Aytok Hydrofilt VRF/CVRF filters; are the filters that enable the movement of the collector pipe by the reducer electric motor and can discharge the dirty water by the motorized valve. These filters can perform fully automatic backwashing and can work by 220 and 380 Volt alternating current. ΔP (Pressure Difference) Sensor is used in the electronic control unit to detect the contamination and start the backwash. The opening of the motorized valve directed by the control unit, and the back and forth movement of the gearmotor by the rotational effect, ensures that the particles adhering to the inner surface of the screen are removed and discharged. When the gearmotor completes its cycle, the motorized valve closes and the process is completed. While this backwashing mechanism is operating, the filtering process continues. The dirty water formed in this process is automatically discharged during backwashing.

General Characteristics

Body Material: S195T / SS 316L / SS 304 L

Screen Material: SS 304L, PA6GFR30

Maximum Working Pressure: 10 Bar (145 PSI)

Minimum Working Pressure: 1 Bar (14.5 PSI)

Maximum Working Temperature : 60 °C (140 °F)

Back Flush Operation Criteria: Time and / or Pressure Differential

Back Flush Controlling Unit : Electronic (AC) Control

Filtration Degree: 20-2000 micron (µ)

Painting Method: Electrostratic Powder Coating

Painting Material: Epoxy Polyester

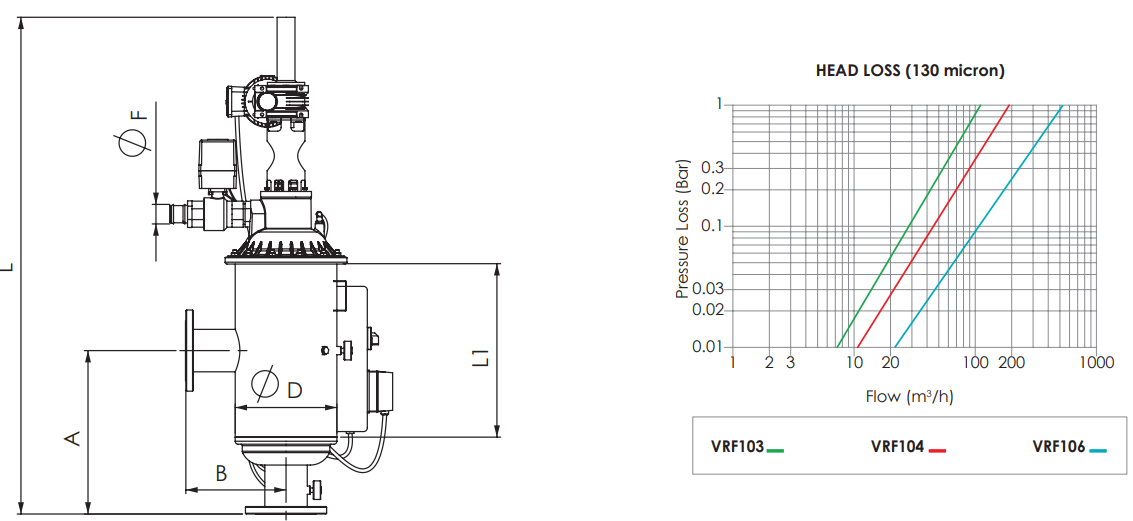

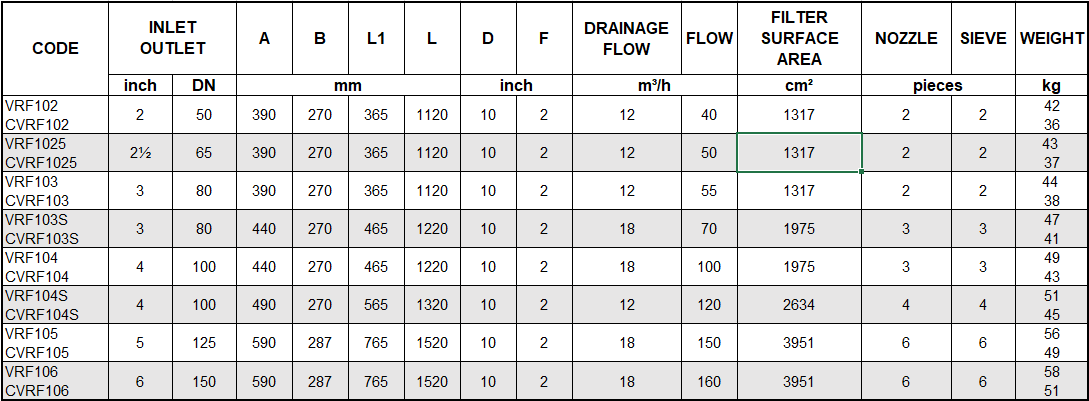

Technical Specification

Working Principle

The water entering the filter passes through the coarse screen and passes to the area where the fine screen filter is located. The water continues to flow from the fine screen to the outlet and creates a layer of pollution on the inner surface of the fine screen and this pollution causes a pressure difference at the inlet and outlet of the filter. The dirty layer on the screen surface causes difficulty on the water flow. This flow difficulty creates a pressure difference between the inlet and outlet. The difference value is detected by the ΔP sensor and transmitted to the control unit to start the washing. The Control Unit opens the motorized valve. While the motorized valve is discharging the dirty water; the control unit activates the motor. The circular movement of the gearmotor ensures a helical movement on the suction nozzles which are on the collector assembly make. The transmission of the movement is made with a square gear shaft. The movement of the reducer motor is controlled by optical sensors. Thus, the screen surface is completely scanned and the dirty layer is cleaned. The absorption of the dirty layer is made by the nozzles, as the system that opens to the atmosphere creates a vacuum effect in the filter. The sucked particles pass through the cover body by the collector assembly and are discharged out from the discharge section. The collector set returns to its starting position and continues the washing while returning also. The relief valve is closed and the cleaning process is completed. The filtration process is not interrupted during backwashing.