| Body Material | PA6GFR30 |

| Cartridge Material | SS304L, PA6GFR30 |

| Maximum Working Pressure | 8 bar ; 116 Psi |

| Minimum Working Pressure | 1 bar ; 14.5 Psi |

| Maximum Working Temperature | 60 °C ; 140°F |

| Back Washing Time | Time and Pressure Difference Setup |

| Control System | Electronic (AC/DC) |

| Filtration Sensitivity | 20-200 μ (micron) |

Ürünlerimiz

water_drop Irrigation

Uygulama Alanları

water_drop IRRIGATION

Filter Türleri

Media Center

Cleaning Process

Contaminants suspended at the center of the screen by the water’s continuous circular motion are expelled through a discharge valve during the backwash cycle. The initiation of this cycle depends on the filter’s configuration. In fully automatic systems, a control unit manages the process by opening the valve and initiating backwash based on one of two userdefined settings: either when the pressure differential between the filter’s inlet and outlet reaches a preset threshold, or after a preset time interval has elapsed, whichever occurs first.

Working Principle

The operating principle of Hurricane Filters is based on cyclonic separation. As water enters the filter, it is guided by internal helix blades that induce a powerful circular motion, or vortex. This cyclonic action generates a centrifugal force that serves two purposes: it prevents contaminants from accumulating on the screen surface, thereby minimizing clogging, and it directs the suspended particles toward the center of the filter for collection.

Send us a message

Fill out the form below to contact us.

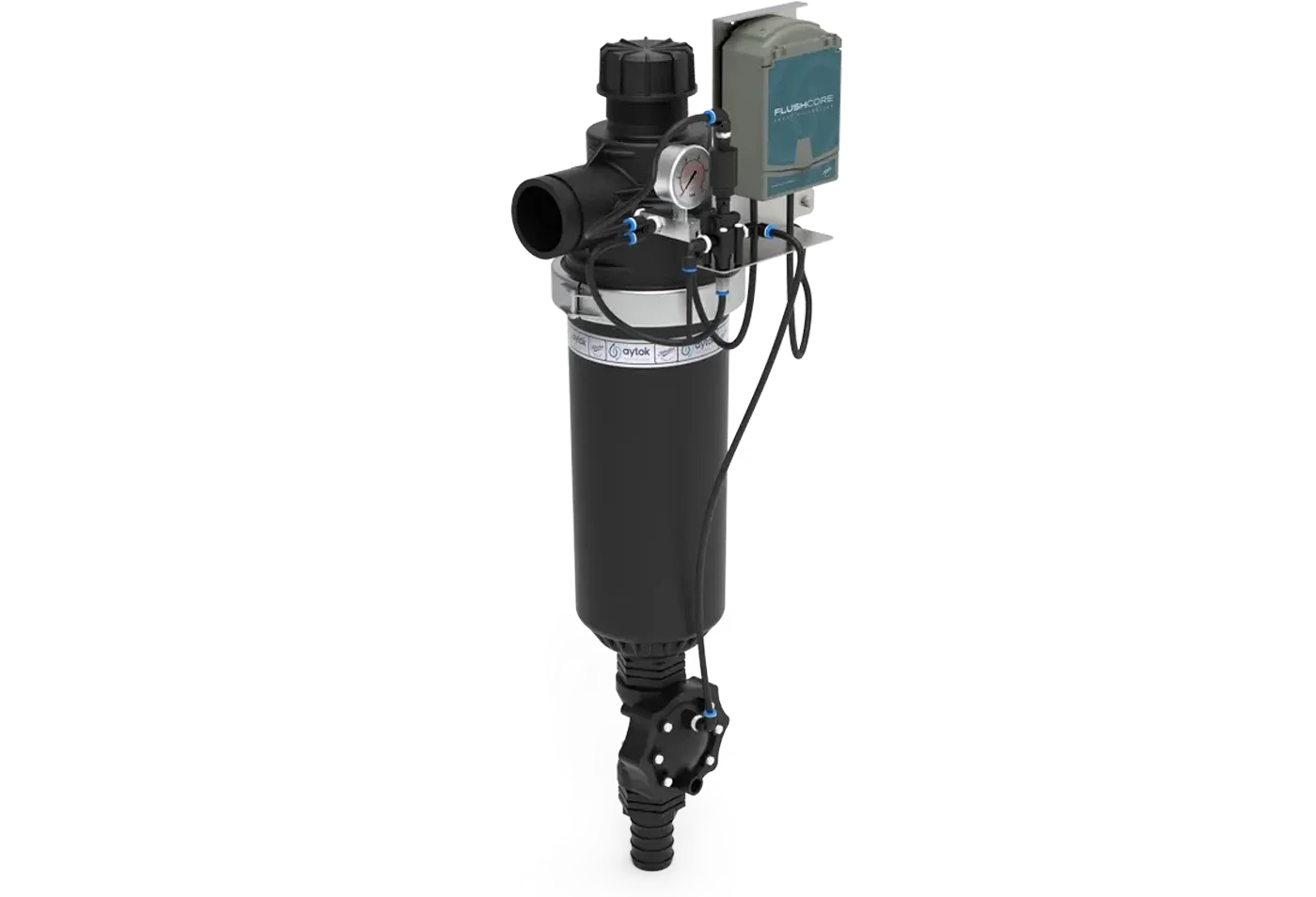

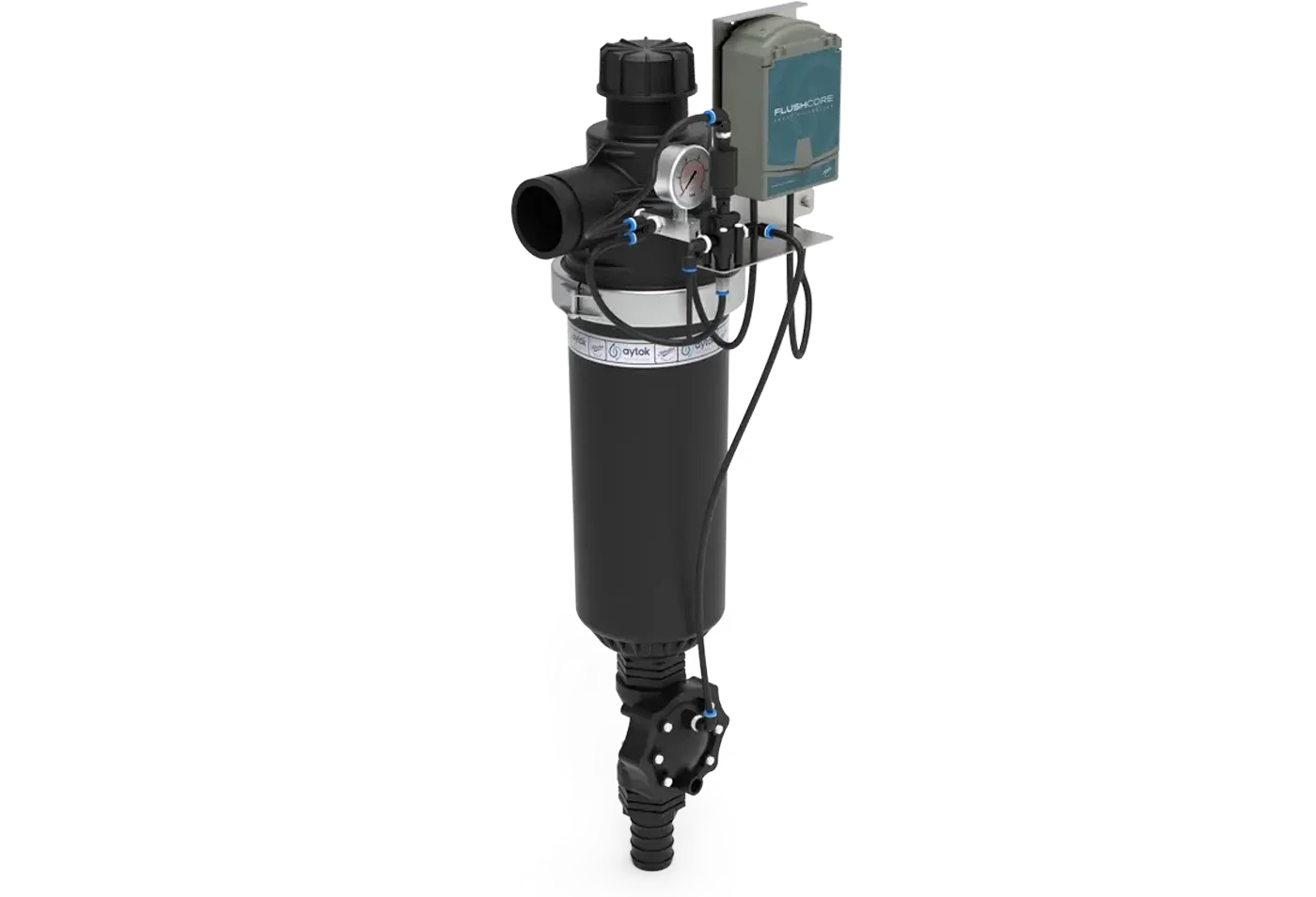

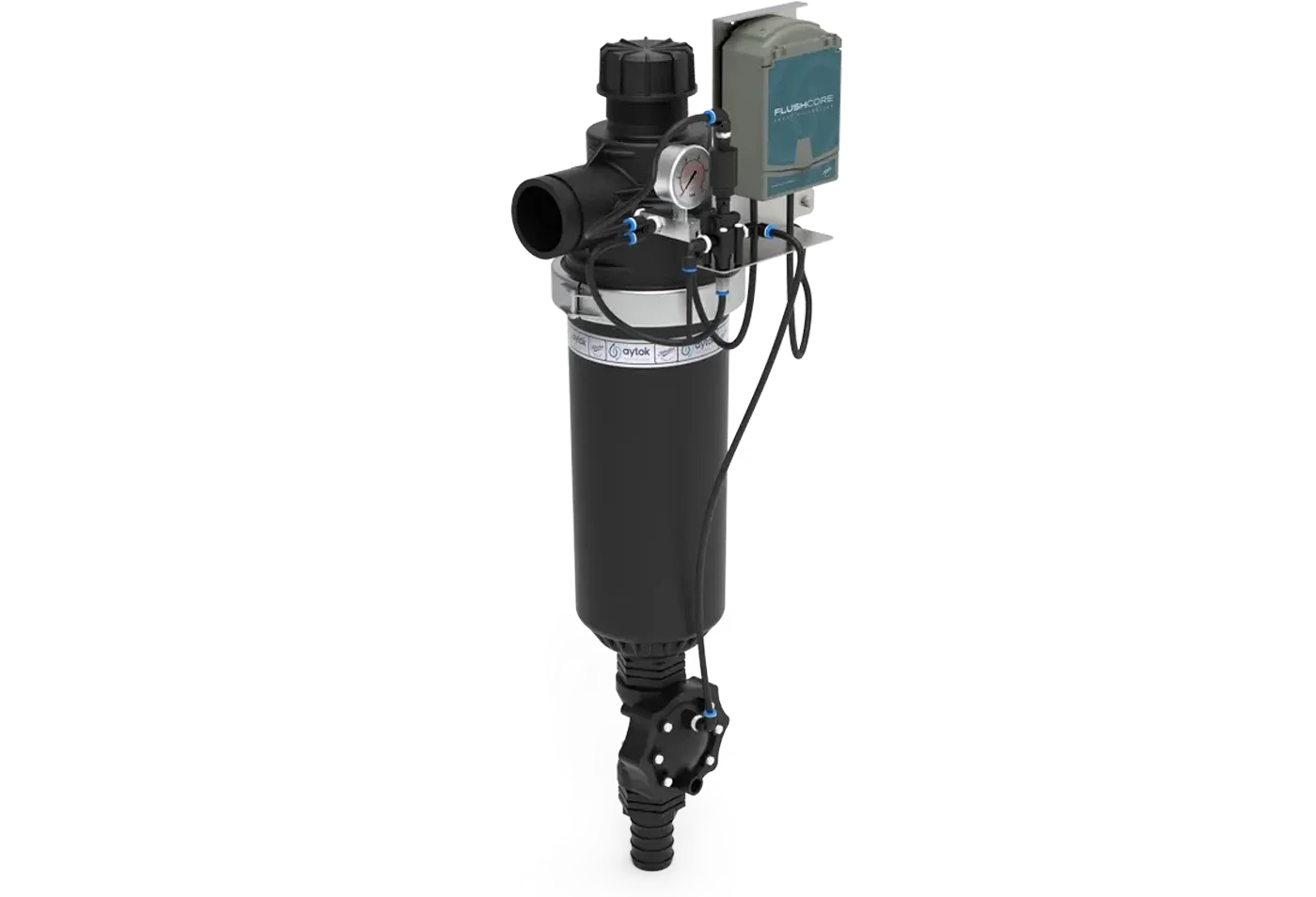

HP-A Serisi - T Model Otomatik Geri Yıkamalı Hurricanefilt

GENERAL FEATURES

| Body Material | PA6GFR30 |

| Cartridge Material | SS304L, PA6GFR30 |

| Maximum Working Pressure | 8 bar ; 116 Psi |

| Minimum Working Pressure | 1 bar ; 14.5 Psi |

| Maximum Working Temperature | 60 °C ; 140°F |

| Back Washing Time | Time and Pressure Difference Setup |

| Control System | Electronic (AC/DC) |

| Filtration Sensitivity | 20-200 μ (micron) |

ADVANTAGES

Cleaning Process

Contaminants suspended at the center of the screen by the water’s continuous circular motion are expelled through a discharge valve during the backwash cycle. The initiation of this cycle depends on the filter’s configuration. In fully automatic systems, a control unit manages the process by opening the valve and initiating backwash based on one of two userdefined settings: either when the pressure differential between the filter’s inlet and outlet reaches a preset threshold, or after a preset time interval has elapsed, whichever occurs first.

Working Principle

The operating principle of Hurricane Filters is based on cyclonic separation. As water enters the filter, it is guided by internal helix blades that induce a powerful circular motion, or vortex. This cyclonic action generates a centrifugal force that serves two purposes: it prevents contaminants from accumulating on the screen surface, thereby minimizing clogging, and it directs the suspended particles toward the center of the filter for collection.

Send us a message

Fill out the form below to contact us.

HP-A Serisi - T Model Otomatik Geri Yıkamalı Hurricanefilt

ADVANTAGES

Vortex-Powered Filtration.

Forget constant clogging and performance drops. The Aytok Hurricanefilt revolutionizes screen filtration with its dynamic vortex technology. Its powerful spiral flow continuously scours the screen, preventing particle buildup and ensuring consistent performance. The result: dramatically fewer backwash cycles, which significantly reduces both wastewater and maintenance costs, while ensuring a faster, more effective flush. It’s smarter filtration that works tirelessly, so you don’t have to.

GENERAL FEATURES

| Body Material | PA6GFR30 |

| Cartridge Material | SS304L, PA6GFR30 |

| Maximum Working Pressure | 8 bar ; 116 Psi |

| Minimum Working Pressure | 1 bar ; 14.5 Psi |

| Maximum Working Temperature | 60 °C ; 140°F |

| Back Washing Time | Time and Pressure Difference Setup |

| Control System | Electronic (AC/DC) |

| Filtration Sensitivity | 20-200 μ (micron) |

Ürün Detayı

HP-A Serisi - T Model Otomatik Geri Yıkamalı Hurricanefilt

GENERAL FEATURES

Cleaning Process

Contaminants suspended at the center of the screen by the water’s continuous circular motion are expelled through a discharge valve during the backwash cycle. The initiation of this cycle depends on the filter’s configuration. In fully automatic systems, a control unit manages the process by opening the valve and initiating backwash based on one of two userdefined settings: either when the pressure differential between the filter’s inlet and outlet reaches a preset threshold, or after a preset time interval has elapsed, whichever occurs first.

Working Principle

The operating principle of Hurricane Filters is based on cyclonic separation. As water enters the filter, it is guided by internal helix blades that induce a powerful circular motion, or vortex. This cyclonic action generates a centrifugal force that serves two purposes: it prevents contaminants from accumulating on the screen surface, thereby minimizing clogging, and it directs the suspended particles toward the center of the filter for collection.

ADVANTAGES

Powerful Filtration, Smarter Design.

Vortex-Powered Filtration.

Forget constant clogging and performance drops. The Aytok Hurricanefilt revolutionizes screen filtration with its dynamic vortex technology. Its powerful spiral flow continuously scours the screen, preventing particle buildup and ensuring consistent performance. The result: dramatically fewer backwash cycles, which significantly reduces both wastewater and maintenance costs, while ensuring a faster, more effective flush. It’s smarter filtration that works tirelessly, so you don’t have to.