| Body Material | S235JR / SS304L / SS316L |

| Screen Material (Internal Kit) | SS304L, PA6GFR30 |

| Maximum Working Pressure | 10bar ; 145Psi |

| Minimum Working Pressure | 1 bar ; 14.5 Psi |

| Maximum Working Temperature | 60 °C ; 140°F |

| Back Washing Time | Time and Pressure Difference Setup |

| Control System | Electronic (AC) |

| Filtration Sensitivity | 20-2000 μ (micron) |

| Painting Method | Electrostatic Powder Coating |

| Paint Coating Material | Epoxy-Polyester |

Ürün Detayı

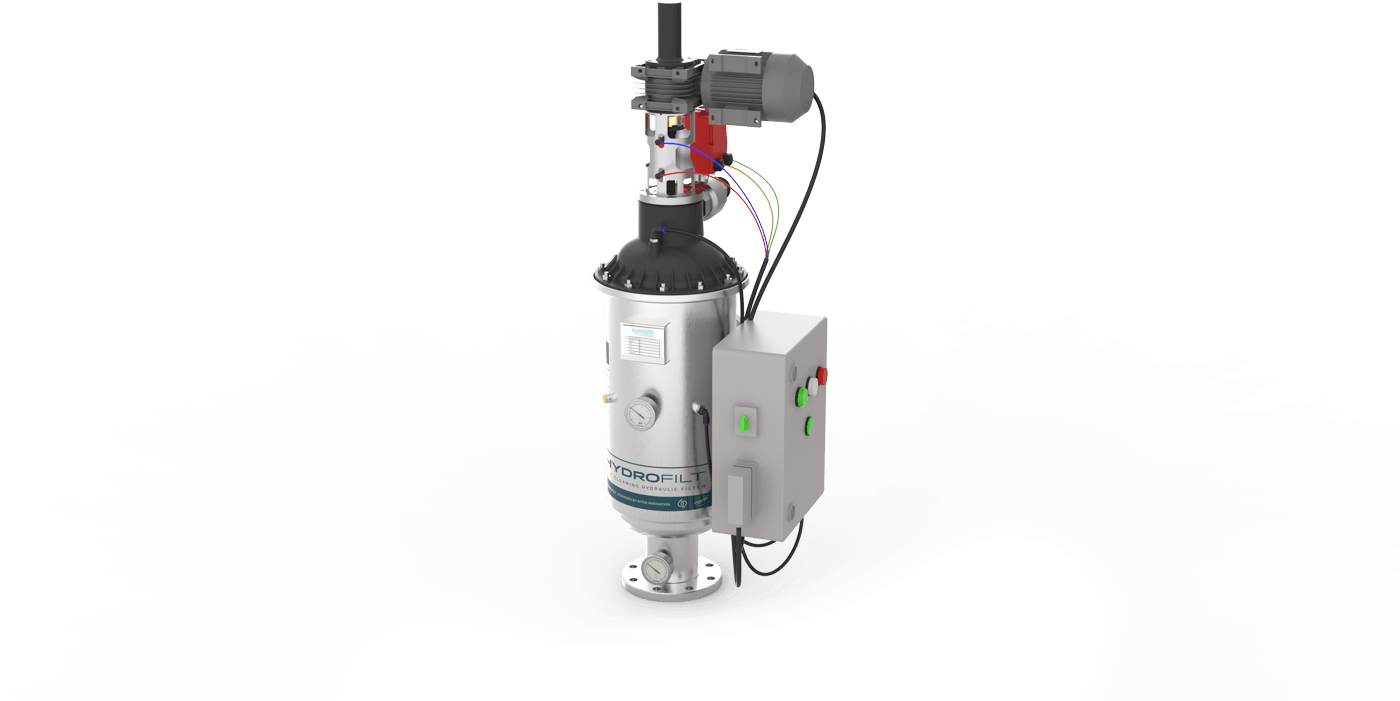

VRF Series - Vertical Self-Cleaning Filter with Motor Reducers

GENERAL FEATURES

Cleaning Process

The cleaning process is initiated either after a predefined time interval or when the differential pressure across the screen reaches the set threshold. Once triggered, the discharge line automatically opens via the actuator valve, and the control unit activates the backwash cycle. As the discharge line opens, a strong vacuum effect is generated at the washing manifold and nozzles near the screen surface. This vacuum suctions the particles retained on the screen and discharges them into the atmosphere. To ensure complete coverage of the screen surface, adjustable position sensors are installed. These sensors act as limiters for the AC motor with gearbox, which provides both circular and linear motion. The combination of these movements guarantees that the entire screen surface is scanned and thoroughly cleaned. Once the motor automatically completes its forward and backward movements, the cleaning cycle ends and the discharge line closes. During backwashing, filtration continues without interruption.

Working Principle

Water enters the filtration system through the inlet line. It first passes through a coarse screen for preliminary filtration, then flows into the fine screen for final filtration. The clean water is then discharged from the outlet line to the clean water network. As water flows through the fine screen, suspended particles accumulate on its inner surface. This accumulation gradually creates a differential pressure across the screen, which serves as the trigger for the automated backwash process.

ADVANTAGES

Powerful Filtration, Smarter Design.

Don’t Let Low Pressure Compromise Your Filtration.

The VRF series excels where others fail, delivering powerful, automatic self-cleaning at pressures as low as 1 bar. Its system ensures uninterrupted operation by cleaning itself while filtering, all in a smart, space-saving vertical design that maximizes performance.

DÖKÜMANLAR

| CODE | Inlet/Outlet | A | B | L1 | L | D | F | Drain Flow Rate | Main Flow Rate | Filtration Area cm² |

Nozzle Qty. |

Screen Qty. |

Weight kg |

|||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Inch | DN | mm | mm | mm | mm | Inch | Inch | L/s | GPM(US) | m³/h | GPM(US) | |||||

| VRF/CVRF102F | 2 | 50 | 310 | 270 | 205 | 1022 | 10 | 2 | 3,3 | 53 | 30 | 132 | 658 | 2 | 1 | 27 |

| VRF/CVRF1025F | 2 1/2 | 65 | 310 | 270 | 205 | 1022 | 10 | 2 | 3,3 | 53 | 40 | 176 | 658 | 2 | 1 | 28 |

| VRF/CVRF102 | 2 | 50 | 390 | 270 | 365 | 1182 | 10 | 2 | 3,3 | 53 | 40 | 176 | 1317 | 2 | 2 | 43 |

| VRF/CVRF1025 | 2 1/2 | 65 | 390 | 270 | 365 | 1182 | 10 | 2 | 3,3 | 53 | 50 | 220 | 1317 | 2 | 2 | 44 |

| VRF/CVRF103 | 3 | 80 | 390 | 270 | 365 | 1182 | 10 | 2 | 3,3 | 53 | 55 | 242 | 1317 | 2 | 2 | 45 |

| VRF/CVRF103S | 3 | 80 | 440 | 270 | 465 | 1282 | 10 | 2 | 4,1 | 66 | 70 | 308 | 1975 | 3 | 3 | 48 |

| VRF/CVRF104 | 4 | 100 | 440 | 270 | 465 | 1282 | 10 | 2 | 4,1 | 66 | 100 | 440 | 1975 | 3 | 3 | 50 |

| VRF/CVRF104S | 4 | 100 | 490 | 270 | 565 | 1432 | 10 | 2 | 5 | 79 | 120 | 528 | 2634 | 4 | 4 | 52 |

| VRF/CVRF105 | 5 | 125 | 690 | 287 | 880 | 2012 | 10 | 2 | 4,1 | 66 | 150 | 660 | 3951 | 3 | 6 | 60 |

| VRF/CVRF105S | 5 | 125 | 840 | 287 | 1080 | 2212 | 10 | 2 | 5 | 79 | 160 | 704 | 5268 | 4 | 8 | 132 |

| VRF/CVRF106 | 6 | 150 | 840 | 287 | 1080 | 2212 | 10 | 2 | 5 | 79 | 180 | 792 | 5268 | 4 | 8 | 135 |