| Body Material | S235JR / SS304L / SS316L |

| Screen Material (Internal Kit) | SS304L, PA6GFR30 |

| Maximum Working Pressure | 10 bar ; 145 Psi |

| Minimum Working Pressure | 1 bar ; 14.5 Psi |

| Maximum Working Temperature | 60 °C ; 140°F |

| Control System | Semi Automatic Control |

| Filtration Sensitivity | 20-2000 μ (micron) |

| Painting Method | Electrostatic Powder Coating |

| Paint Coating Material | Epoxy-Polyester |

Ürün Detayı

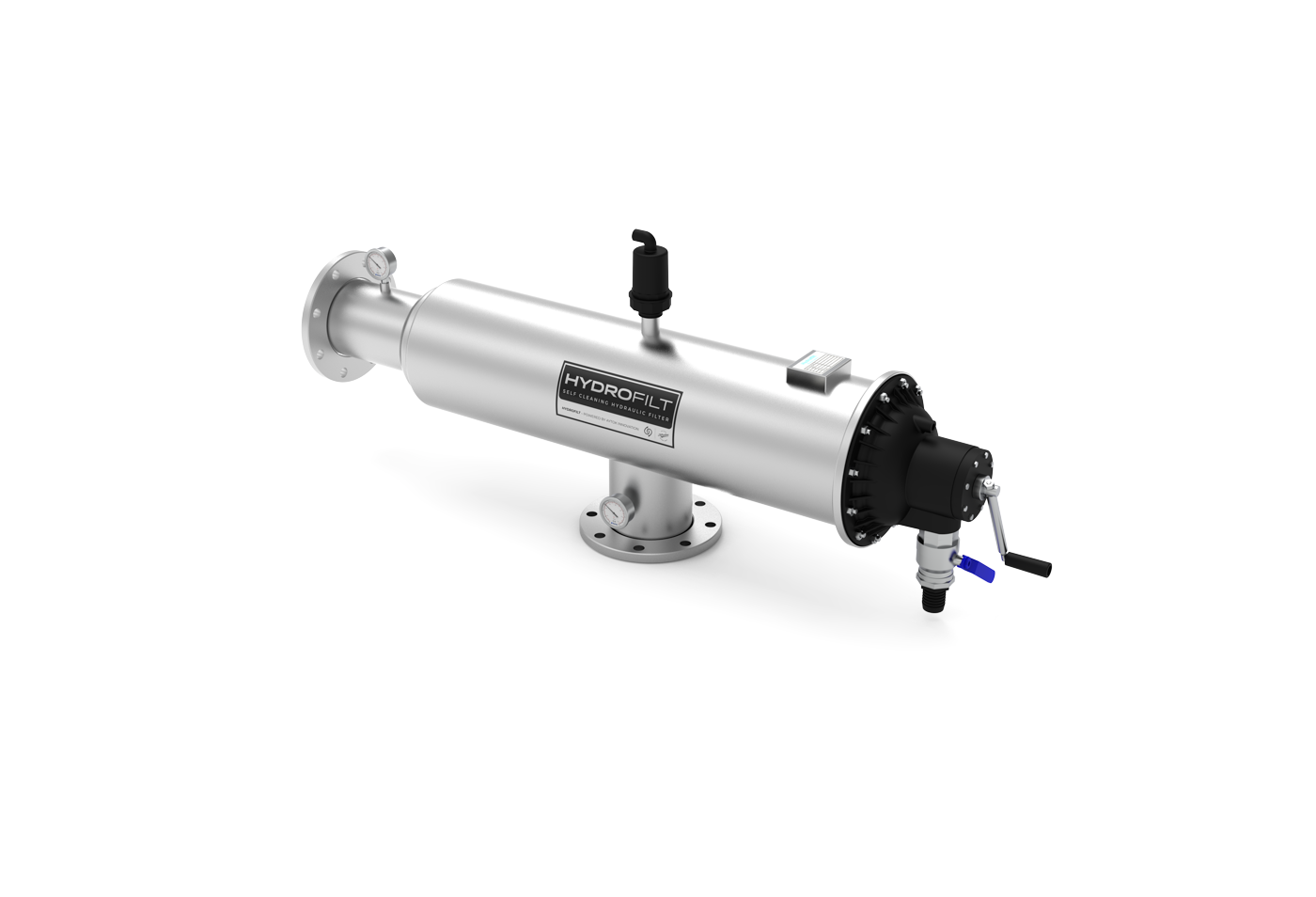

MF Series - Semi-Automatic Metal Screen Filters

GENERAL FEATURES

Cleaning Process

The cleaning cycle is a simple, operator-initiated process: 1.Open the Drain Valve: The operator opens the drain valve. This creates a pressure drop inside the filter's collector, resulting in a strong suction force at the cleaning nozzles. 2.Turn the Hand Crank: While the valve is open, the operator slowly turns the hand crank. This rotates the internal suction-scanner, moving the nozzles across the entire surface of the screen. 3.Flush Contaminants: The suction from the nozzles pulls the accumulated dirt and particles off the screen and expels them through the open drain valve. The operator can observe the inlet and outlet manometers; as the screen gets cleaner, the pressure differential will decrease. 4.Close the Drain Valve: Once the pressure between the inlet and outlet has equalized, indicating a clean screen, the operator closes the drain valve. The filter is now operating at maximum efficiency.

Working Principle

Water enters through the inlet line and flows toward the outlet line of the filter. It first passes through a coarse screen for preliminary filtration, followed by a fine screen where particles are retained on its surface. During the cleaning process, accumulated contaminants are discharged through the drain line. The handle kit creates both linear and rotational motion, driving the cleaning collector. This allows the nozzles to scan the entire surface of the fine screen, suctioning particles that are then transported out through the collector. The combination of linear and rotational motion from the handle kit ensures complete coverage of the screen surfaces.

ADVANTAGES

Optional On-Line Model Configurations

Powerful Filtration, Smarter Design.

Effortless Cleaning, Uninterrupted Flow.

The MF series puts powerful, semi-auto - matic cleaning at your fingertips. Simply turn the handle to flush contaminants without shutting down your system. It’s the perfect solution for reducing labor and maximizing uptime, offering reliable filtration with smart, operator-initiated control.

DÖKÜMANLAR

| CODE | Inlet/Outlet | A | B | L1 | L | D | F | Drain Flow Rate | Main Flow Rate | Filtration Area cm² |

Nozzle Qty. |

Screen Qty. |

Weight kg |

|||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Inch | DN | mm | mm | mm | mm | Inch | Inch | L/s | GPM(US) | m³/h | GPM(US) | |||||

| MF/CMF102 | 2 | 50 | 390 | 270 | 365 | 1010 | 10 | 2 | 3,3 | 53 | 40 | 176 | 1317 | 2 | 2 | 36 |

| MF/CMF1025 | 2 1/2 | 65 | 390 | 270 | 365 | 1010 | 10 | 2 | 3,3 | 53 | 50 | 220 | 1317 | 2 | 2 | 37 |

| MF/CMF103 | 3 | 80 | 440 | 270 | 465 | 1110 | 10 | 2 | 4,1 | 66 | 70 | 308 | 1975 | 3 | 3 | 41 |

| MF/CMF104 | 4 | 100 | 580 | 270 | 570 | 1210 | 10 | 2 | 5 | 79 | 120 | 528 | 2634 | 4 | 4 | 48 |

| MF/CMF105 | 5 | 125 | 680 | 287 | 770 | 1400 | 10 | 2 | 4,1 | 66 | 150 | 660 | 3951 | 3 | 6 | 57 |

| MF/CMF106 | 6 | 150 | 780 | 287 | 970 | 1600 | 10 | 2 | 5 | 79 | 180 | 792 | 5268 | 4 | 8 | 67 |

| MF/CMF126S | 6 | 150 | 985 | 312 | 1390 | 2020 | 12 | 2 | 6,6 | 106 | 220 | 968 | 7902 | 6 | 12 | 123 |

| MF/CMF128 | 8 | 200 | 985 | 312 | 1390 | 2020 | 12 | 2 | 6,6 | 106 | 340 | 1496 | 7902 | 6 | 12 | 127 |