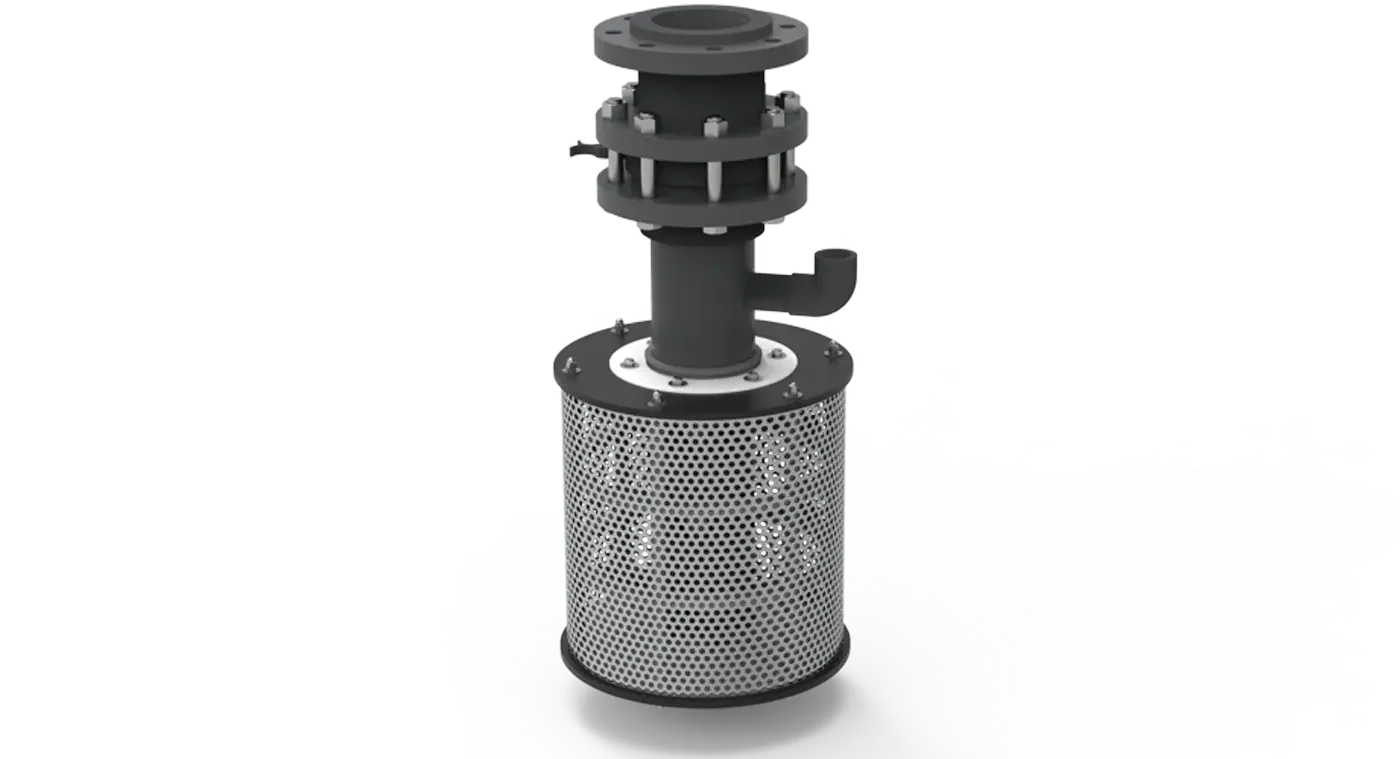

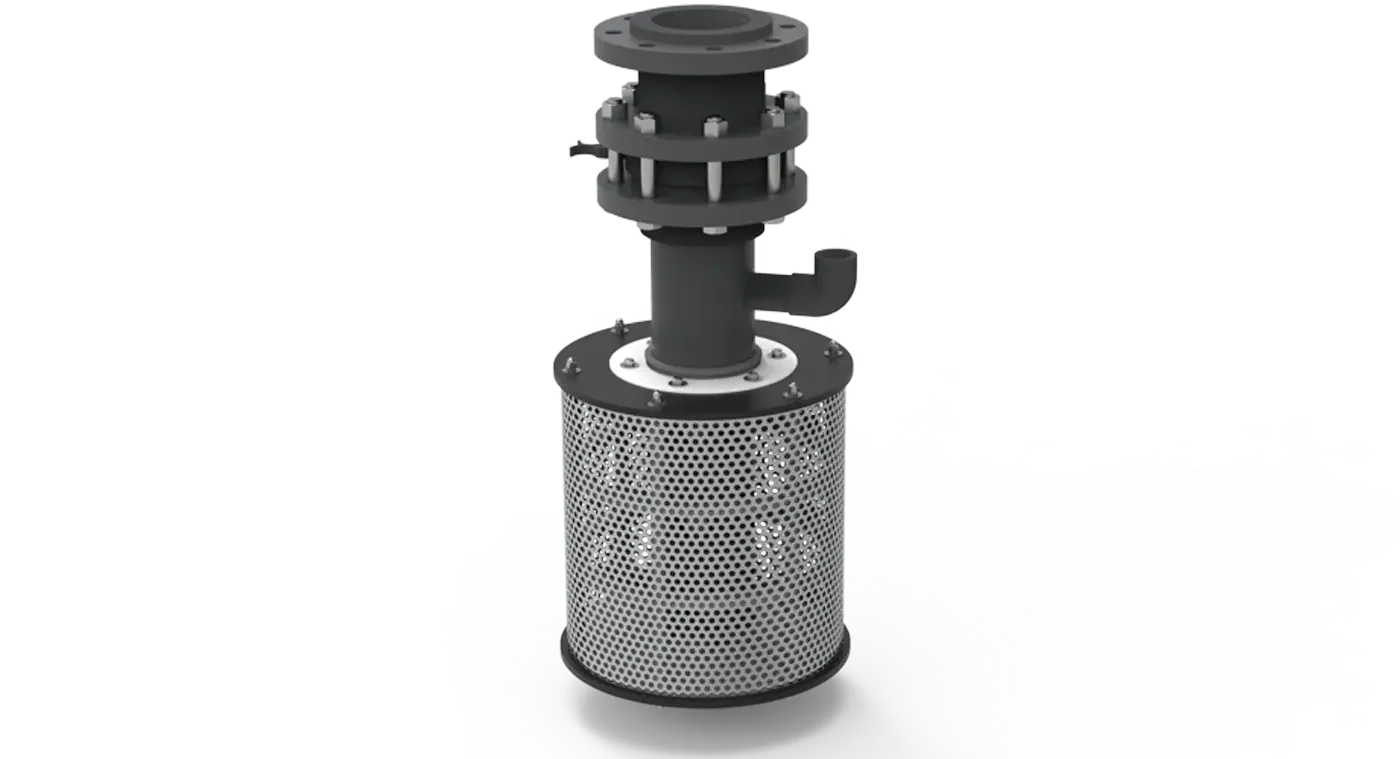

DSF Series - Self-Cleaning Suction Filters

GENERAL FEATURES

| Body Material | PVC-HDPE |

| Nozzle Material | POM |

| Screen / Filter Material | SS304L |

| Maximum Vacuum Pressure | 8 bar; 116 Psi |

| Minimum Vacuum Pressure | 3 bar; 43.5 Psi |

| Maximum Operating Temperature | 60 °C; 140°F |

| Control System | Continuous Cleaning |

| Filtering Sensitivity | 2000 μ (micron) |

ADVANTAGES

Cleaning Process

Pressurized water supplied from the auxiliary line is directed through nozzles to drive the circular motion of the screen system. This continuous movement scours the screen surface, effectively removing contaminants as they approach. As a result, the screen surface remains constantly clean, ensuring uninterrupted filtration.

Working Principle

The DSF Suction Filter operates on the suction side of a pump, providing coarse filtration at 2000 microns to protect the pump from large debris drawn from open water sources. Its key operational feature is a dynamic, continuously moving screen system designed to prevent clogging. This screen mechanism is hydraulically actuated by a dedicated auxiliary line that taps into the pump’s pressurized discharge. This auxiliary line is intentionally designed with a smaller diameter than the filter’s main connection. This design ensures the necessary pressure and flow velocity are generated to reliably power the screen’s continuous movement, allowing for uninterrupted filtration.

DSF Series - Self-Cleaning Suction Filters

ADVANTAGES

Your Pump’s First Line of Defense.

Positioned at the very start of your system, the Aytok suction filter acts as a rugged guardian for your pump. It is designed to handle raw water sources with heavy contaminants like algae, garbage, and sand. By capturing this debris before it can cause damage, it prevents costly failures, minimizes downtime, and ensures the long-term health and efficiency of your entire irrigation infrastructure.

GENERAL FEATURES

| Body Material | PVC-HDPE |

| Nozzle Material | POM |

| Screen / Filter Material | SS304L |

| Maximum Vacuum Pressure | 8 bar; 116 Psi |

| Minimum Vacuum Pressure | 3 bar; 43.5 Psi |

| Maximum Operating Temperature | 60 °C; 140°F |

| Control System | Continuous Cleaning |

| Filtering Sensitivity | 2000 μ (micron) |

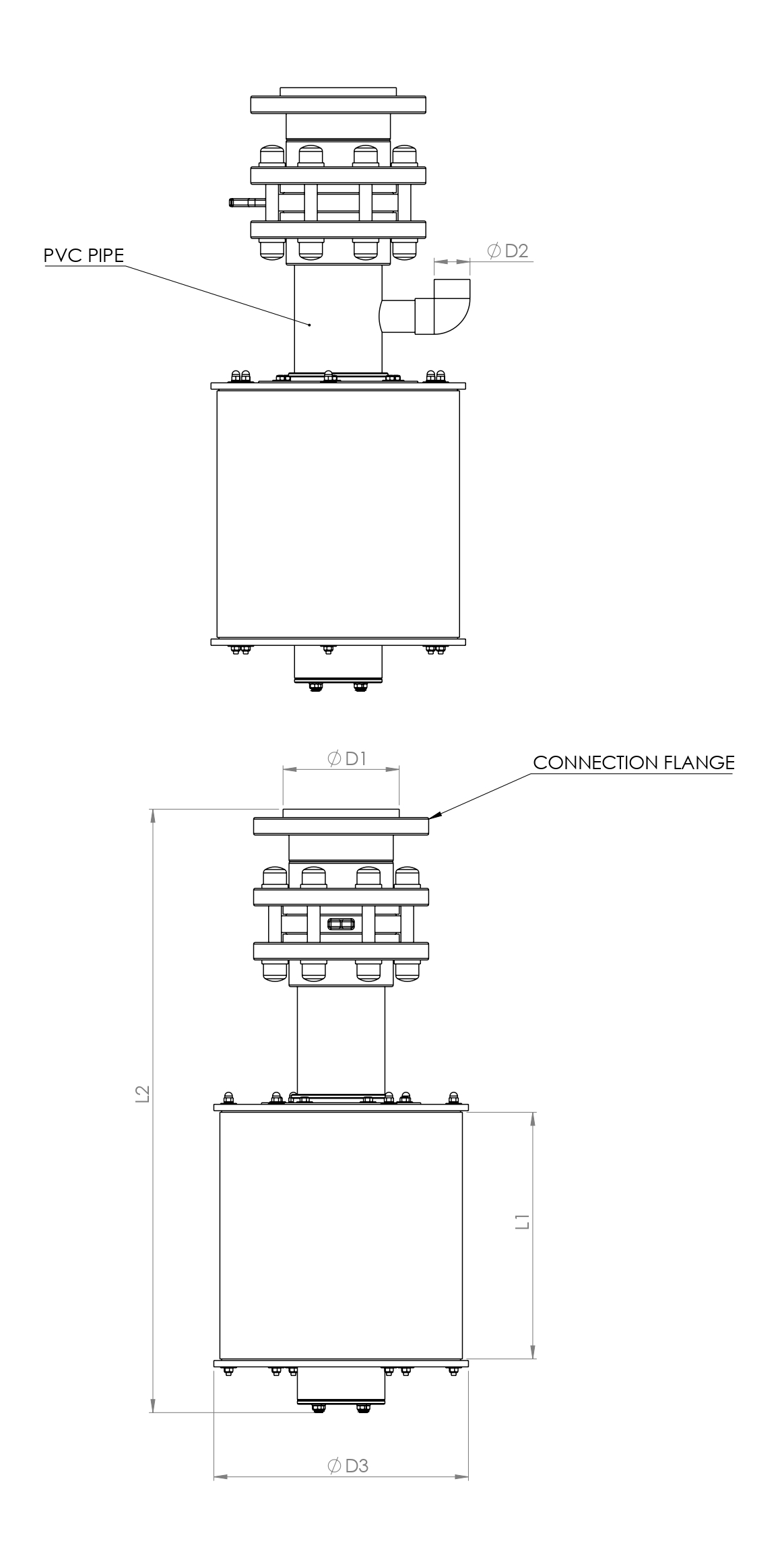

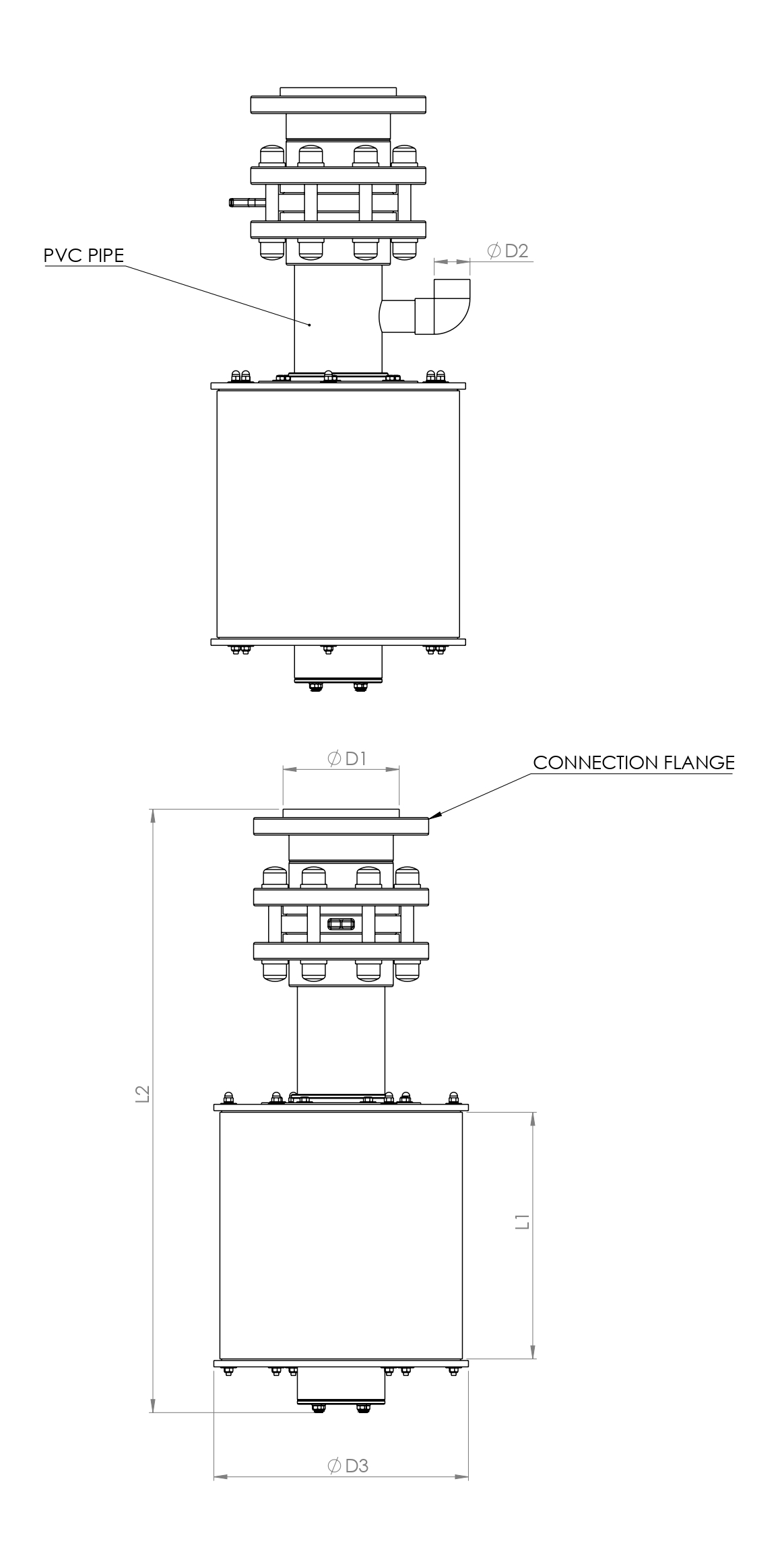

| CODE | D1 | D2 | D3 | L1 | L2 | Flow Rate | Supply Flow Rate | Weight | ||

|---|---|---|---|---|---|---|---|---|---|---|

| m³/h | GPM(US) | L/s | GPM(US) | |||||||

| DSF4 | 4 | 100 | 1 | 310 | 305 | 90 | 396 | 0,8 | 12,6 | 13,8 |

| DSF6 | 6 | 150 | 1 1/2 | 410 | 405 | 165 | 726 | 1,8 | 28,5 | 26 |

| DSF8 | 8 | 200 | 2 | 510 | 510 | 330 | 1452 | 3,6 | 57 | 44,6 |

Send us a message

Fill out the form below to contact us.

Ürün Detayı

DSF Series - Self-Cleaning Suction Filters

GENERAL FEATURES

Cleaning Process

Pressurized water supplied from the auxiliary line is directed through nozzles to drive the circular motion of the screen system. This continuous movement scours the screen surface, effectively removing contaminants as they approach. As a result, the screen surface remains constantly clean, ensuring uninterrupted filtration.

Working Principle

The DSF Suction Filter operates on the suction side of a pump, providing coarse filtration at 2000 microns to protect the pump from large debris drawn from open water sources. Its key operational feature is a dynamic, continuously moving screen system designed to prevent clogging. This screen mechanism is hydraulically actuated by a dedicated auxiliary line that taps into the pump’s pressurized discharge. This auxiliary line is intentionally designed with a smaller diameter than the filter’s main connection. This design ensures the necessary pressure and flow velocity are generated to reliably power the screen’s continuous movement, allowing for uninterrupted filtration.

ADVANTAGES

Powerful Filtration, Smarter Design.

Your Pump’s First Line of Defense.

Positioned at the very start of your system, the Aytok suction filter acts as a rugged guardian for your pump. It is designed to handle raw water sources with heavy contaminants like algae, garbage, and sand. By capturing this debris before it can cause damage, it prevents costly failures, minimizes downtime, and ensures the long-term health and efficiency of your entire irrigation infrastructure.

DÖKÜMANLAR

| CODE | D1 | D2 | D3 | L1 | L2 | Flow Rate | Supply Flow Rate | Weight | ||

|---|---|---|---|---|---|---|---|---|---|---|

| m³/h | GPM(US) | L/s | GPM(US) | |||||||

| DSF4 | 4 | 100 | 1 | 310 | 305 | 90 | 396 | 0,8 | 12,6 | 13,8 |

| DSF6 | 6 | 150 | 1 1/2 | 410 | 405 | 165 | 726 | 1,8 | 28,5 | 26 |

| DSF8 | 8 | 200 | 2 | 510 | 510 | 330 | 1452 | 3,6 | 57 | 44,6 |